1. Introduction

In process automation, handheld communicators are essential tools for configuring, calibrating, and diagnosing smart field instruments. Among the most common communication protocols supported by these devices are HART (Highway Addressable Remote Transducer), BRAIN (Bit Rate Adjustable Intelligent Network), and Foundation Fieldbus (FF).

Understanding their differences in communication principles, features, and application scenarios is crucial for selecting the right protocol for specific projects.

2. HART Protocol

Background

Developed by Rosemount Inc. in 1985, the HART protocol is an open communication standard widely used in process industries. It combines analog and digital communication over the same wiring.

Technical Principle

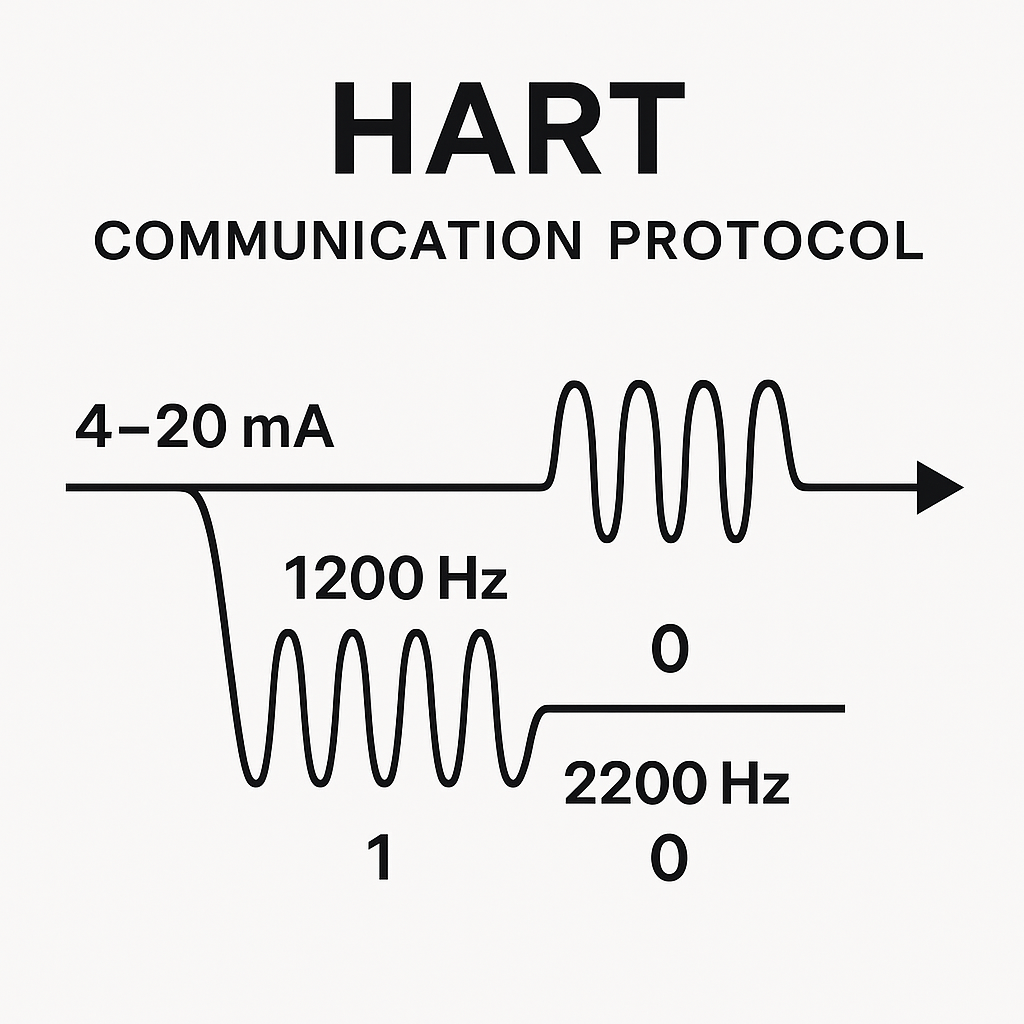

Technology: Frequency Shift Keying (FSK) based on the Bell 202 standard.

Signal: Digital data (1200 Hz for binary “1” and 2200 Hz for binary “0”) is superimposed on the 4–20 mA analog signal.

Non-intrusive: The average value of the FSK signal is zero, ensuring no interference with the analog measurement.

Data Rate: 1200 bps.

Communication Modes: Point-to-point, polling/response, and burst/broadcast modes. Supports multidrop connection for multiple devices.

Key Features

Wide vendor adoption; highly compatible across brands.

Requires matching software or firmware for version compatibility.

Allows configuration and diagnostics without interrupting process signals.

Application Scenarios

Retrofitting older 4–20 mA systems.

Situations requiring remote configuration and monitoring without rewiring.

3. BRAIN Protocol

Background

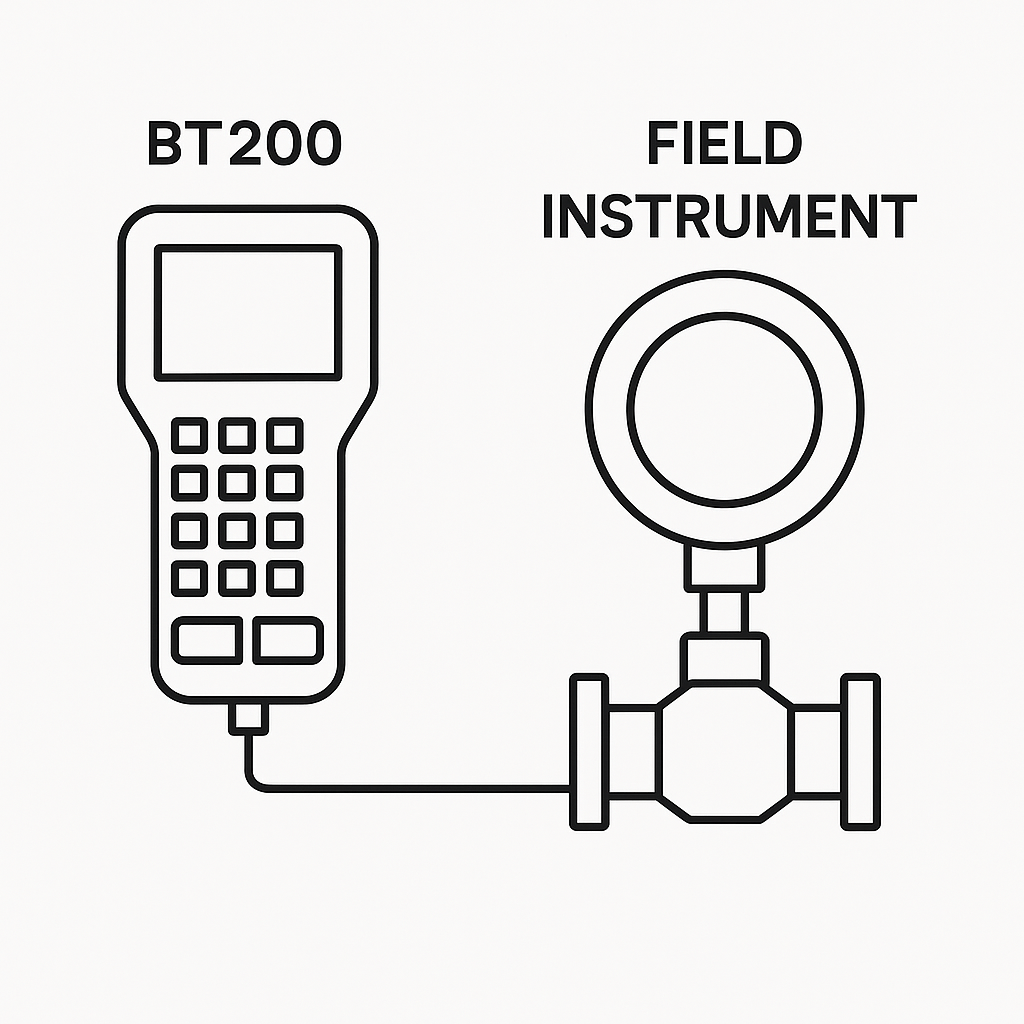

The BRAIN protocol is a proprietary standard developed by Yokogawa Electric Corporation for its intelligent transmitters, vortex flowmeters, electromagnetic flowmeters, and other instruments. It is supported by Yokogawa’s BT200 handheld communicator.

Technical Principle

Technology: Analog signal carrier communication, similar to HART in carrier and modulation method.

Data Rate: 1200 bps.

Parameter Storage: All parameters are stored in the field device; any BRAIN-compatible communicator can read/write them (if write access is enabled) without software upgrades.

Key Features

Proprietary to Yokogawa; limited to specific Yokogawa products.

No need for protocol software updates for device communication.

Robust parameter handling within the instrument itself.

Application Scenarios

Yokogawa-only installations.

Industries with long-term Yokogawa instrumentation standardization.

4. Foundation Fieldbus (FF) Protocol

Background

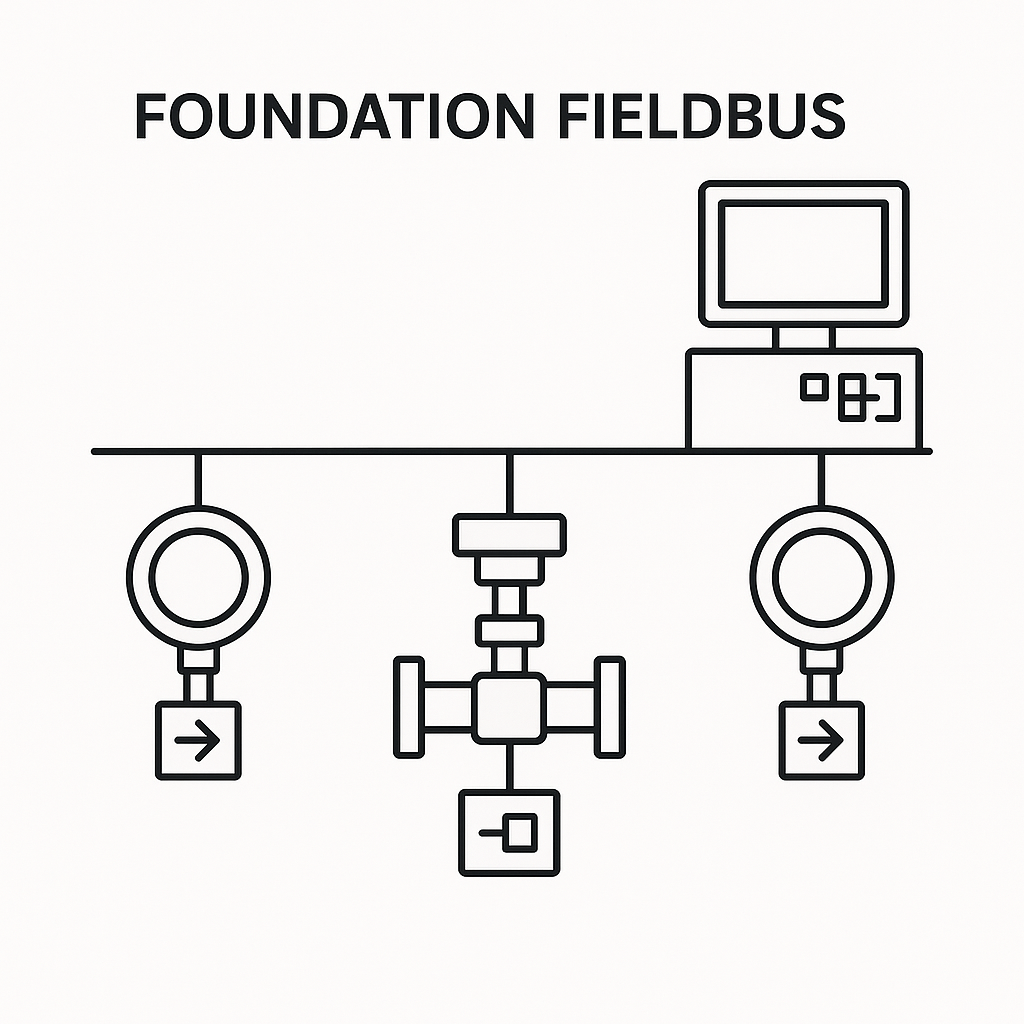

Foundation Fieldbus is an internationally standardized all-digital communication protocol developed by the FieldComm Group. It supports fully distributed control and integrates well with modern DCS systems.

Technical Principle

Architecture: Based on the ISO/OSI model (includes physical, data link, application, and user layers).

Data Rate: 31.25 kbps (H1 segment).

Wiring: Twisted pair cable, maximum 1900 m.

Function Blocks: Implements distributed control algorithms inside field devices.

Device Description (DD): Stores device parameters; system upgrades require updating configuration software and firmware.

Key Features

Fully digital, bidirectional, and supports redundancy for high reliability.

Enables control at the field level, reducing load on central controllers.

Well-suited for complex process automation.

Application Scenarios

Large-scale petrochemical plants and refineries.

Projects requiring high-speed, distributed, and redundant communication networks.

5. Protocol Comparison Table

| Parameter / Feature | HART | BRAIN | Foundation Fieldbus (FF) |

|---|---|---|---|

| Origin | Rosemount (1985) | Yokogawa | FieldComm Group |

| Type | Hybrid (Analog + Digital) | Analog carrier | Fully digital |

| Data Rate | 1200 bps | 1200 bps | 31.25 kbps |

| Wiring | 2-wire, 4–20 mA | 2-wire, 4–20 mA | Twisted pair |

| Compatibility | Multi-vendor | Yokogawa only | Multi-vendor |

| Communication Modes | Point-to-point, multidrop, burst | Point-to-point | Multi-drop, fully distributed |

| Parameter Storage | Device + host | Device only | Device (Function Blocks + DD) |

| Software/Firmware Updates | Sometimes required | Not required | Required for upgrades |

| Typical Application | Retrofitting and monitoring | Yokogawa-only plants | Large-scale DCS integration |

6. Conclusion

Each protocol has distinct strengths:

HART: Best for upgrading existing analog systems with minimal wiring changes.

BRAIN: Optimal for Yokogawa installations, ensuring full parameter access without software updates.

FF: Suitable for large-scale, distributed control systems requiring high-speed digital communication.

Selecting the right protocol depends on the vendor ecosystem, system architecture, and future scalability requirements.