Introduction

With the continuous advancement of industrial technology, hydrogen has become an important industrial gas widely used in power generation, chemical processing, electronics manufacturing, and other sectors. In these applications, accurate measurement of hydrogen humidity is essential for ensuring process safety and improving product quality.

A hydrogen gas humidity meter is a specialized instrument designed to measure the moisture content in hydrogen. Its measurement accuracy directly impacts process control, operational safety, and product performance. Therefore, regular calibration and verification of hydrogen humidity meters is a critical quality control procedure for many industries.

1. Working Principle of Hydrogen Humidity Meters

Hydrogen humidity meters determine the amount of water vapor present in hydrogen gas. Based on their measurement principle, they can be categorized into several types:

Capacitive Type – Uses a humidity-sensitive capacitor whose dielectric constant changes with humidity.

Resistive Type – Measures the change in resistance of a humidity-sensitive resistor in response to moisture content.

Optical Type – Often uses infrared absorption, detecting how water molecules absorb specific infrared wavelengths.

Regardless of the measurement principle, periodic calibration is necessary. Factors such as environmental conditions, prolonged use, and sensor aging can cause measurement drift, leading to inaccurate readings. Establishing a scientific calibration and verification system ensures data reliability and supports consistent process quality.

2. Common Calibration Methods for Hydrogen Humidity Meters

2.1 Standard Humidity Generator Method

One of the most widely used methods, this approach involves a precision standard humidity generator that produces gas with a known humidity level. The hydrogen humidity meter under test is placed in this controlled environment for comparison measurements.

Accuracy: Uncertainty typically within ±1% RH.

Procedure: Calibration is performed at multiple humidity set points (e.g., 20% RH, 50% RH, 80% RH) to evaluate overall performance.

Applications: Suitable for most industrial calibration needs.

2.2 Chilled Mirror (Dew Point) Method

A primary reference method based on the dew point principle, offering very high accuracy. The test gas is cooled until condensation forms on a mirror surface, and the temperature at this point is precisely measured.

Accuracy: Dew point measurement uncertainty as low as ±0.1 °C.

Advantages: Direct physical measurement, high precision.

Applications: High-end calibration labs, reference standards.

2.3 Electrolytic Method

Based on Faraday’s law of electrolysis, this method is particularly effective for low-humidity measurements. Moisture in the gas is absorbed by a desiccant such as phosphorus pentoxide, then electrolytically decomposed into hydrogen and oxygen.

Range: 0–1000 ppm moisture.

Accuracy: Uncertainty within ±5% of reading.

Applications: Ultra-low humidity environments, micro-moisture analysis.

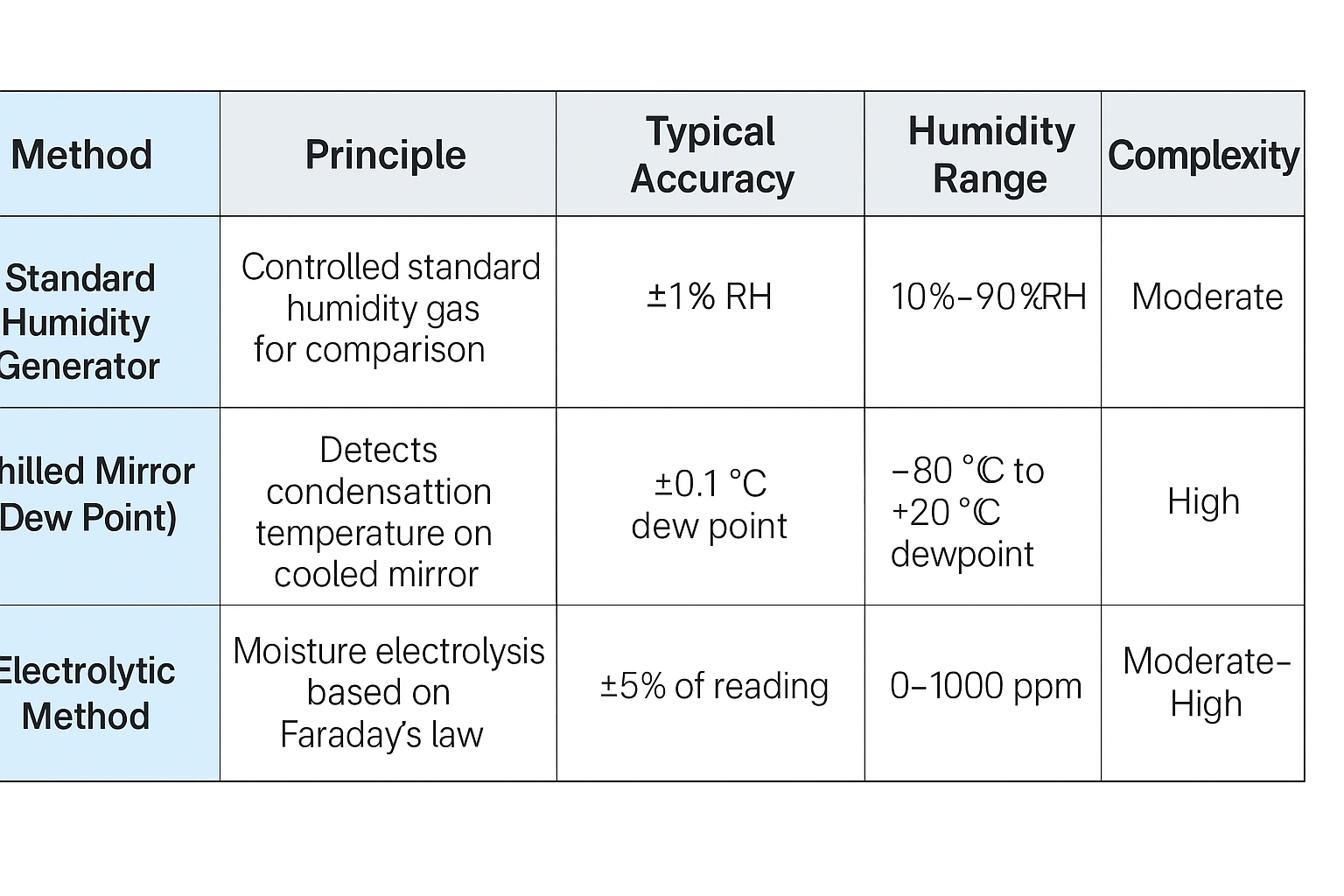

3. Comparison of Calibration Methods

| Method | Principle | Typical Accuracy | Humidity Range | Complexity | Best for |

|---|---|---|---|---|---|

| Standard Humidity Generator | Controlled standard humidity gas for comparison | ±1% RH | 10%–90% RH | Moderate | General industrial calibration |

| Chilled Mirror (Dew Point) | Detects condensation temperature on cooled mirror | ±0.1 °C dew point | -80 °C to +20 °C dew point | High | Laboratory reference, high-precision requirements |

| Electrolytic Method | Moisture electrolysis based on Faraday’s law | ±5% of reading | 0–1000 ppm | Moderate–High | Ultra-low humidity and micro-moisture measurement |

4. Measures to Improve Calibration Accuracy

Controlled Calibration Environment

Maintain laboratory temperature at 23 ± 2 °C and relative humidity at 50 ± 10% RH.

Allow equipment to warm up for at least 30 minutes before testing.

Minimize vibration, airflow, and electromagnetic interference.

Apply atmospheric pressure compensation if needed.

Selection and Maintenance of Reference Standards

Reference devices should have three times better accuracy than the unit under test.

Perform traceable verification of reference devices at least once a year.

Maintain and clean equipment, replace desiccants regularly for electrolytic hygrometers.

Standardized Calibration Procedure

Record instrument model, serial number, and environmental conditions before calibration.

Test from low to high humidity levels, allowing each point to stabilize.

Repeat measurements at least three times per point and take the average.

Document all results, including raw data and reference instrument details.

Clearly tag any non-compliant instruments and recommend repair or decommissioning.

5. Recommended Calibration Laboratory Layout

Central Calibration Bench – Equipped with standard humidity generator, chilled mirror hygrometer, and electrolytic hygrometer.

Environmental Control Zone – Temperature and humidity-controlled chamber ensuring stable calibration conditions.

Reference Equipment Storage – Isolated, dust-free cabinet for storing reference devices when not in use.

Data Logging & Analysis Station – Computer and software for real-time data acquisition, statistical processing, and report generation.

Safety and Gas Handling Area – Hydrogen handling safety cabinet, gas flow control units, and emergency shutoff valves.

Conclusion

The calibration and verification of hydrogen humidity meters is vital for ensuring measurement accuracy, operational safety, and process quality control. By applying appropriate calibration methods such as the standard humidity generator, chilled mirror, and electrolytic techniques, performance can be accurately assessed.

A well-controlled calibration environment, high-quality reference instruments, and strict procedural discipline will significantly improve calibration reliability. As measurement technologies evolve, calibration standards and methods should be continually refined to meet higher industrial demands.

Regular, standardized calibration not only ensures optimal instrument performance but also prevents potential safety hazards—making it an essential practice for industries relying on hydrogen processes.