The measurement accuracy of a tungsten-cobalt alloy wear-resistant thermocouple is not determined by the tungsten-cobalt alloy sheath material itself. Instead, it depends on the thermocouple core type, overall structural design, and installation and operating conditions.

1. Key Factor: Thermocouple Core Type

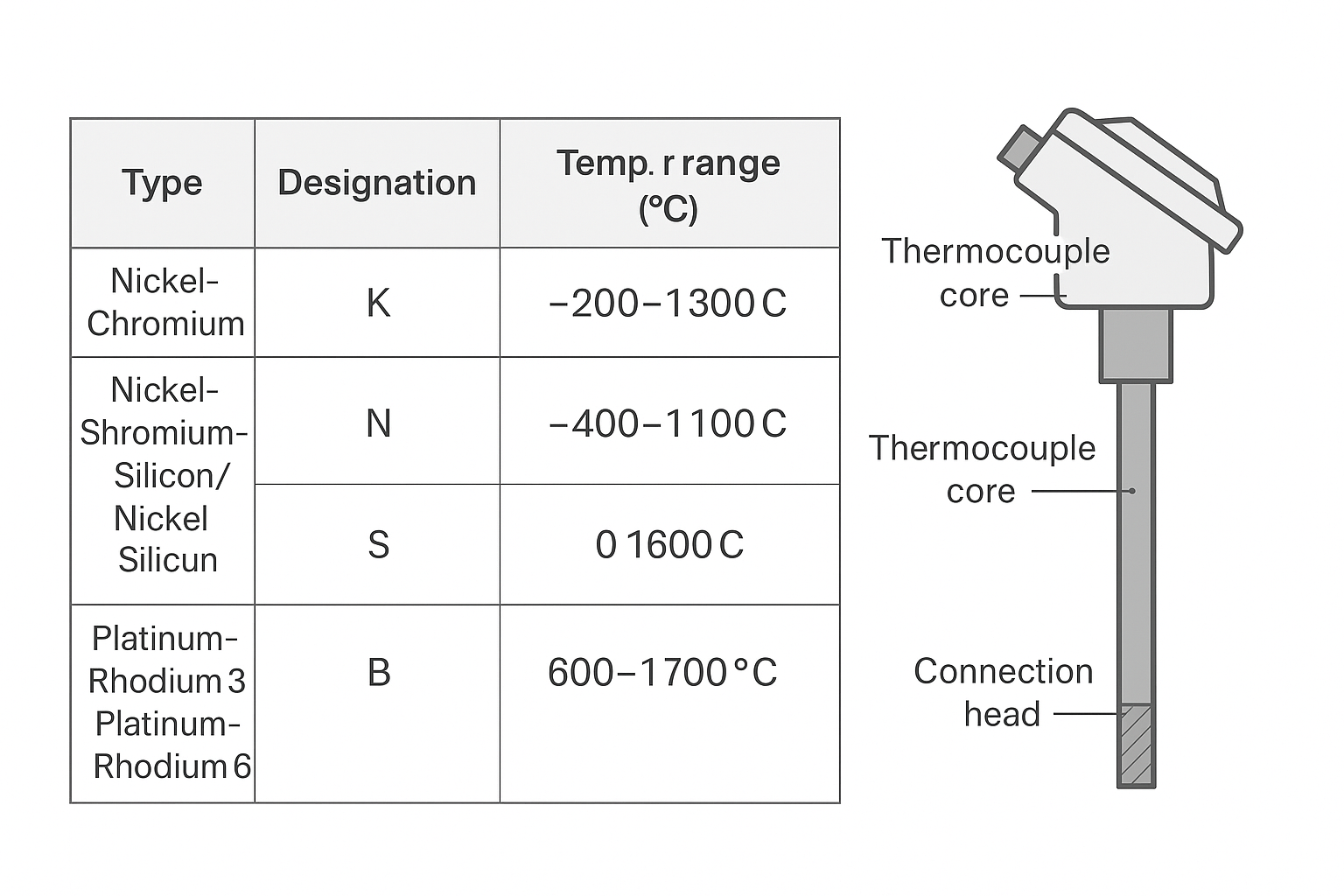

The tungsten-cobalt alloy acts as a protective sheath against abrasive wear and does not directly participate in temperature sensing. Accuracy is dictated by the thermoelectric element inside the sheath. Common types include:

| Type | Designation | Temp. Range (°C) | IEC Accuracy Class | Typical Tolerance |

|---|---|---|---|---|

| Nickel-Chromium / Nickel-Silicon | K | -200~1300 | Class I: -40~1100°C | ±1.5°C or ±0.4% t |

| Class II: -40~1300°C | ±2.5°C or ±0.75% t | |||

| Nickel-Chromium-Silicon / Nickel-Silicon | N | -200~1300 | Class I: -40~1100°C | ±1.5°C or ±0.4% t |

| Platinum-Rhodium 10 / Platinum | S | 0~1600 | Class I: 0~1100°C | ±1°C or ±0.5% t |

| Platinum-Rhodium 30 / Platinum-Rhodium 6 | B | 600~1800 | Class II: 600~1700°C | ±0.25% t |

K/N type: cost-effective, suitable for mid-to-high temperature, accuracy ±1.5~2.5°C.

S/B type: for high-precision and high-temperature calibration, accuracy ±1~3°C.

2. Structural Impact on Accuracy

Sheath thickness: Tungsten-cobalt alloy sheaths are often 3–10 mm thick for durability. This slows thermal response but does not reduce steady-state accuracy.

Thermal conductivity: ~80–120 W/(m·K), faster than ceramic sheaths but slower than thin stainless steel.

3. Installation and Operating Factors

Wear condition: Uneven wear over time may slightly affect heat transfer (<1% error).

Insertion depth: Should reach 1/3–1/2 of the pipe diameter to avoid wall heat loss bias.

EMI: Strong electromagnetic fields require shielded cables and grounding to avoid noise errors.

4. Summary Accuracy Level

K/N core: ±1.5–2.5°C (low temp) or ±0.4–0.75% t (high temp) — suitable for most industrial uses.

S/B core: ±1–3°C — for metallurgy, high-temperature calibration, and precision-critical tasks.

The tungsten-cobalt alloy’s main advantage lies in maintaining accuracy over a long service life in abrasive environments, not in inherently increasing the measurement precision.