Introduction

Submersible level transmitters, also known as hydrostatic level sensors, are widely used for monitoring liquid levels in tanks, wells, reservoirs, and treatment facilities. Whether applied in clean water, wastewater, oil, or corrosive chemicals, proper maintenance is essential to ensure accurate readings and long-term reliability.

In this article, we’ll walk you through key maintenance tips, common issues, and practical troubleshooting methods to help you get the most out of your submersible level sensor.

1. 🧽 Regular Cleaning of the Sensor Probe

Why:

Dirt, sludge, algae, or scale buildup on the probe may cause inaccurate readings.

How:

Rinse the sensor head with clean water.

Use a soft brush or cloth to gently remove deposits.

Avoid using sharp tools or strong acids.

For hard scaling, a diluted vinegar (acetic acid) solution can be used briefly.

Frequency:

Every 1–3 months depending on your application environment.

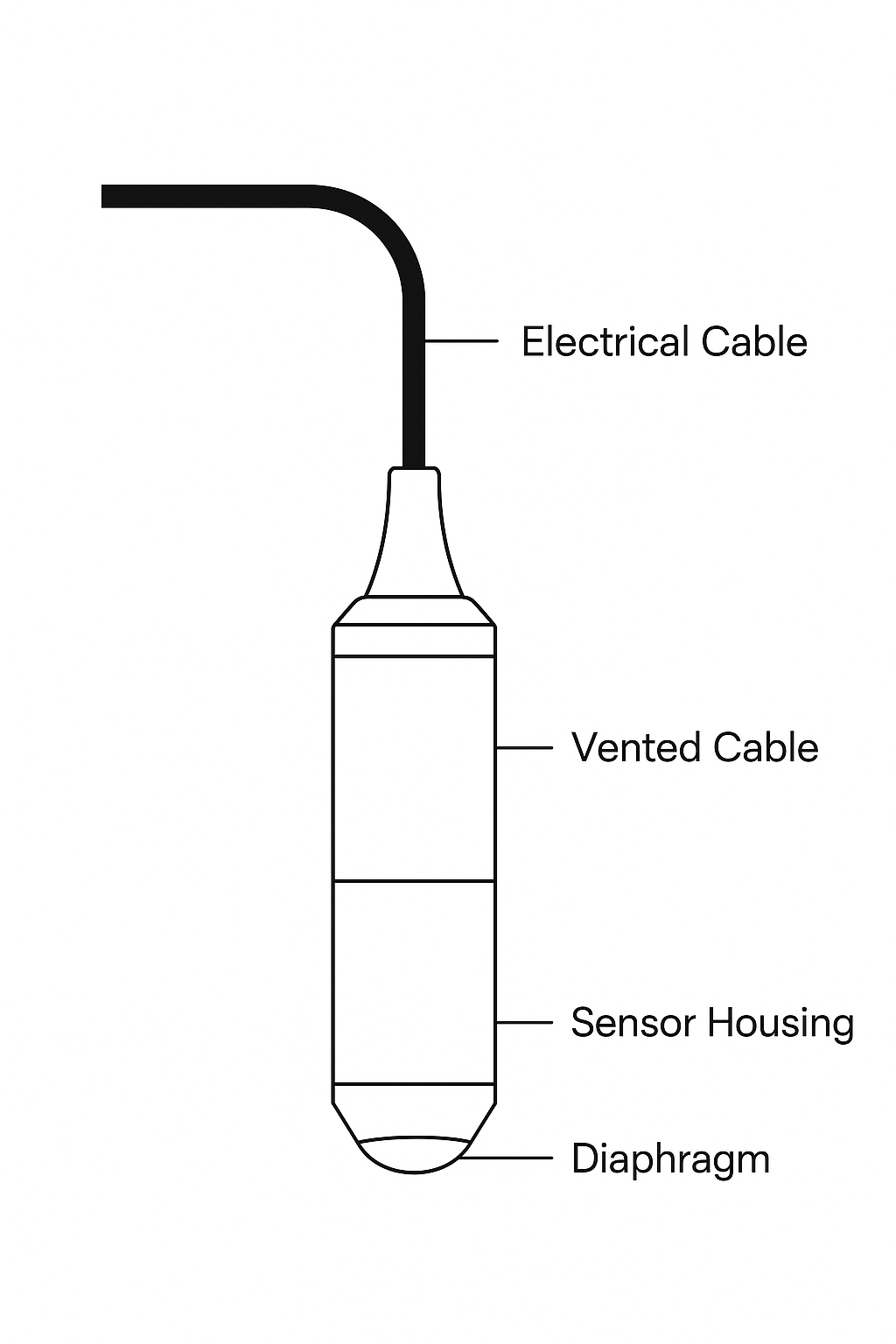

2. 🔌 Check Cable Integrity and Vent Tube

Why:

The cable is not only for electrical signals but may include a built-in vent tube for atmospheric pressure compensation.

What to do:

Check for cracks, abrasions, moisture ingress, or deformation.

Ensure the vent tube is not blocked or kinked.

Avoid bending the cable too tightly or crushing it.

Pro tip:

Use desiccant cartridges or filters at the cable end to prevent moisture from entering the vent tube.

3. 🔧 Periodic Verification and Recalibration

Why:

To ensure continued measurement accuracy over time.

How:

Compare the transmitter readings with a known liquid level (e.g., using a dipstick or sight glass).

If deviation is found, follow the manufacturer’s procedure to recalibrate or return it for factory calibration.

Recommended:

At least once per year, or more frequently in critical applications.

4. ⚡ Ensure Proper Surge and Water Protection

Why:

Outdoor installations are vulnerable to lightning and water ingress.

Actions:

Use surge protectors if lightning exposure is expected.

Make sure all electrical connections and cable joints are properly sealed.

Avoid submerging cable joints unless specified as waterproof.

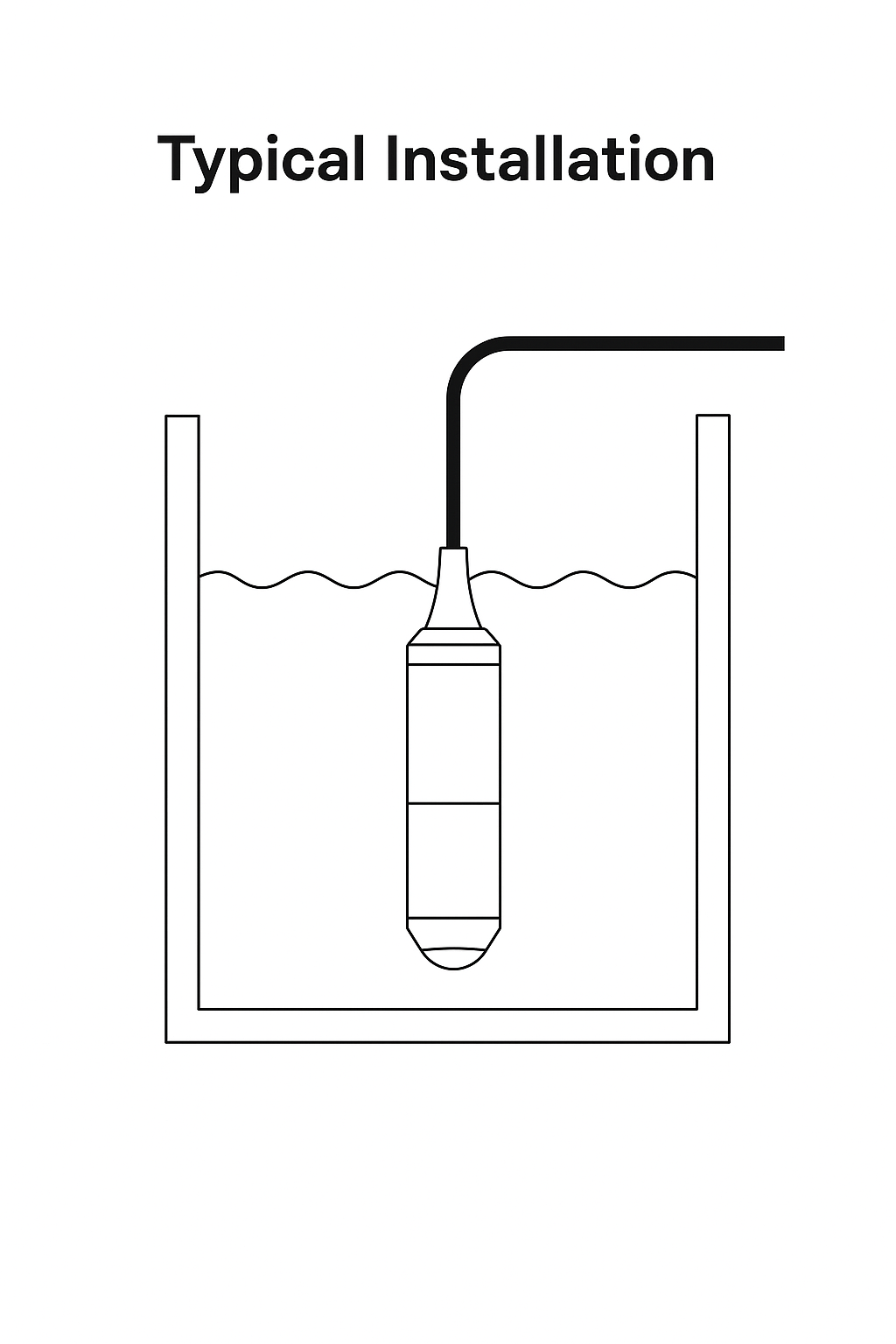

5. 📏 Optimize Installation Conditions

Installation tips:

Install the sensor vertically and keep it away from inlet/outlet turbulence or air bubbles.

In deep wells or tanks, use a protective stilling well or weight to keep the sensor stable.

Ensure that the probe does not touch the tank bottom or float freely in high-flow areas.

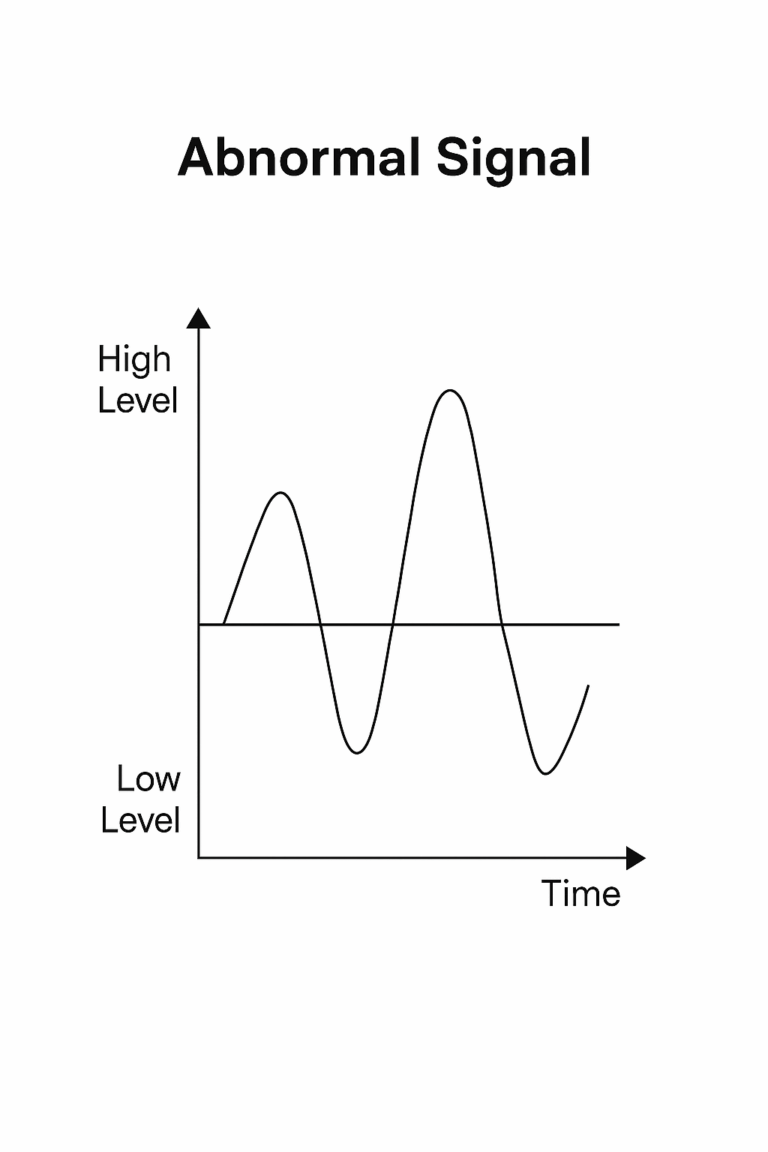

6. 🔍 Monitor for Signal Drift or Anomalies

Symptoms to watch:

Fluctuating or spiking output

Output signal stuck at 0 or max

Obvious offset compared to expected level

Troubleshooting checklist:

Confirm stable power supply (e.g., 24V DC)

Check wiring continuity and polarity

Inspect vent tube for blockages

Clean sensor if fouling is suspected

🛠️ Common Fault Table

| Issue | Possible Cause | Solution |

|---|---|---|

| Output fluctuates | Air bubbles / turbulence | Reposition probe or add stilling tube |

| No signal or 0 output | Broken cable / short circuit | Check wiring or replace probe |

| Signal drifts slowly | Moisture in vent tube | Replace desiccant or dry tube |

| Inaccurate reading | Sensor head fouled or blocked | Clean the sensor head |

✅ Summary & Best Practices

Clean the probe regularly, especially in dirty or corrosive fluids.

Protect the cable and vent tube from damage and water ingress.

Verify and calibrate the sensor annually or as needed.

Use appropriate mounting accessories to avoid physical damage.

Monitor signal behavior and act early to resolve issues.

Need Help Choosing or Maintaining Your Level Sensor?

At Dalian Zero Instrument, we offer tailored solutions for harsh industrial environments. Whether it’s fresh water, chemical media, or slurry applications, our engineers can help you select the right submersible level sensor and provide long-term technical support.

📩 Contact us at for free consultation or maintenance manuals.