Water ingress at wiring terminals is one of the most persistent and damaging issues in outdoor instrumentation and control systems. Studies show that over 30% of equipment failures are caused by moisture penetrating wiring junctions, leading to corroded contacts, insulation aging, short circuits, and signal interruptions.

Now, a new solution has emerged: the next-generation waterproof terminal. With its innovative structure and enhanced sealing technologies, it serves as a protective barrier in humid environments. Let’s explore why water ingress occurs, its consequences, and how the new waterproof terminal solves the issue.

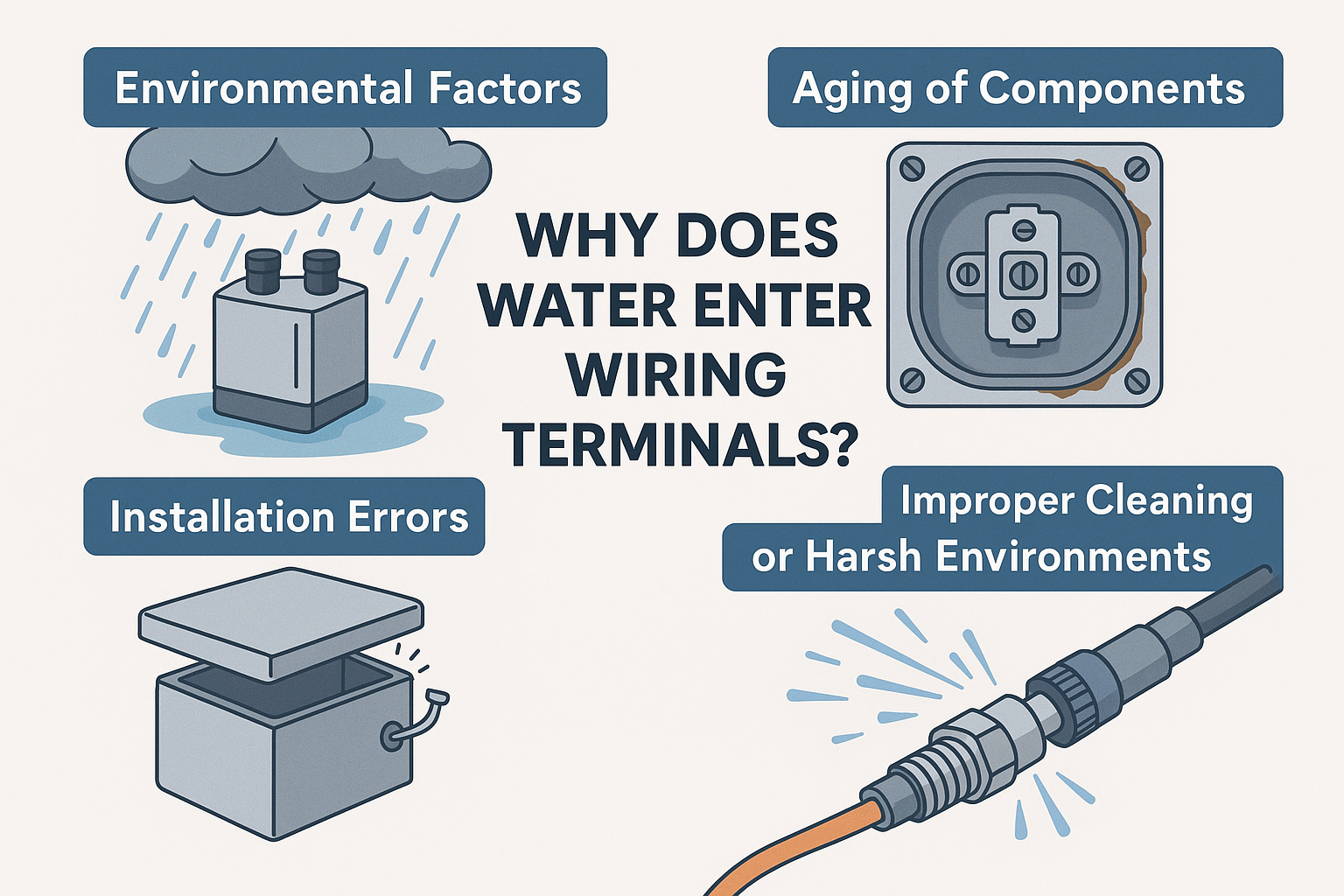

1. Why Does Water Enter Wiring Terminals?

💧 Environmental Factors

Heavy rain and storms exert high-pressure water on enclosures.

If the enclosure has even a tiny gap or degraded seals, water will penetrate.

Equipment installed in low-lying areas may be submerged in water during flooding.

⚙️ Aging of Components

Sealing rings on terminal boxes may deform or crack after long-term use, weakening protection.

Cracks in the enclosure due to corrosion or impact provide entry points for water.

🔧 Installation Errors

Loose or insufficient screws between the cover and body create gaps.

Unused reserved holes without proper sealing become leakage paths.

🚿 Improper Cleaning or Harsh Environments

High-pressure water jets during cleaning may compromise seals.

Long-term exposure to high-humidity or underwater environments accelerates seal degradation.

2. The Solution: Waterproof Terminal Technology

Traditional solutions include improved installation angles, protective enclosures, and reinforced coil-sealing. However, they only mitigate the problem, not eliminate it.

The new-generation waterproof terminal addresses the root cause through structural innovation:

✅ a) Integrated Compression Seal Design

Replaces traditional dual-seal ring structures with a single-piece compression seal.

Achieves excellent waterproof performance with fewer components, simplifying the design and enhancing reliability.

✅ b) Innovative Structure for Comprehensive Sealing

Consists of a terminal head, terminal pin, and O-ring seal.

Terminal head: made of high-temperature resistant engineering plastic (250–300°C).

Terminal pin: conductive core wrapped in rubber for insulation.

O-ring placed precisely in mating area between head and pin to ensure tight sealing.

This design significantly improves installation success rate in field conditions and eliminates the risk of leakage due to improper assembly.

✅ c) Miniaturized but Powerful

Compact form factor (~2cm), suitable for tight spaces in control cabinets or instrument enclosures.

Despite the small size, it integrates sealing and self-tightening mechanisms.

Passes harsh saltwater immersion tests under power-on conditions, proving its industrial-grade durability.

3. Field Applications: From Workshops to Outdoor Projects

🌧️ In Humid Industrial Environments

Locations: damp workshops, underground pump rooms, valve pits.

Risks: insulation failure, coil corrosion, stuck valve spools.

Testing: 7×24-hour immersion in saltwater showed no electrical failure.

🌦️ In Outdoor Installations

Applications: streetlights, monitoring devices in coastal regions.

Performance: survives short-term submersion during heavy rains or typhoons.

Replaces temporary waterproofing solutions like plastic covers or fabric wraps.

Illustration suggestion:

Comparison diagram: traditional vs waterproof terminal structure

Installation scenario: waterproof terminal in underground cabinet

Saltwater testing photo or schematic

4. Summary: Active Protection over Passive Repairs

| Comparison | Traditional Terminal | Waterproof Terminal |

|---|---|---|

| Sealing | Prone to leakage if installed poorly | Reliable sealing through O-ring & compression |

| Maintenance | Frequent replacements | Long service life |

| Installation | Complex with high failure rate | Simple & consistent |

| Cost | Higher long-term cost | Reduced total cost of ownership |

The waterproof terminal provides a robust and reliable solution to one of the most difficult maintenance challenges in industrial automation. It prevents water ingress at the source, reduces failure rates, and supports safe, uninterrupted operation of instrumentation systems.

If your field instruments are frequently exposed to moisture, this may be the ultimate solution you’ve been waiting for.