🔧 Overview

The tungsten-cobalt alloy wear-resistant thermocouple is a specialized temperature sensing device designed for harsh conditions involving intensive abrasion, high temperatures, and particulate erosion. By using a WC-Co (tungsten carbide–cobalt) alloy as the protective sheath or sensing tip, it offers enhanced durability compared to traditional thermocouples.

This document covers the structure, application scenarios, selection guidelines, and usage precautions.

🧩 1. Structure & Key Advantages

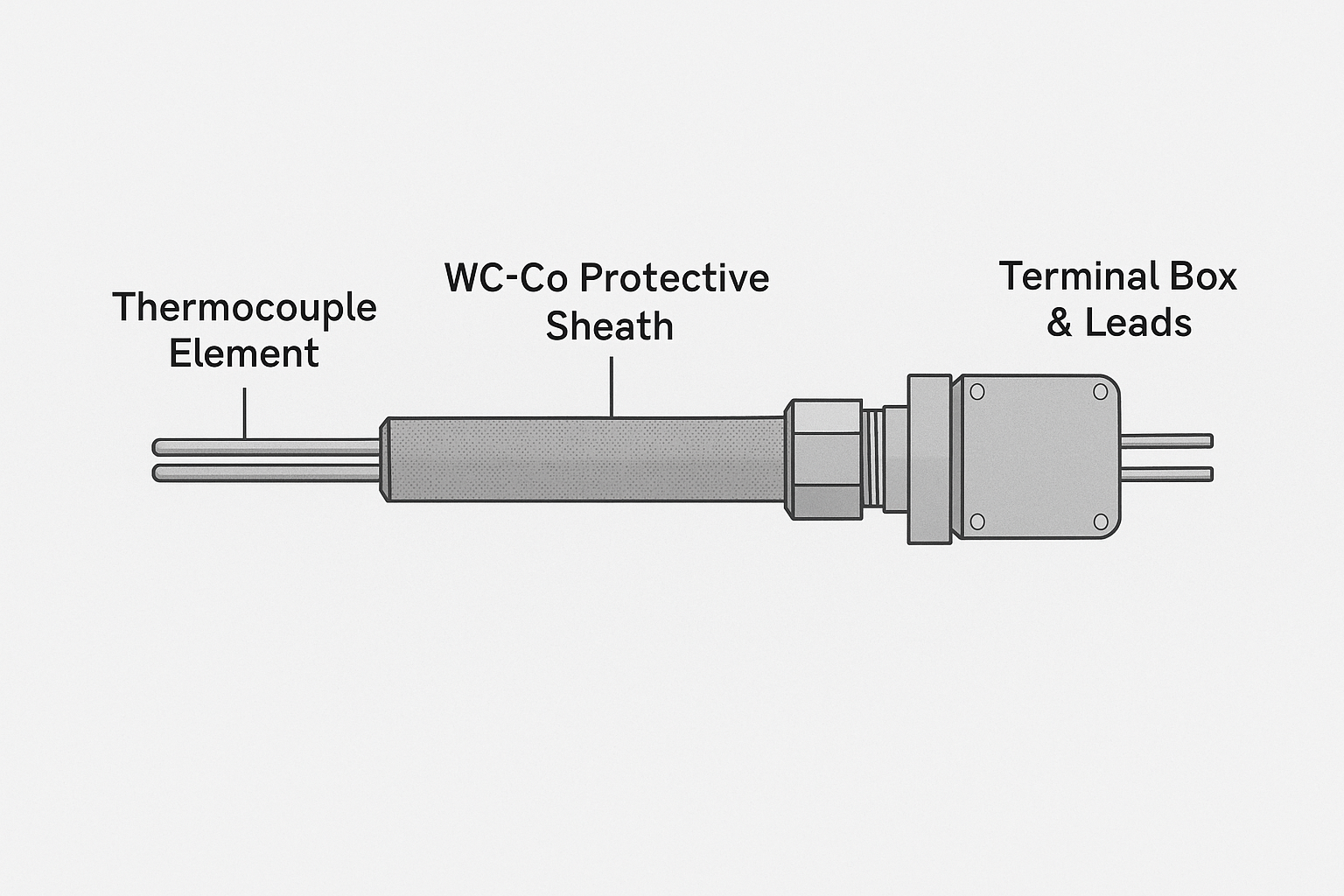

📌 Basic Components

| Component | Description |

|---|---|

| Thermocouple Element | Typically K type (-200~1300°C), N type (better oxidation resistance), or S type (high accuracy and stability). |

| WC-Co Protective Sheath | Made of tungsten carbide (WC) and cobalt (Co), with hardness up to HRC 65~90, offering superior wear resistance. |

| Terminal Box & Leads | Transfers thermoelectric signal to secondary instruments; waterproof and dustproof designs are common. |

💡 Core Advantages

Exceptional Wear Resistance:

Up to 10–50 times more wear-resistant than 316 stainless steel; ideal for abrasive media like coal powder, slag, sand, etc.High Temperature Tolerance:

Suitable for short-term exposure up to 1000~1200°C, depending on the alloy composition.Impact Resistance:

More durable than ceramic tubes in environments with material collisions or vibrations.

🏭 2. Typical Application Scenarios

| Industry | Application Area | Medium |

|---|---|---|

| Power Generation | Boiler outlets, pulverized coal pipelines, fluidized bed | Coal dust, fly ash, flue gas |

| Metallurgy | Blast furnace hot stoves, sintering heads/tails, rotary kilns | Iron ore, sinter, hot slag |

| Building Materials | Cement kilns, glass melting furnaces | Raw cement, glass fragments, dust |

| Mining & Chemicals | Crushing systems, fluidized bed reactors | Ore particles, catalyst powder |

📌 These applications feature high-speed abrasive particle flow and high temperatures.

⚙️ 3. Selection Guidelines

📍 Thermocouple Type

| Type | Temperature Range | Features | Notes |

|---|---|---|---|

| K | -200 ~ 1300°C | Economical, widely used | Common for general use |

| N | 0 ~ 1200°C | Better oxidation resistance | Suitable for higher reliability |

| S | 0 ~ 1600°C | High precision, stable | High cost |

📍 WC-Co Alloy Grade

| Grade | Co Content | Features | Temperature Suitability |

|---|---|---|---|

| YG8 / YG10 | 6–10% | Higher hardness, better wear resistance | ≤800°C |

| YT Series | 12–15% | Better thermal shock resistance, may include TiC | ≤1200°C |

📍 Protective Tube Structure

| Structure | Description | Suitability |

|---|---|---|

| Integrated | One-piece tube and sensing tip | Best for heavy abrasion |

| Composite | WC-Co tip welded with stainless or alloy steel tube | Cost-effective, replaceable |

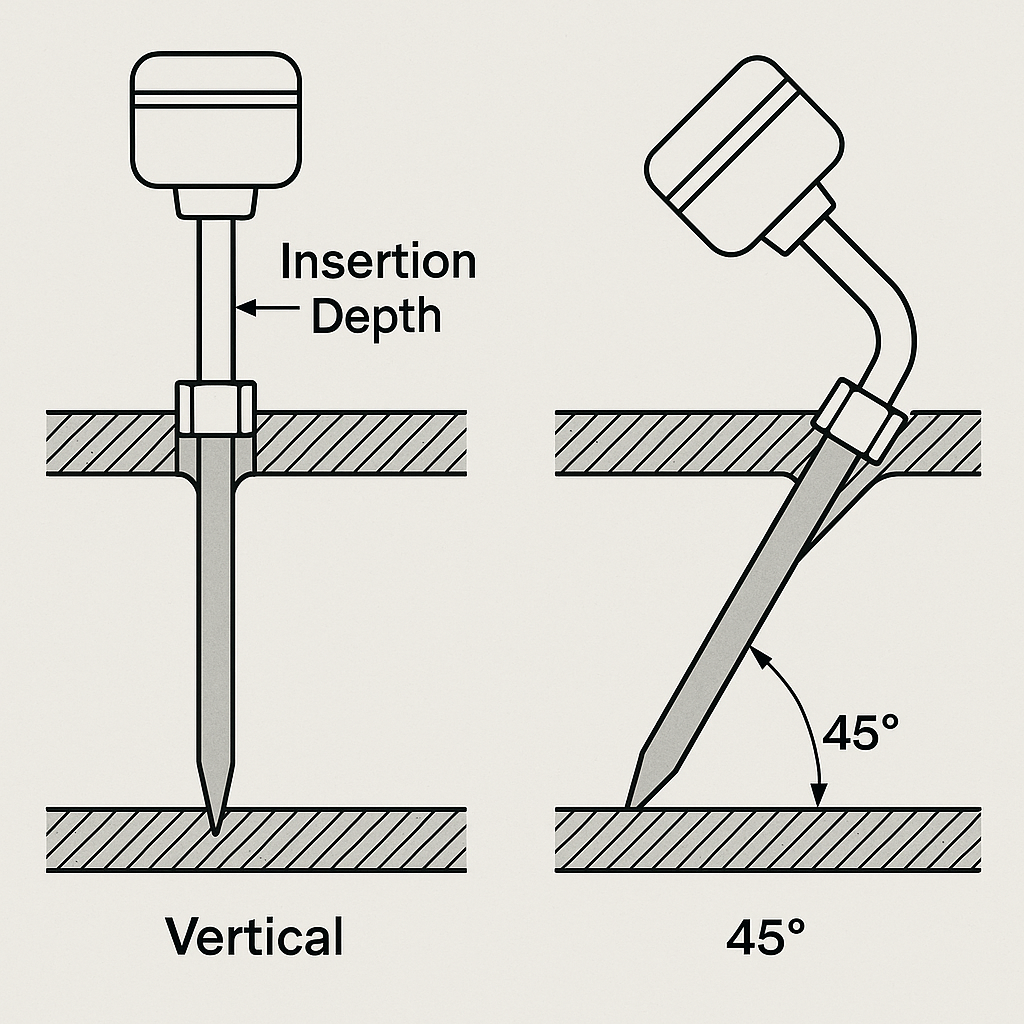

📍 Insertion Depth & Mounting Angle

Insert 20–50mm beyond the inner wall of the pipeline or furnace.

Avoid overlong insertions to prevent vibration-induced damage.

Mounting Angle: Vertical or inclined at 45° to reduce direct impact.

Install a wear-deflecting baffle if necessary.

⚠️ 4. Usage Precautions

Avoid Overheating

WC-Co alloys oxidize and soften above 1200°C. Long-term use should stay below rated limits (typically ≤1000°C).Prevent Thermal Shock

Avoid frequent transitions between hot and cold environments to prevent cracking.Routine Wear Inspection

Check the tube wall thickness every 3–6 months. Replace if wear exceeds 1/3 of the original thickness.Gas Atmosphere Compatibility

In reducing atmospheres (e.g., containing H₂ or CO), WC-Co may undergo decarburization. Consider using inert gas shielding or ceramic-metal hybrid sheaths.

✅ Summary

Tungsten-cobalt alloy thermocouples offer a robust solution for high-wear, high-temperature environments where traditional thermocouples fail prematurely. By selecting the right thermocouple type, alloy grade, and installation method, users can greatly extend service life and improve measurement reliability. This ensures stable process control and enhanced equipment safety in challenging industrial applications.