Back pressure, as the name implies, refers to the static pressure that exists on the downstream side of a flow system. It represents a form of resistance against the direction of fluid flow and plays a crucial role in various industrial processes involving liquids or gases.

This article explains what back pressure is, its key roles in system stability and equipment protection, methods of adjustment, and essential safety considerations during configuration and tuning.

1. What Is Back Pressure?

Back pressure is the resistance or reverse pressure exerted by downstream components such as valves, pipe bends, or pressure regulators in a closed or semi-closed fluid system.

It is commonly encountered in:

Hydraulic and pneumatic circuits

Chemical processing pipelines

Injection molding machines

Flow measurement applications

Pharmaceutical, food, and water treatment industries

Proper control of back pressure is essential to maintain system stability, prevent cavitation, ensure accurate flow measurements, and protect mechanical components from surge damage.

2. Key Functions of Back Pressure

2.1 Pressure Stabilization

In hydraulic or pneumatic systems, back pressure can act as a buffer against sudden pressure drops, helping avoid vaporization, cavitation, or the formation of gas pockets.

📌 Example: Installing a back pressure valve at the outlet of a hydraulic pump minimizes pressure fluctuation.

2.2 Flow Regulation

Back pressure influences the rate of flow. By adjusting valve openings, you can increase or decrease downstream resistance.

📌 Example: In mass flow metering systems for custody transfer, partially closing the downstream valve creates controlled back pressure to improve accuracy.

2.3 Equipment Protection

High-speed fluid flow can cause mechanical shock or water hammer effects. Back pressure can moderate this by reducing velocity or releasing pressure gradually.

📌 Example: In centrifugal pumps, a back pressure valve helps prevent sudden pressure release during shutdown, protecting pipelines.

2.4 Process Quality Control

In plastic injection molding, back pressure helps regulate molten resin flow, ensuring uniform mixing and reducing defects like air bubbles or shrinkage.

📌 Example: Controlled back pressure enhances dimensional stability in molded parts.

3. How to Adjust Back Pressure

3.1 Matching System Requirements

Select appropriate back pressure levels based on system operating pressure, medium characteristics, and flow demands.

Hydraulic systems often set back pressure at 10–20% of working pressure.

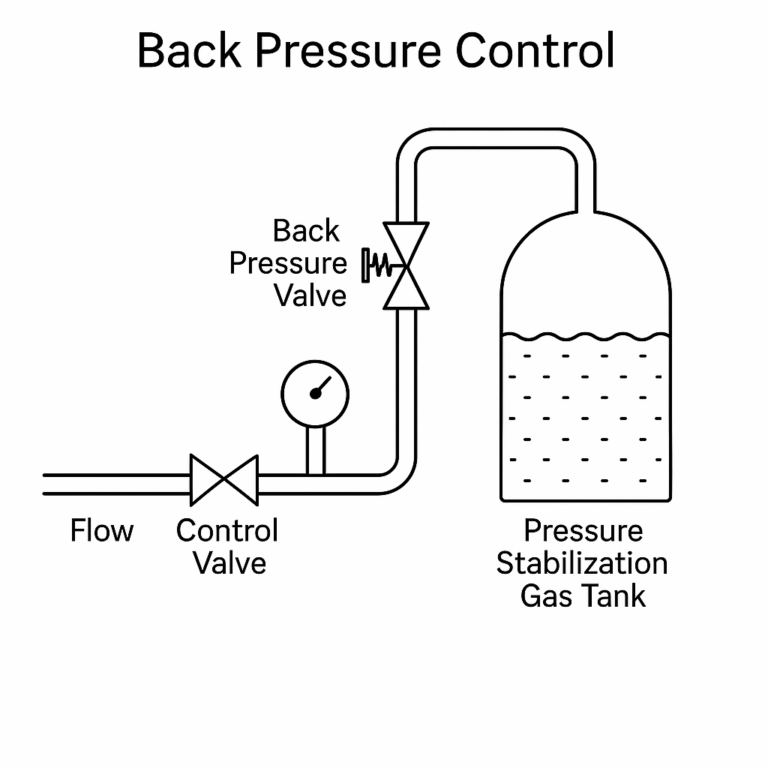

3.2 Valve Adjustment

Use back pressure valves or control valves—either manual or automated—to fine-tune flow resistance.

Smaller valve openings increase resistance and raise back pressure.

3.3 Pipeline Optimization

Modify pipeline length, reduce the number of elbows, or use pipe reducers to alter pressure drop characteristics.

Example: In exhaust system modifications, increasing length or reducing diameter can raise back pressure appropriately.

3.4 Use of Pressure-Stabilizing Devices

Install accumulators, pressure compensators, or spring-loaded valves to dynamically maintain pressure balance.

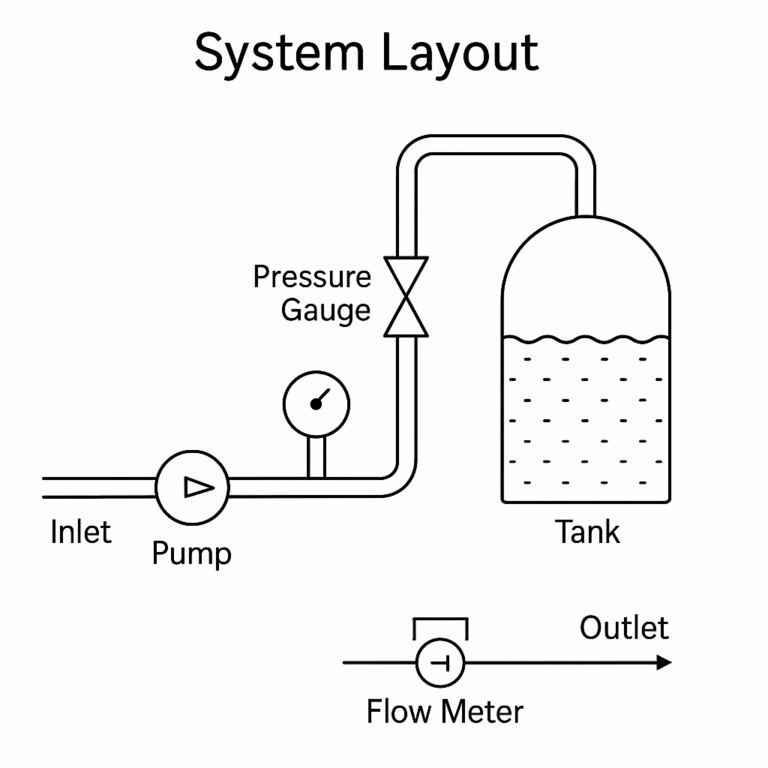

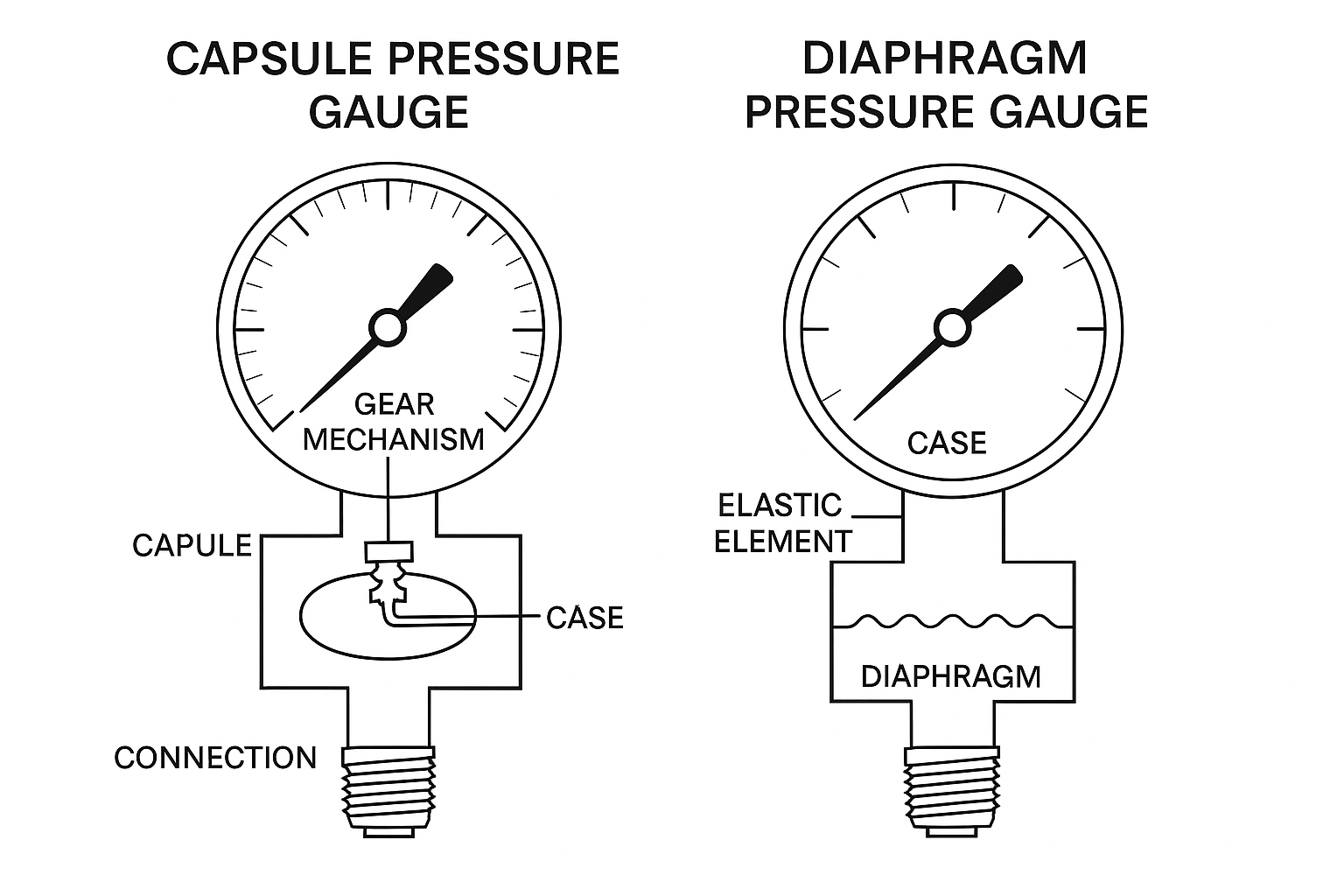

3.5 Real-Time Monitoring

Use pressure gauges or transmitters to verify actual back pressure. Instruments or software can analyze system performance and confirm adjustments.

4. Key Considerations When Adjusting Back Pressure

❗ Avoid Excessive or Insufficient Pressure

Too high: increases energy consumption, reduces efficiency, may overload components.

Too low: can lead to cavitation, unstable flow, or insufficient process control.

⚙️ Gradual Adjustment

Make small incremental changes and observe system response after each adjustment.

Sudden changes can cause shock or trigger faults.

🎯 System-Specific Logic

Different systems (e.g., fluid transport vs. reaction vessels) require different back pressure strategies.

Hydraulic: tuned for pressure retention

Gas: tuned for compressibility and expansion

Flow measurement: tuned for signal stability

5. Conclusion

Back pressure is more than just a resistance—it is a vital control parameter for maintaining stable, efficient, and safe industrial processes. Properly adjusting and managing back pressure helps:

Stabilize system behavior

Improve flow accuracy

Protect pumps, sensors, and pipelines

Enhance process output and product quality

By integrating intelligent design, appropriate valves, and real-time monitoring, engineers can unlock the full value of back pressure control in their systems.