1. Introduction

In the chemical industry, a process package—often referred to as a technology package or engineering design package—is the foundational set of documents and specifications for designing, constructing, and operating a chemical production unit. It plays a central role in ensuring safety, operability, and efficiency throughout the plant lifecycle.

The development of a process package is a complex, multidisciplinary task involving professionals from process engineering, chemical analysis, instrumentation and control, safety and environmental engineering, and other domains. This document outlines the typical components, scope, and depth of a standard chemical process package.

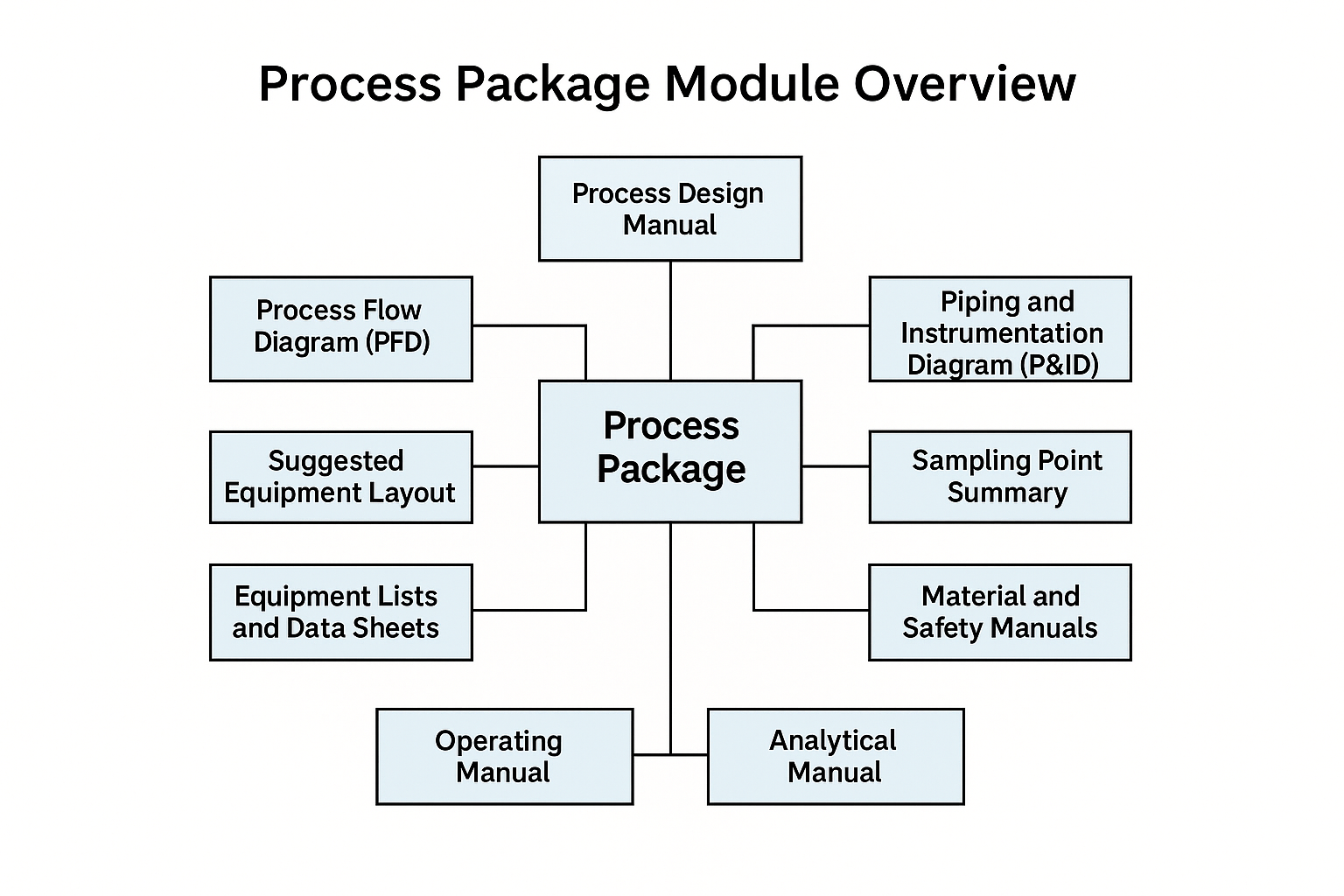

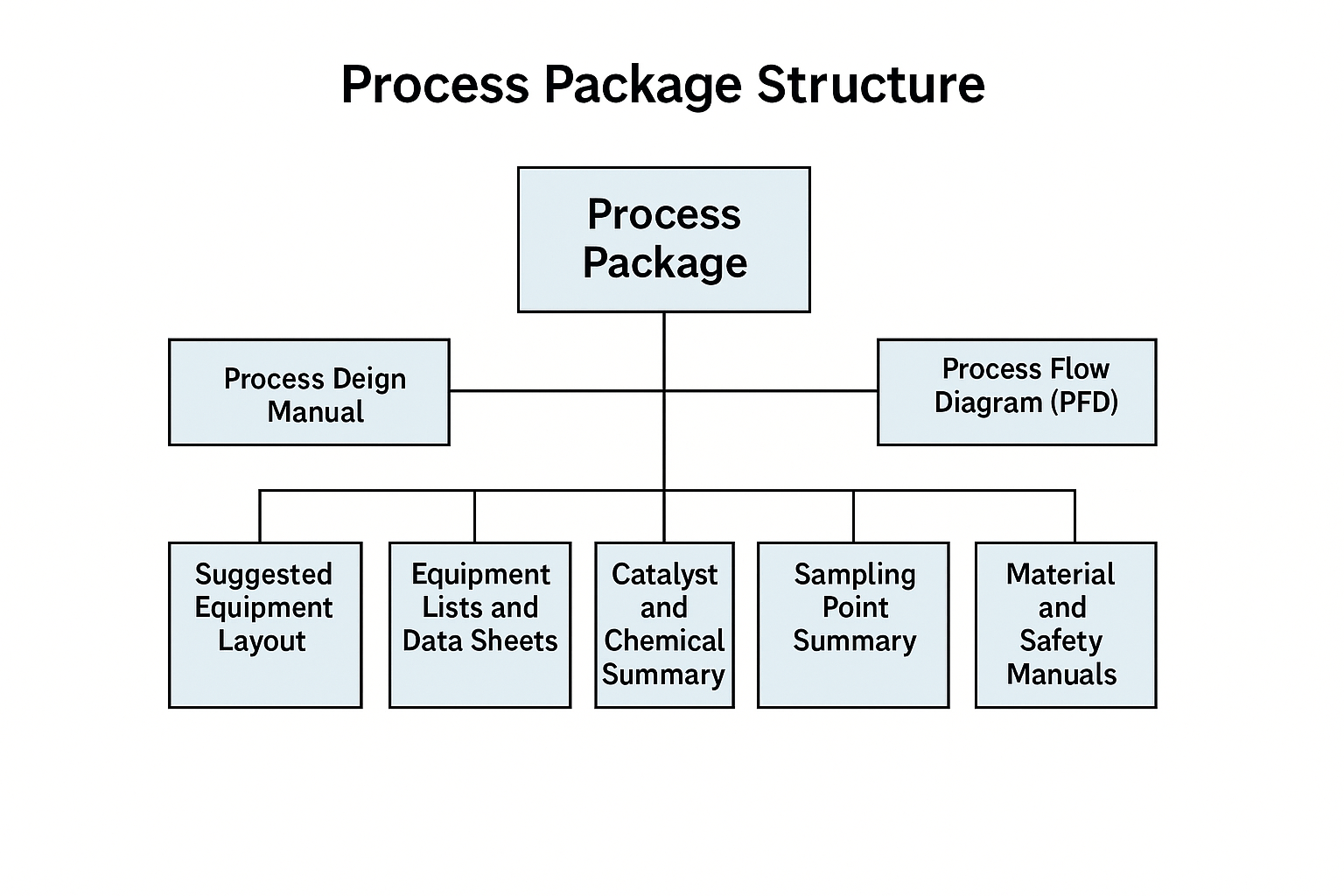

2. Standard Components of a Process Package

A complete process package generally includes the following documents and data:

Process Design Manual

Process Flow Diagram (PFD)

Piping and Instrumentation Diagram (P&ID)

Suggested Equipment Layout

Equipment List and Data Sheets

Catalyst and Chemical Summary

Sampling Point Summary

Material and Safety Manuals

Operating Manual

Physical Property Data

Supporting Calculations and Design Bases

Each section provides critical information for downstream engineering design, construction, commissioning, and operation.

3. Process Design Manual

The process design manual is a comprehensive document that describes the design basis, process philosophy, and key operating parameters. It usually includes:

3.1 Overview

Process selection and technology features

Design capacity (e.g., tons/year or m³/year), operating hours per year

Plant operating philosophy (e.g., 5 shifts, 3 operations)

Process unit breakdown (by section or subsystem)

3.2 Environmental Impact

List of equipment generating wastewater, waste gas, and solid waste

Quantitative estimates of emissions and disposal methods

Preliminary plans for waste treatment and resource recovery

3.3 Design Basis

Feedstock and chemical specifications

Utility specifications (steam, water, electricity, air)

3.4 Process Description

Process principles and reactions (including main and side reactions)

Catalyst types and specifications

Section-by-section or system-based process descriptions (e.g., reactor, distillation column, compressor)

3.5 Operating Conditions and Controls

Key process conditions: temperature, pressure, flowrate, composition

Control indicators and target values

Product specification and yield expectations (guaranteed and expected)

Raw material and utility consumption figures

3.6 Equipment Selection Philosophy

Justification for key equipment types (e.g., heat exchangers, reactors, pumps)

Notes on materials of construction and design considerations

Control and safety interlock system logic

4. Process Flow Diagrams (PFDs)

The PFD provides a high-level visual representation of the material flow and energy exchange within the process. It typically includes:

Major equipment symbols and tag numbers

Stream numbers with flow direction

Operating conditions (flowrate, temperature, pressure, composition)

Utility interfaces

Material balance tables

PFDs serve as a foundation for developing P&IDs and process simulations.

5. Piping and Instrumentation Diagrams (P&IDs)

P&IDs provide detailed information on the piping, instrumentation, and control systems. They include:

Equipment symbols and interconnections

Pipe specifications and line numbers

Instrumentation, valves, and control loops

Safety systems and interlocks

Utility piping and tie-in points

These diagrams are essential for construction, commissioning, and maintenance planning.

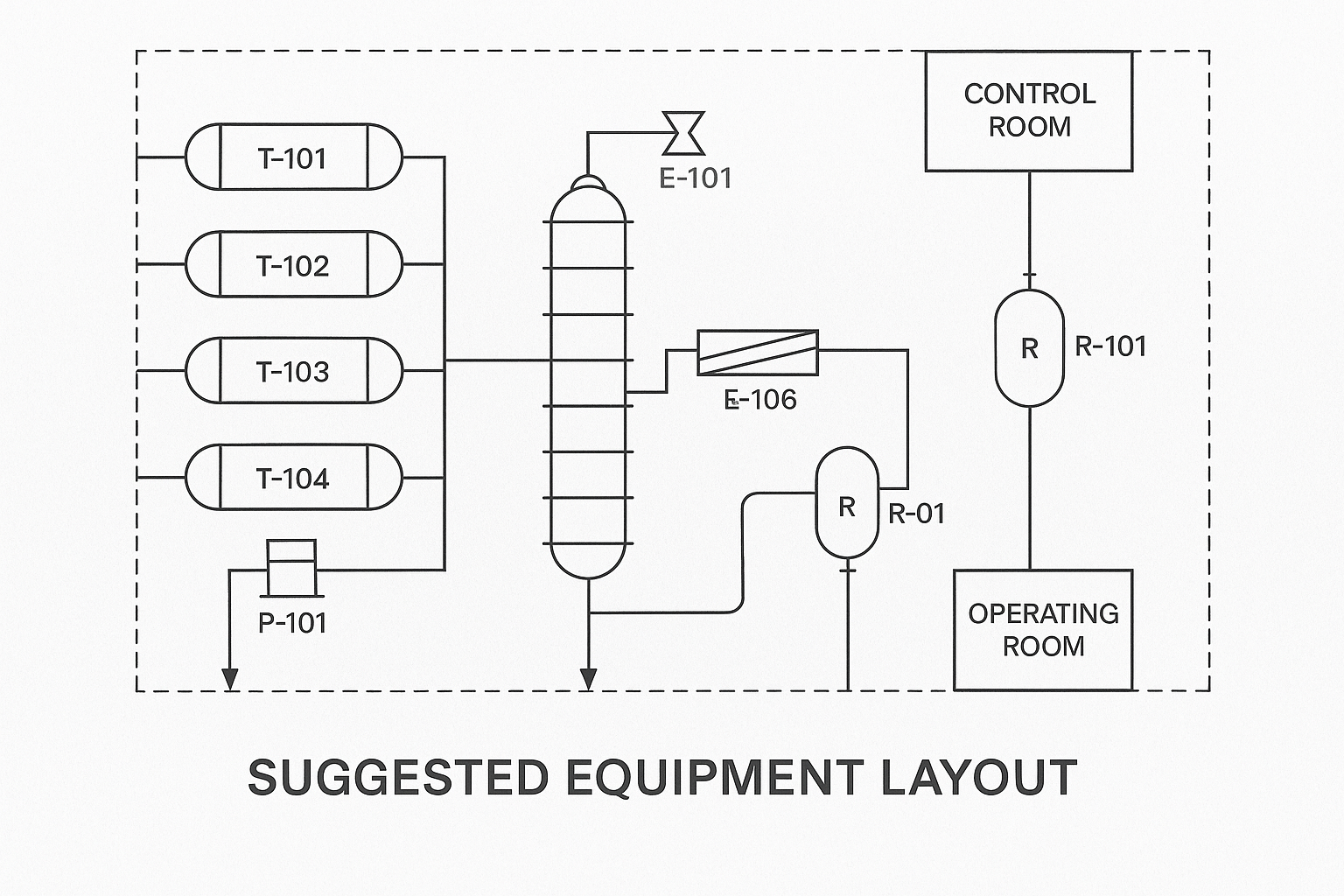

6. Suggested Equipment Layout

The layout drawing offers a reference for equipment positioning and space allocation. While preliminary in nature, it should cover:

Building and structure outlines with reference dimensions

Relative positions and elevations of major equipment

Special height requirements for gravity-driven systems or safety

Locations of control rooms and operating stations

This layout helps ensure proper access, maintenance space, and safety zoning.

7. Equipment Lists and Data Sheets

These documents provide structured technical information for procurement and design:

Equipment List: A master list with tag numbers, names, types, and quantities

Data Sheets: Detailed operating parameters, design conditions, materials of construction, mechanical details, and reference sketches

They are prepared for major equipment such as:

Reactors

Columns

Heat exchangers

Pumps and compressors

Storage tanks

Filters

8. Catalyst and Chemical Summary

For catalytic or reactive processes, a table is provided listing:

Catalyst name, grade, and supplier

Loading quantity and replacement schedule

Required auxiliary chemicals (e.g., neutralizers, inhibitors)

Safety and storage requirements

9. Sampling Point Summary

This summary helps design the analytical control system and laboratory interface. It includes:

Sampling point location and tag

Type of sample (gas, liquid, slurry)

Analysis items and frequency

Sample collection and handling method

Safety precautions

This ensures traceability and effective process monitoring.

10. Safety, Health, and Environmental Manual

The safety manual addresses risks related to flammability, toxicity, explosions, and occupational exposure.

Contents include:

Process hazard analysis

Fire and explosion prevention measures

Toxicity data of raw materials and products

Protective equipment recommendations (e.g., respirators, eye washers)

Emergency response requirements (e.g., venting systems, alarms)

A well-prepared safety manual significantly reduces risk during commissioning and operation.

11. Operating Manual

Typically prepared by the licensor or engineering contractor after design completion, the operating manual covers:

Process philosophy and control logic

Startup, shutdown, and emergency operation procedures

Key operating parameters per system (reactor, column, etc.)

Checklists for inspection and pre-commissioning

Equipment lubrication, flushing, purging, and calibration steps

It ensures consistent, safe operation and facilitates staff training.

12. Analytical Manual

This manual outlines methods and responsibilities for process analysis. It includes:

Laboratory workflow and organizational responsibilities

Sampling design principles and frequency

Sample preparation and storage procedures

Analytical methods for feedstock, intermediates, and products

Instrument calibration and quality control guidance

Clear analytical procedures are critical for quality assurance and process optimization.

13. Physical Property Data and Calculations

A comprehensive process package often includes a property data booklet and associated calculation sheets:

Thermophysical properties (density, viscosity, heat capacity)

Vapor-liquid equilibrium data

Utility demand calculations

Pressure drop and line sizing

Equipment rating and simulation results

This technical foundation supports further engineering design (basic/detailed), simulation, and optimization.

14. Quality Control and Documentation Standards

Process package documents must adhere to internal quality standards and international codes. Key principles include:

Use of standardized templates

Revision control

Document numbering system

Multidisciplinary review and sign-off

Consistency ensures all parties (engineering, construction, and operators) can rely on the information provided.

15. Conclusion

A well-developed process package is not merely a set of drawings—it’s a comprehensive technical solution that enables safe, efficient, and economically viable chemical production. From process flows to safety strategies, each component ensures that the plant can be built and operated with confidence.

As chemical production becomes more sophisticated, the importance of standardized, detailed, and accessible process packages will only increase. Whether for internal design, technology licensing, or third-party review, a strong process package is the cornerstone of chemical engineering excellence.