Anti-condensation ultrasonic level sensors are designed to perform reliably in humid, high-moisture, and high-temperature-difference environments. Their ability to prevent signal disruption caused by condensation makes them ideal for various industrial, agricultural, municipal, and logistics applications.

1. Industrial Process Applications in Humid Conditions

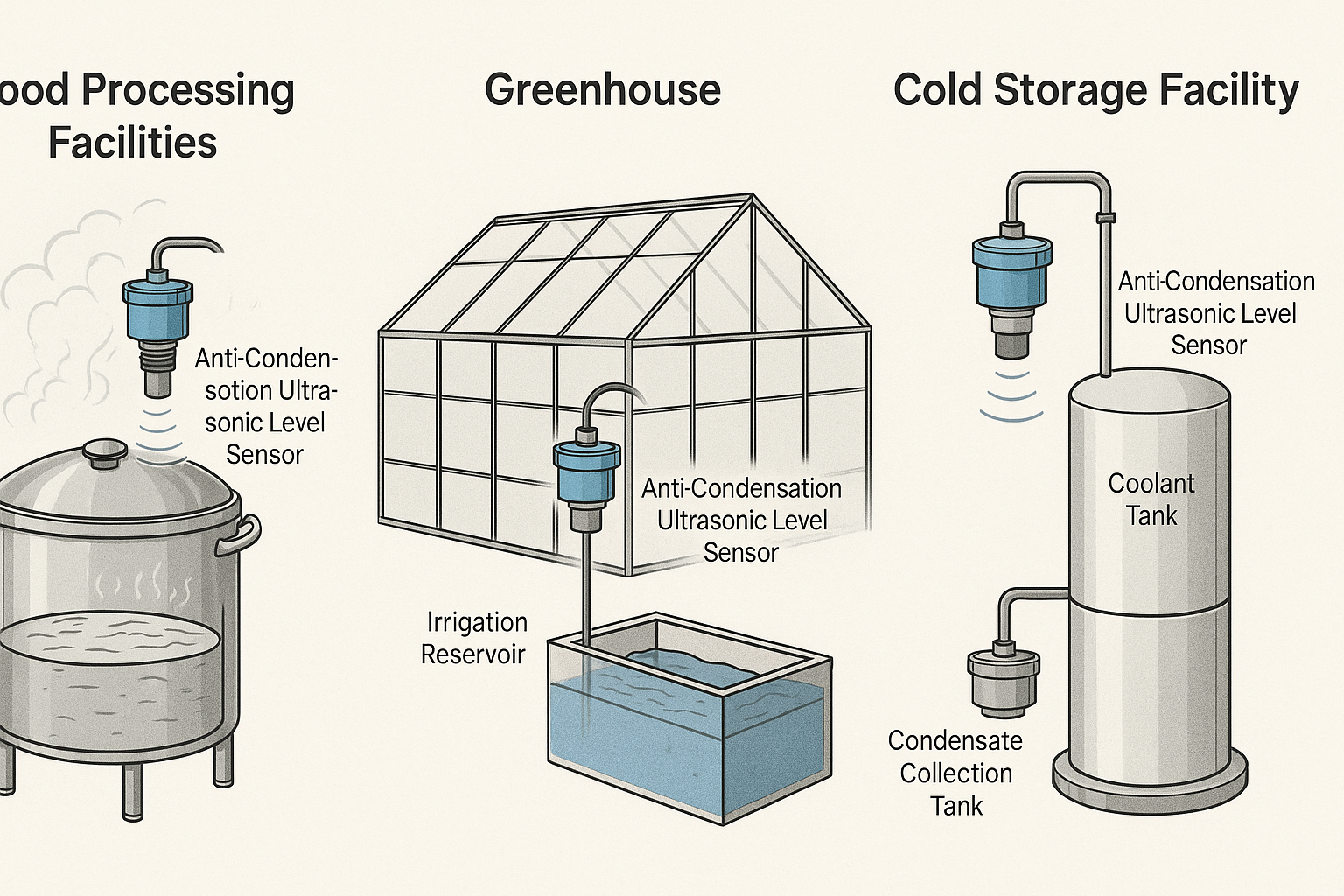

● Food Processing Facilities

In processes such as can sterilization, sauce boiling, and fruit/vegetable washing, large volumes of steam lead to extremely high humidity and temperature fluctuations. Standard ultrasonic sensors often suffer from condensation, causing inaccurate measurements. Anti-condensation sensors ensure reliable level detection in cooking kettles, washing tanks, and ingredient storage vessels, safeguarding production stability.

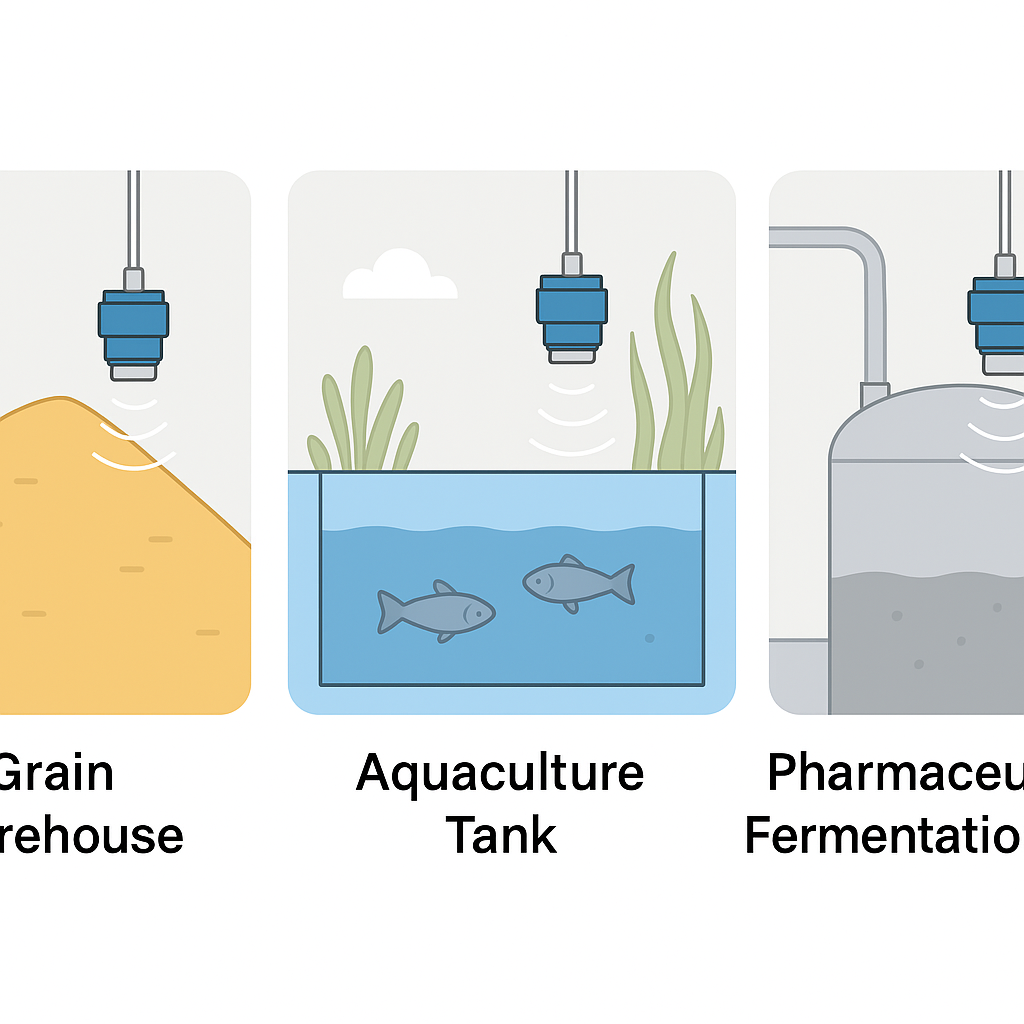

● Pharmaceutical Fermentation Rooms

Fermentation requires stable humidity and temperature. The area around fermenters is typically moist and may contain corrosive gases. Anti-condensation sensors—especially those with corrosion-resistant materials—can accurately monitor liquid levels in fermenters and support precise process control.

● Chemical Reactors

Many chemical reactions generate vapor and occur in high-humidity environments. Accurate level monitoring in reactors is critical for safety and quality control. Anti-condensation ultrasonic sensors deliver reliable data unaffected by moisture-induced measurement drift.

2. Agricultural and Water Management Applications

● Greenhouses

Greenhouses maintain high humidity to promote crop growth. With significant day-night temperature differences, condensation easily forms on devices. Anti-condensation sensors monitor water tanks and irrigation reservoirs to ensure accurate water supply in challenging environments.

● Aquaculture Tanks

Aquaculture environments—especially during summer or in poorly ventilated facilities—are prone to high humidity. Water level control is essential for fish and shrimp farming. These sensors maintain stable level readings and support timely water adjustments.

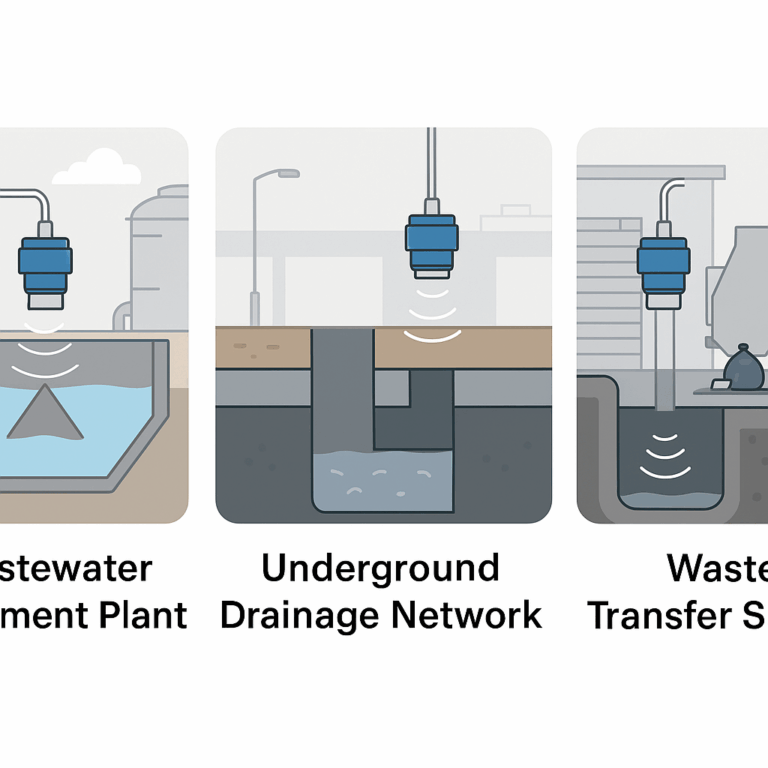

● Wastewater Treatment Plants

Humidity is high in grit chambers, equalization basins, and sedimentation tanks. Vapors and corrosive gases are common. Anti-condensation sensors provide accurate level monitoring, improving the stability and efficiency of treatment processes.

3. Warehousing and Cold Chain Logistics

● Cold Storage Facilities

Low internal temperatures and warmer external environments lead to condensation or even icing on sensor surfaces. Heated anti-condensation probes prevent surface moisture accumulation, ensuring accurate level readings in coolant tanks or condensate collection units.

● Grain Warehouses

Poor ventilation in grain storage can lead to elevated humidity. Moisture from the grain bed may evaporate and condense nearby. Anti-condensation sensors are suitable for monitoring water supply tanks and drainage pits to preserve grain quality.

4. Municipal and Public Infrastructure

● Underground Drainage Networks and Sump Pits

These locations are typically dark, damp, and prone to water vapor. Standard probes often suffer from inaccurate readings due to condensation. Anti-condensation ultrasonic sensors ensure accurate level monitoring, aiding flood prevention and fault diagnostics.

● Waste Transfer Stations

Leachate generated during waste handling creates a highly humid and corrosive environment. These sensors are ideal for monitoring leachate collection pits, enabling timely removal and preventing overflow and pollution.

Conclusion and Selection Guide

Anti-condensation ultrasonic level sensors are vital in high-humidity or temperature-variable environments. Their primary value lies in ensuring stable and accurate level measurement by preventing condensation interference.

Key selection considerations:

| Factor | Recommendation |

|---|---|

| Humidity & Condensation Risk | Consider probes with built-in heating or surface hydrophobic coatings |

| Corrosive Atmospheres | Choose models with PTFE-coated or stainless steel housings |

| Temperature Variations | Use sensors with temperature compensation or active heating elements |

| Mounting Environment | Verify sealing grade (e.g., IP68), anti-freeze performance |

By matching the right anti-condensation technology—such as heating circuits, modified materials, or hydrophobic design—to your specific environment, you can maximize sensor performance and extend service life.