Introduction

In industries such as petrochemicals, energy, and logistics, storage tanks serve as critical infrastructure. The spacing between tanks is not just a matter of preliminary or detailed design—it directly impacts site safety, operational efficiency, and future scalability.

Although tank spacing may appear straightforward, it is in fact a highly systematic engineering decision. This article explores how to determine tank spacing based on national codes, industry standards, and engineering practices, taking into account tank type, stored media, and layout arrangements.

1. Why Is Tank Spacing So Important?

Proper spacing between tanks is essential for safe production and efficient plant operations. Its significance includes:

Operational Accessibility

Adequate space for routine inspections, pipe maintenance, and level measurements.Personnel Safety

Avoids compounded risks from working in confined, high-temperature, or flammable areas.Maintenance Feasibility

Insufficient space may hinder lifting operations or make maintenance impractical.Emergency Response

Proper spacing allows for rapid deployment of fire trucks, sprinklers, and evacuation.Irreversibility of Layout

Once built, tank layouts are difficult to alter through administrative controls alone.Risk Propagation

Poor spacing can result in a domino effect, where one tank failure triggers adjacent incidents.

Conclusion: Tank spacing must consider structure, volume, media hazards, fire protection, and construction needs—ensuring site-specific, safe planning.

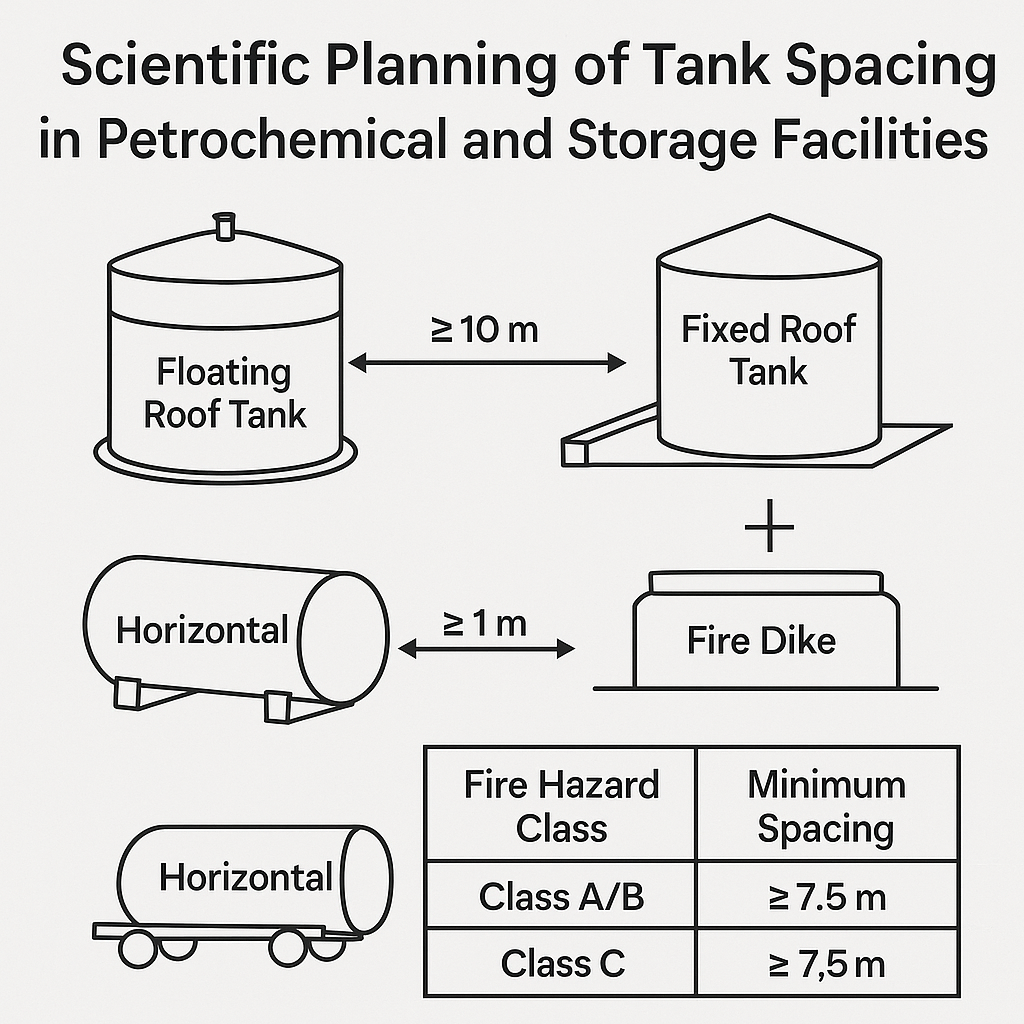

2. Spacing Standards for Different Tank Types

2.1 Floating Roof Tanks

Application: High-volatility liquids like gasoline or naphtha

Features: Open-top design reduces evaporation but is susceptible to lightning and fire

Recommended Spacing:

≥ 1/2 of the larger tank’s diameter, and ≥ 10 meters

≥ 20 meters suggested in practice for safe lifting and fire separation

2.2 Fixed Roof Tanks

Application: Medium- and low-volatility liquids (e.g., diesel, lubricants)

Structure: Sealed roof with good evaporation control

Spacing Guidelines:

For Class A/B liquids: same as floating roof tanks

For Class C liquids: ≥ D/6, and not less than 5 meters

With internal floating roof: follow floating tank standards

2.3 Horizontal Tanks

Application: Small-to-medium storage (e.g., fuel stations)

Structure: Space-efficient layout with simplified maintenance

Spacing Guidelines:

≥ 1 meter within same tank group

≥ 1/2 tank length between groups

Consider wind orientation, ventilation, leakage prevention, and drainage foundation

Note: Floating roof tanks (internal or external) must not be placed too closely due to fire risk.

2.4 Fixed Roof Tanks – Based on Volume and Media Class

Spacing must be adjusted based on tank volume and flammability class. See table below:

| Fire Hazard Class | Tank Volume (m³) | Minimum Spacing |

|---|---|---|

| Class A/B (flash point < 28°C) | Small / Medium / Large | Refer to standard GB50074 |

| Class C (flash point > 60°C) | Varies | Can be reduced appropriately |

2.5 Multi-Row Layouts

When tanks are arranged in multiple rows, both longitudinal and lateral spacing must comply with relevant standards to ensure access and fire separation.

2.6 Distance to Fire Dikes

Fire dikes prevent liquid leakage and fire spread. Their spacing from tanks must comply with design codes, while also integrating with:

Rainwater drainage

Emergency containment pools

Wastewater collection systems

This prevents secondary hazards from leaks or spills.

2.7 Special Media Tanks (e.g., Cryogenic Tanks)

Cryogenic tanks for LOX, LIN, LAR, etc., pose risks like cold burns, explosions, and high-pressure vaporization.

Spacing Requirements:

≥ 2 meters minimum between tanks

Must include protective spacing from pipe racks, cable trays, and electrical equipment

Anti-condensation and fireproofing measures required

3. Design Principles: Balancing Safety and Practicality

Codes offer minimum spacing rules, but actual design must aim higher:

Safety First: Prevent fire, explosion, and leakage risks

Operational Convenience: Enable lifting, painting, inspection, and walking access

Fire Protection Integration: Leave room for sprinklers, foam systems, fire lanes

Future Flexibility: Plan for potential expansions or new media connections

Multi-Disciplinary Coordination: Align with structural, piping, electrical, and fire protection disciplines

4. Conclusion

Tank spacing is not only a compliance issue—it fundamentally determines a plant’s long-term operational safety. Improper layout risks cannot easily be corrected once the facility is built.

To achieve “safe, operable, and expandable” tank layouts, designers must:

Comply with spacing codes

Ensure practicality for operations and maintenance

Reserve space for future adjustments and capacity upgrades

Only through holistic planning and early-stage foresight can each storage tank operate both safely and efficiently.