Introduction

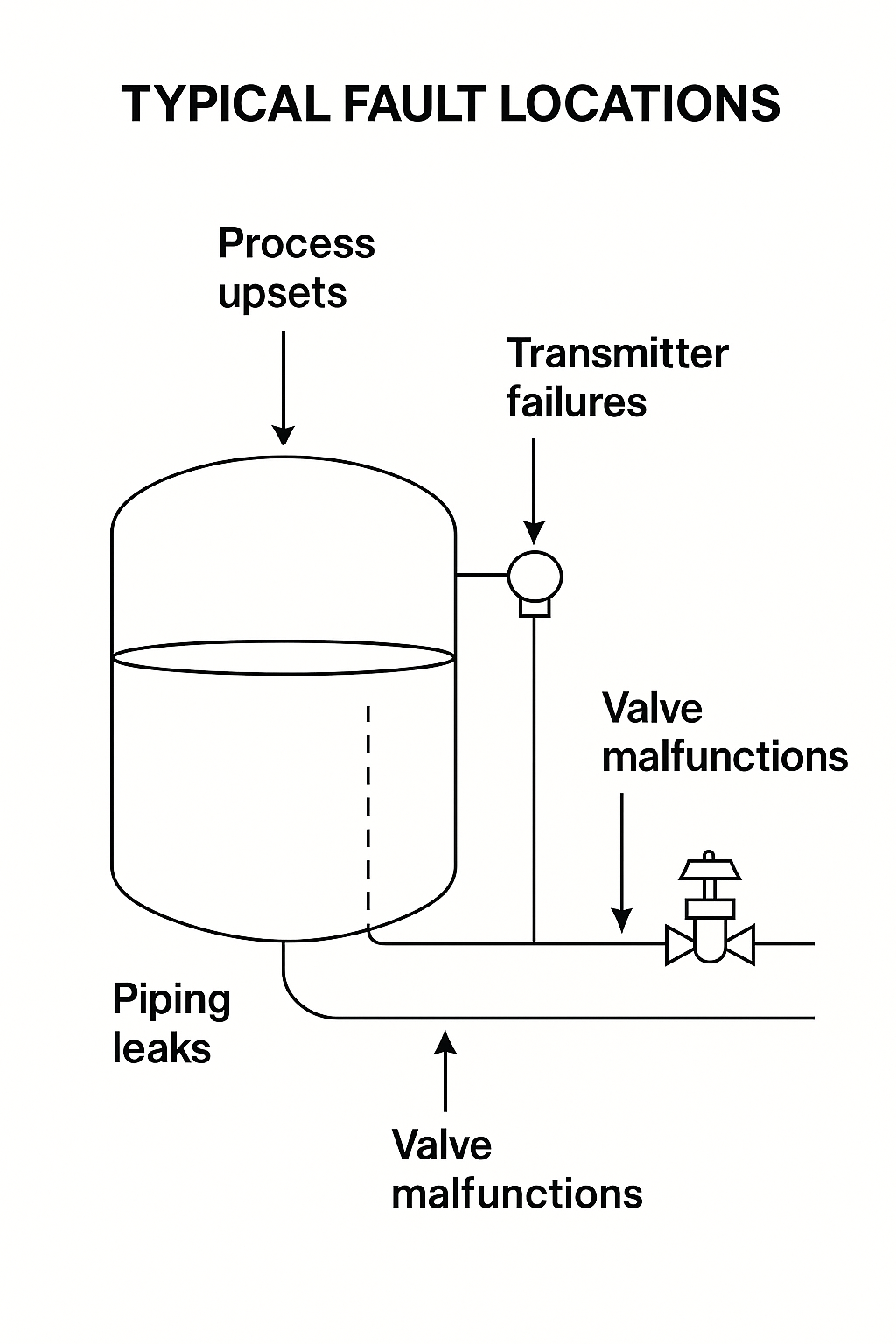

In industrial processes, instrumentation failures can lead to production interruptions, false alarms, or even safety hazards. However, many failures are misdiagnosed due to neglecting critical contextual factors such as process conditions or environmental influences. This article presents a three-step diagnostic method that combines process analysis with instrument characteristics and field conditions to help engineers quickly and accurately identify root causes.

Step 1: Diagnose Based on Process Conditions

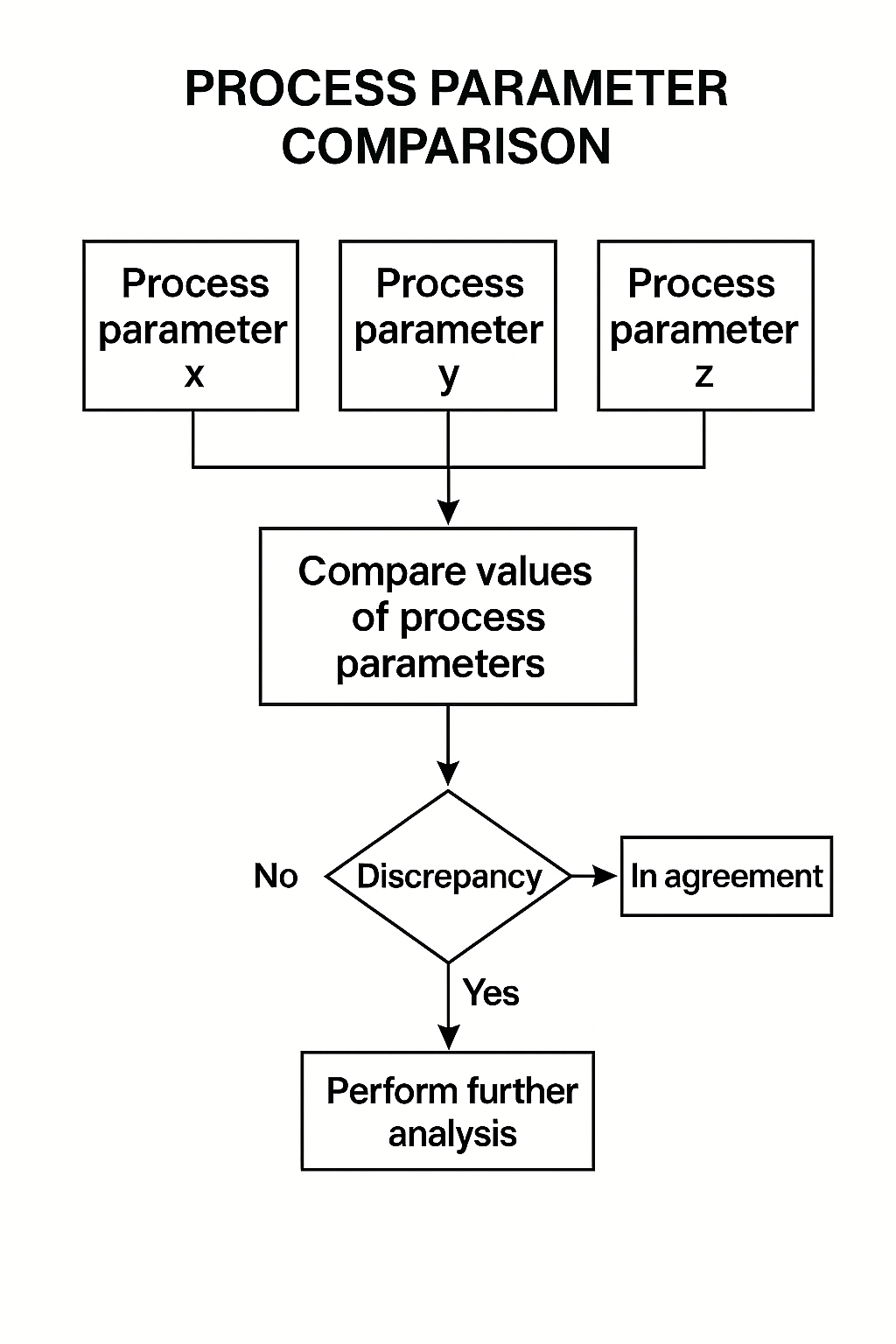

(1) Confirm the Process Operating Status

Stable vs. Abnormal Conditions:

First, check if flow, pressure, and temperature values are within normal ranges. If process values are abnormal (e.g., a sudden drop in flow rate), the issue may stem from the process itself, not the instrument.Cross-Reference Instrument Data:

Example: If a flowmeter reading is abnormal, compare upstream/downstream pressure, temperature, and valve opening to determine if the issue is related to process fluctuation or the instrument itself.

(2) Analyze How Process Variations Affect Instrumentation

Media changes (e.g., aerated liquid, increased particulates) can cause reading deviations.

Pressure/temperature beyond the measuring range can damage sensors.

Pipeline vibration, corrosion, or scaling may affect signal stability (e.g., plugged impulse lines in pressure transmitters).

(3) Review Recent Operational Changes

Have there been recent valve adjustments, equipment starts/stops, or parameter modifications?

Example: If a control valve’s position changes, it may affect the flow reading without being an instrument malfunction.

Step 2: Diagnose Based on Instrument Characteristics

(1) Understand How the Instrument Works

| Instrument Type | Common Failure Points | Typical Symptoms |

|---|---|---|

| Pressure Transmitter | Plugged impulse lines, diaphragm damage | No change in reading, erratic signal |

| Flowmeter | Electrode fouling, liner wear, empty pipe | Zero or fluctuating readings |

| Temperature Sensor | Broken thermocouple, poor wiring connections | Abnormal readings (e.g., -200°C) |

(2) Check Output Signals

4–20mA Loop Check:

Use a multimeter to confirm current output.0mA = possible disconnection

20mA = possible short circuit

HART Communication (for smart devices):

Retrieve diagnostic messages like “Sensor Fault” or “Over Range.”

(3) Review Historical Trends

Sudden jumps: May indicate sensor failure.

Slow drift: Could suggest aging, fouling, or environmental changes.

(4) Investigate Environmental Influences

Electrical interference (e.g., nearby VFDs causing signal noise)

Mechanical vibration (causing loose wiring or sensor damage)

High temperature/humidity (damaging electronics)

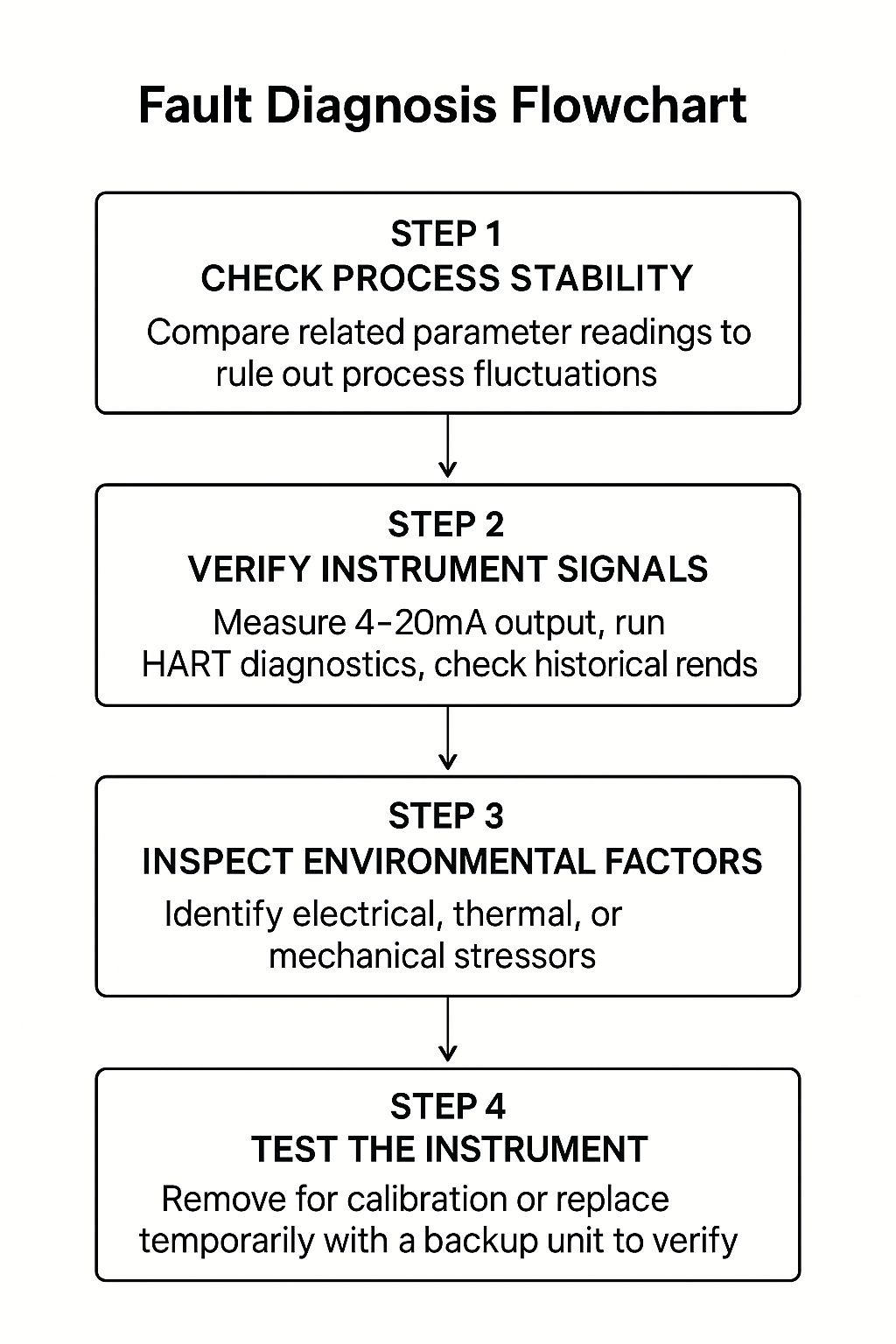

Step 3: Full Diagnostic Flowchart

Check Process Stability

Compare related parameter readings to rule out process anomalies.Verify Instrument Signals

Measure 4-20mA output, run HART diagnostics, and check historical trends.Inspect Environmental Factors

Identify electrical, thermal, or mechanical stressors.Test the Instrument

Remove for calibration or replace temporarily with a backup unit to verify.

Case Studies

✅ Case 1: Flowmeter Reading Zero, Process Stable

Possible Causes:

Electrode fouling due to solid particles in the medium

Empty pipe condition (no liquid inside the pipe)

Solution:

Check medium condition

Clean electrodes or reposition installation

✅ Case 2: Fluctuating Pressure Transmitter Signal

Possible Cause:

Water blockage in impulse lines during gas measurement

Solution:

Drain condensate or install drain valves

Key Takeaways

Instrument failure ≠ immediate replacement

Always assess process conditions first to avoid misdiagnosis.Understand vulnerabilities:

Pressure transmitters → sensitive to clogging

Flowmeters → sensitive to empty pipes

Use data & diagnostics:

Combine historical trends and signal testing to pinpoint root causes.

✅ Applicable Industries:

Chemical, petrochemical, pharmaceutical, power generation, and other process industries.