Introduction

In industrial automation, the choice of signal transmission is critical to the reliability and stability of the control system. Among the various methods available, the 4-20mA current signal has become the de facto standard. But why is 4-20mA preferred over alternatives like 0-20mA or 0-10V?

This article explores the technical, practical, and safety reasons behind the widespread use of 4-20mA signals in industrial environments. Through real-world examples and engineering analysis, we’ll clarify why 4-20mA is more than just a convention — it’s an engineering necessity.

1. Background: Signal Transmission in Automation

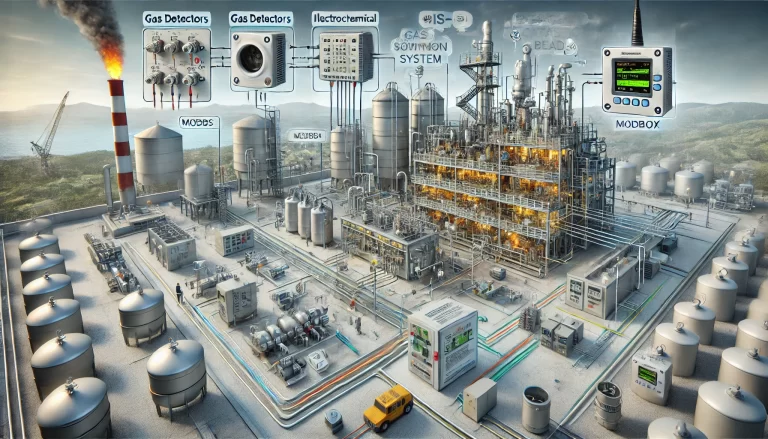

Sensors used in industrial automation — such as those for level, pressure, temperature, and flow — convert physical parameters into electrical signals. These signals are transmitted to control systems like PLCs or DCSs for further processing.

Common analog signal types include:

Current: 4-20mA, 0-20mA

Voltage: 0-10V, 1-5V

So why has 4-20mA become the “golden standard”? Let’s explore.

2. Why 4-20mA?

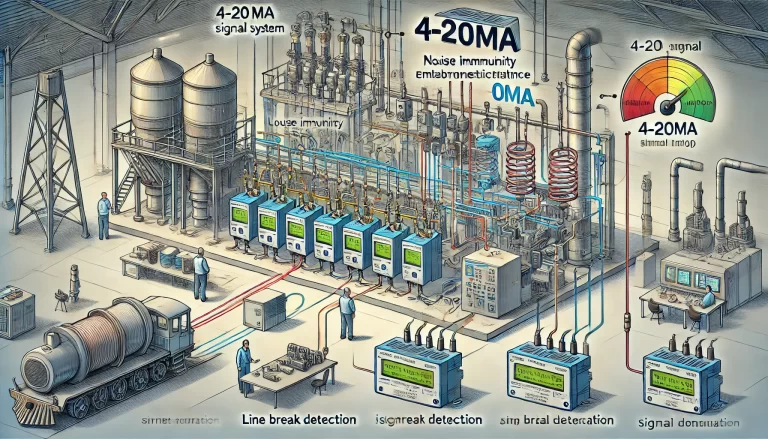

2.1 Live Zero: Built-in Fault Detection

If a 0mA signal is used to indicate the minimum measured value (e.g., 0°C), it becomes impossible to distinguish between a true measurement and a line break. Both cases would show 0mA.

By contrast, 4-20mA introduces a concept called “live zero”:

4mA represents the minimum valid measurement

<3.6mA typically indicates a fault (open circuit, short, or failure)

20.5mA may indicate over-range or sensor failure

This approach enables the system to detect faults automatically. For example, in a chemical plant, a sudden 0mA reading would trigger an alarm to inspect wiring, rather than misinterpreting it as a low temperature.

2.2 Strong Noise Immunity: Reliable Over Long Distances

Industrial environments are full of electromagnetic interference from motors, VFDs, and other equipment. Voltage signals (e.g., 0-10V) are susceptible to:

Electromagnetic noise

Voltage drop over long cable runs

However, current signals remain stable because the current in a closed loop is unaffected by resistance or cable length, as long as the power supply voltage is sufficient (I = V/R).

In large factories with cable lengths exceeding 1 km, a 4-20mA loop ensures reliable transmission, while a voltage signal could degrade significantly.

2.3 Two-Wire Power Supply: Simplified Wiring

Many transmitters (e.g., pressure or temperature) use a two-wire loop where the same two conductors provide both:

Power (typically 24VDC)

Signal (4-20mA)

This reduces wiring complexity and is especially advantageous in:

Remote installations

Hazardous areas

2.4 Low Power Consumption: Safe for Hazardous Areas

At 24VDC and 20mA, the maximum power consumption is only 0.48W — low enough to meet intrinsic safety requirements in explosive environments such as:

Oil refineries

Chemical plants

Underground mines

Voltage-based systems often require higher power levels, increasing the risk of spark generation.

3. Why Not 0-20mA or 0-10V?

3.1 Limitations of 0-20mA

At 0mA, it’s impossible to distinguish whether:

The process variable is at the lower limit

There is a signal fault (e.g., wire break)

This lack of clarity can lead to delayed maintenance or incorrect system responses.

3.2 Limitations of 0-10V

Susceptible to noise: Especially over long distances in noisy industrial environments

Voltage drop: Affects measurement accuracy

Requires separate power lines: No loop-powered option like 4-20mA, leading to higher installation cost and complexity

4. Comparison Table

| Feature | 4-20mA | 0-20mA | 0-10V |

|---|---|---|---|

| Fault detection (Live Zero) | ✅ Yes | ❌ No | ❌ No |

| Noise immunity | ✅ High | ✅ High | ❌ Low |

| Long-distance reliability | ✅ Excellent | ✅ Excellent | ❌ Poor |

| Loop-powered (2-wire) | ✅ Supported | ✅ Supported | ❌ Not supported |

| Suitable for hazardous areas | ✅ Yes (low power) | ✅ Yes (low power) | ❌ Limited |

5. Historical Perspective

The 4-20mA standard didn’t arise by chance. In earlier pneumatic systems, 3-15 psi signals were used — also representing a 1:5 ratio. The 4-20mA range preserved this scaling and helped engineers transition from pneumatic to electronic control systems.

Decades of engineering practice have proven 4-20mA to be reliable, cost-effective, and suitable for virtually all process industries.

6. Conclusion

The 4-20mA current loop remains a foundational element in industrial signal transmission due to its:

Built-in fault detection

Strong resistance to interference

Simplified two-wire wiring

Low power consumption and explosion safety

Its advantages are not merely theoretical — they’re the result of decades of real-world engineering success.

If you’re building or upgrading an automation system, understanding the reasons behind the 4-20mA standard is key to making informed, reliable, and safe design decisions.