In industries where liquid storage plays a vital role—such as oil & gas, petrochemicals, and bulk terminals—the accurate and reliable monitoring of tank contents is not just a best practice, it’s a necessity. This is where Tank Gauging Systems (TGS) come into play.

What Is a Tank Gauging System?

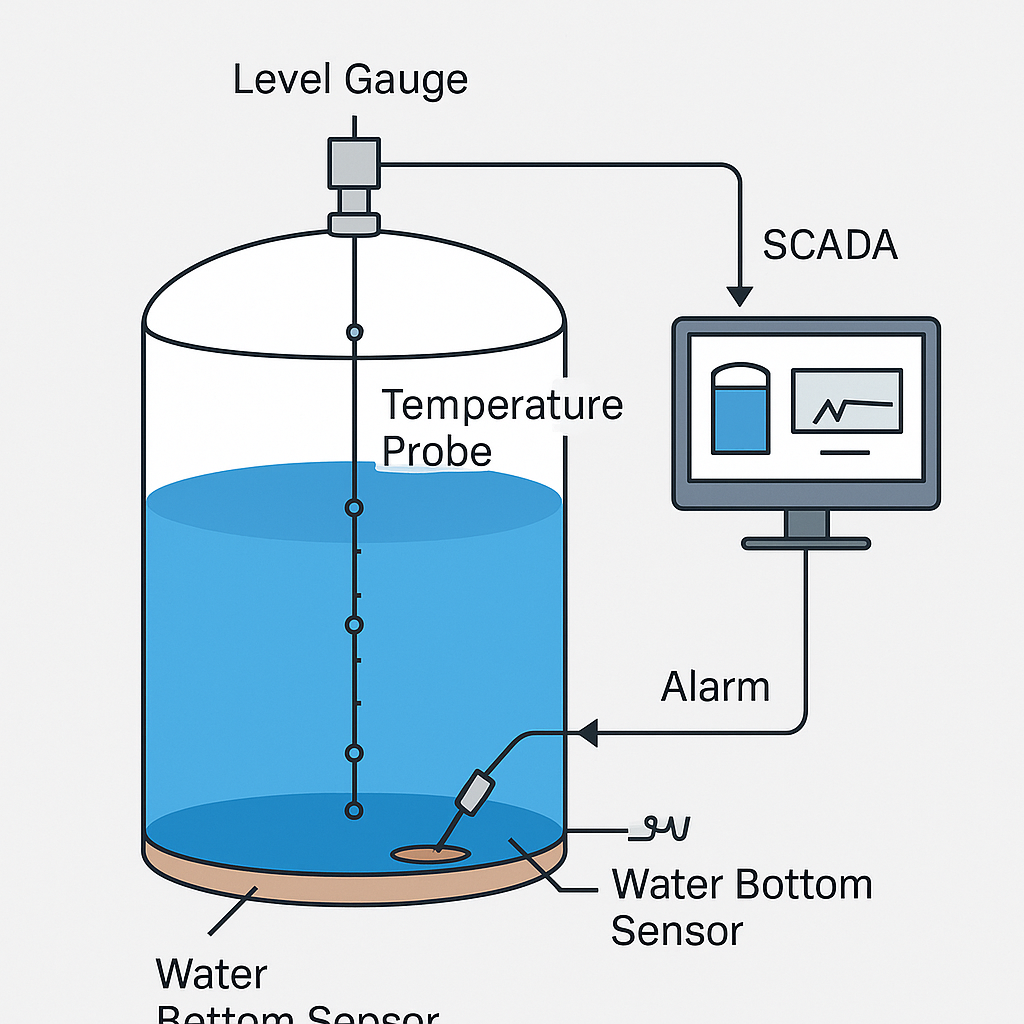

A Tank Gauging System (TGS) is an integrated instrumentation and software solution used to monitor the level, volume, mass, temperature, and pressure of liquids stored in tanks. These systems ensure safe storage, improve inventory accuracy, and support operational efficiency.

A modern TGS typically includes:

Level sensors (e.g., radar, servo, hydrostatic)

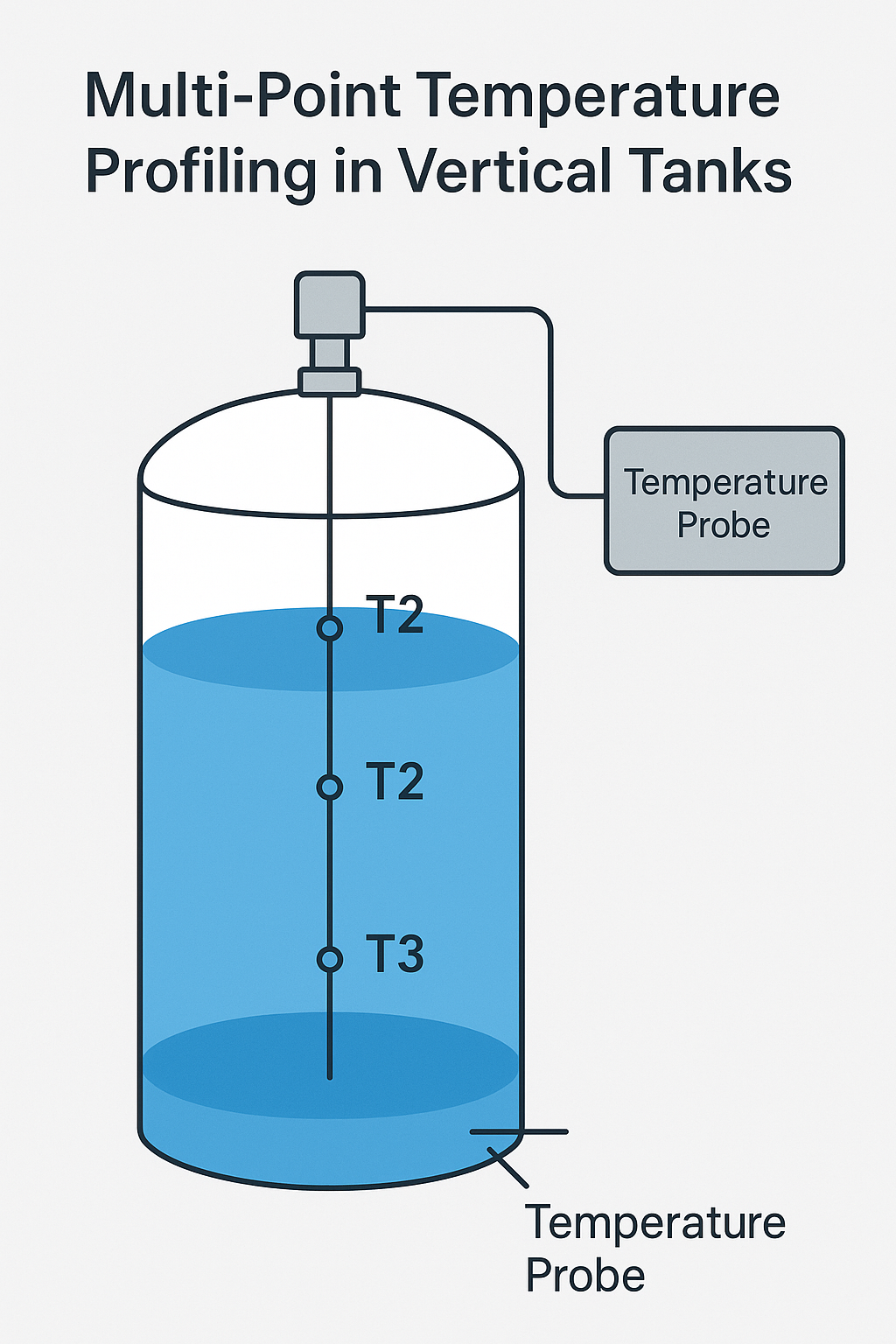

Temperature probes (usually multi-point)

Pressure transmitters

Optional density or water bottom detection

Data acquisition units

Control software or SCADA integration

Key Functions of TGS

| Function | Description |

|---|---|

| Level Measurement | Accurate detection of liquid level using radar, servo, or hydrostatic methods |

| Temperature Sensing | Multi-point temperature profiling for compensation calculations |

| Volume & Mass Calculation | Converts level and temperature data into standard volume or weight |

| Alarm Monitoring | High/low level alarms to prevent overflow or dry run |

| Data Logging | Historical data recording for audit and reporting purposes |

| Communication | Supports protocols like Modbus, HART, Profibus, Foundation Fieldbus |

Why Is It Important?

Inventory Accuracy

Whether you’re managing crude oil, refined fuels, chemicals, or food-grade liquids, precise inventory data is essential for decision-making, trade, and compliance.Operational Safety

A well-configured TGS helps prevent overfilling, product losses, and accidents. With real-time alerts, operators can take corrective actions before issues escalate.Regulatory Compliance

In many regions, legal metrology standards require certified tank gauging systems for custody transfer or bulk transactions.Automation & Integration

TGS can be integrated with ERP or DCS systems to streamline operations and reduce manual errors.

Typical Application Scenarios

| Industry | Use Case Example |

|---|---|

| Oil Terminals | Custody transfer of gasoline or diesel between tanks and trucks |

| Chemical Plants | Monitoring hazardous or volatile chemical tanks |

| LNG/LPG Storage | Cryogenic tank level and pressure monitoring |

| Marine Ports | Real-time tank status for ship loading/unloading |

| Beverage Industry | Raw liquid inventory control in breweries or juice factories |

Choosing the Right TGS

When selecting a TGS, consider the following:

Tank type (vertical, horizontal, floating roof, etc.)

Fluid characteristics (viscosity, volatility, corrosiveness)

Accuracy requirements (e.g., custody transfer vs. process monitoring)

Safety certifications (e.g., ATEX, IECEx, SIL)

Integration needs (SCADA, ERP, PLC systems)

Conclusion

A Tank Gauging System is more than just a collection of sensors—it’s a smart solution that enhances visibility, safety, and profitability in liquid storage operations. With increasing demands for automation and accuracy, TGS has become a cornerstone of modern industrial infrastructure.