Introduction

Chemical production processes often involve hazardous chemicals characterized by flammability, explosiveness, toxicity, high temperature and pressure, and concentration of dangerous sources. Accidents can cause serious damage to human health, the environment, and social stability.

In recent years, digital transformation has begun reshaping the way chemicals are produced and managed. Technologies such as the Industrial Internet, big data, and artificial intelligence are being integrated into safety management, making “Industrial Internet + Safety Production” an inevitable path to improving safety governance. In addition, the national carbon peaking and neutrality goals are accelerating the shift toward new energy sources, such as hydrogen, solar, and wind, which coexist with fossil fuels and introduce new types of safety risks.

To address emerging risks in this new era, chemical safety must rely on technological innovation. This article presents the latest developments in inherently safer technologies (IST) in chemical processes and explores the future trends that support safer and more resilient operations.

1. Understanding Inherent Safety

The concept of inherent safety was first introduced by British safety expert Trevor Kletz in 1976. Unlike traditional approaches that rely on control systems, alarms, or interlocks to mitigate accidents, inherent safety seeks to eliminate or significantly reduce risks at the source.

Absolute safety is rarely achievable in practice, but by applying inherently safer design principles—minimization, substitution, moderation, and simplification—across the entire lifecycle of a chemical process (from R&D, design, construction, and operation to decommissioning), safety risks can be substantially lowered.

These principles form the core protective layer in process safety management and should be implemented before adding active or procedural safety layers such as alarms or operator training.

2. Technical Measures for Inherently Safer Processes

The development of inherently safer process technologies is progressing toward systematization, engineering integration, and intelligent implementation. Key approaches include:

2.1 Process Intensification

Process intensification aims to make chemical processes smaller, cleaner, safer, and more energy-efficient by improving heat/mass transfer and reducing hazardous inventories.

Examples:

Microreactors and membrane reactors: Enhance surface-area-to-volume ratios, improving heat/mass transfer rates by 10–100 times compared to traditional reactors.

Oscillatory baffled reactors, centrifugal distillation, and high-efficiency heat exchangers: Reduce accumulation of energy or hazardous materials.

Green solvents such as ionic liquids: Non-volatile and non-flammable, improve safety and environmental performance.

Advanced technologies like plasma chemistry, ultrasound, and supergravity fields are also being applied to enhance reactivity and reduce hazardous by-products.

2.2 Risk Perception and Early Warning

Abnormal conditions often precede incidents. Real-time monitoring and predictive diagnostics are key to preempting accidents. However, current monitoring systems face challenges:

Lack of predictive modeling for sudden or complex risks.

Limited application of AI, IoT, and big data in dynamic risk monitoring.

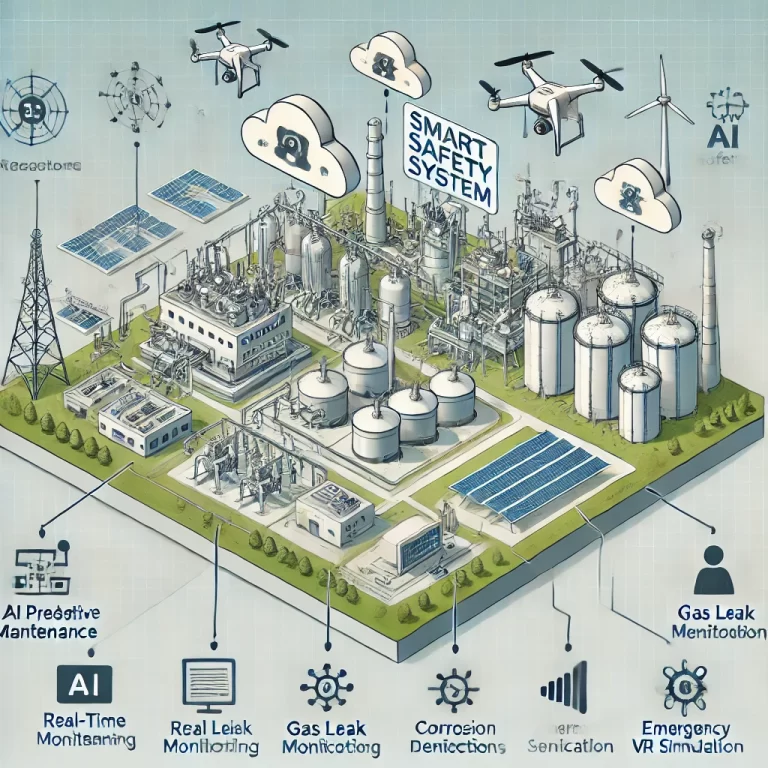

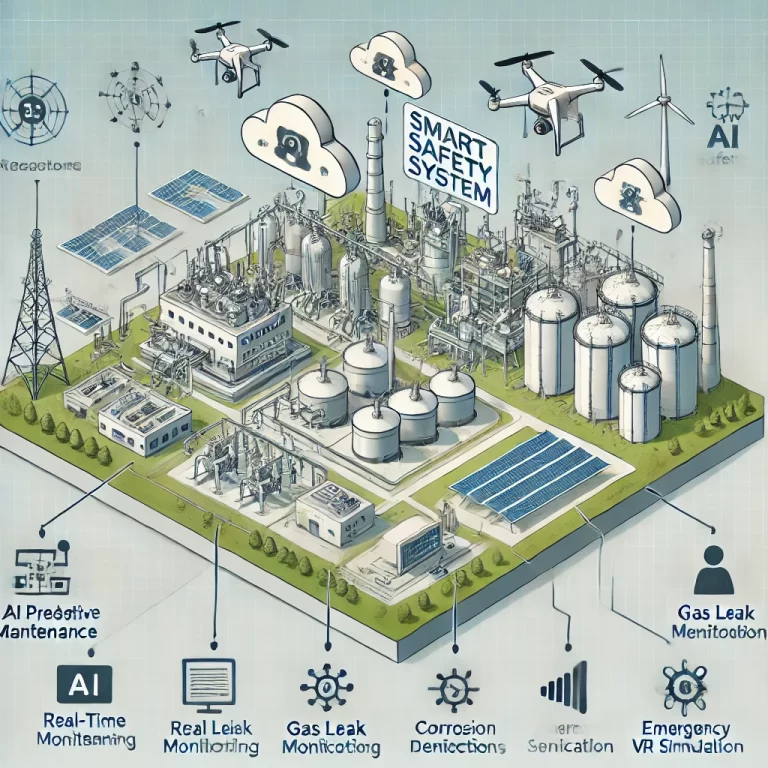

Future developments will focus on building platforms integrating:

Dynamic risk assessment

Equipment health monitoring

Smart gas leak detection

On-line fault diagnosis

Technologies like digital twins, machine learning, and intelligent sensors will be crucial to achieving full lifecycle risk perception and intelligent response.

2.3 Equipment Health and Corrosion Monitoring

Current corrosion inspection relies on techniques like ultrasonic testing, eddy current testing, and phased array imaging. These methods are point-based and lack wide-area coverage.

New trends include:

Non-invasive online monitoring: Using acoustic emission, fiber optics, and guided waves.

Big-data-based corrosion prediction models: Allow remote corrosion risk alerts and lifecycle assessments.

Integration with wearable IoT devices and AI to support preventive maintenance planning.

2.4 Gas Leak Detection and Toxic Monitoring

Most traditional gas sensors are bulky and have low selectivity. With the advancement of nanomaterials, MEMS, and AI, new sensors are emerging:

Micro-nano sensor arrays

Acoustic leak detectors

Non-cooled IR spectral imaging systems

These allow multi-point, multi-gas, and high-speed leak detection. Combining sensor data with coverage algorithms and molecular databases enables early warning and leak source tracing.

3. Risk Control and Emergency Response Technologies

Despite preventive measures, catastrophic risks like explosions or fires still require specialized mitigation strategies.

3.1 Explosion-Resistant Building Retrofit

Many existing chemical plant buildings are fire-rated but not explosion-proof. Retrofit options include:

Reinforced concrete layers on structural walls

High-strength fiber composite reinforcement

Blast-resistant coatings

These methods enhance structural integrity while maintaining constructability and cost efficiency.

3.2 Smart Emergency Response

Accurate situational awareness during an emergency is critical. Technologies being adopted include:

Infrared drones for remote site reconnaissance

Video analytics for real-time hazard visualization

Virtual reality (VR) for immersive training and emergency simulation

These technologies support dynamic risk assessment and rapid response planning through cloud-based platforms, significantly improving accident mitigation capabilities.

Conclusion

Inherently safer design is not a standalone solution but the foundation of a comprehensive risk reduction strategy. By combining inherently safer process technologies with intelligent monitoring, predictive maintenance, and smart emergency systems, the chemical industry can significantly improve its safety level while achieving efficiency and sustainability goals.