Valves are critical components in industrial piping systems, and their performance depends significantly on their manufacturing process. Two primary types of valves based on manufacturing are cast valves and forged valves. Each has distinct characteristics, advantages, and suitable applications. This article explores their differences in terms of production, material properties, appearance, and use cases to help you make an informed selection.

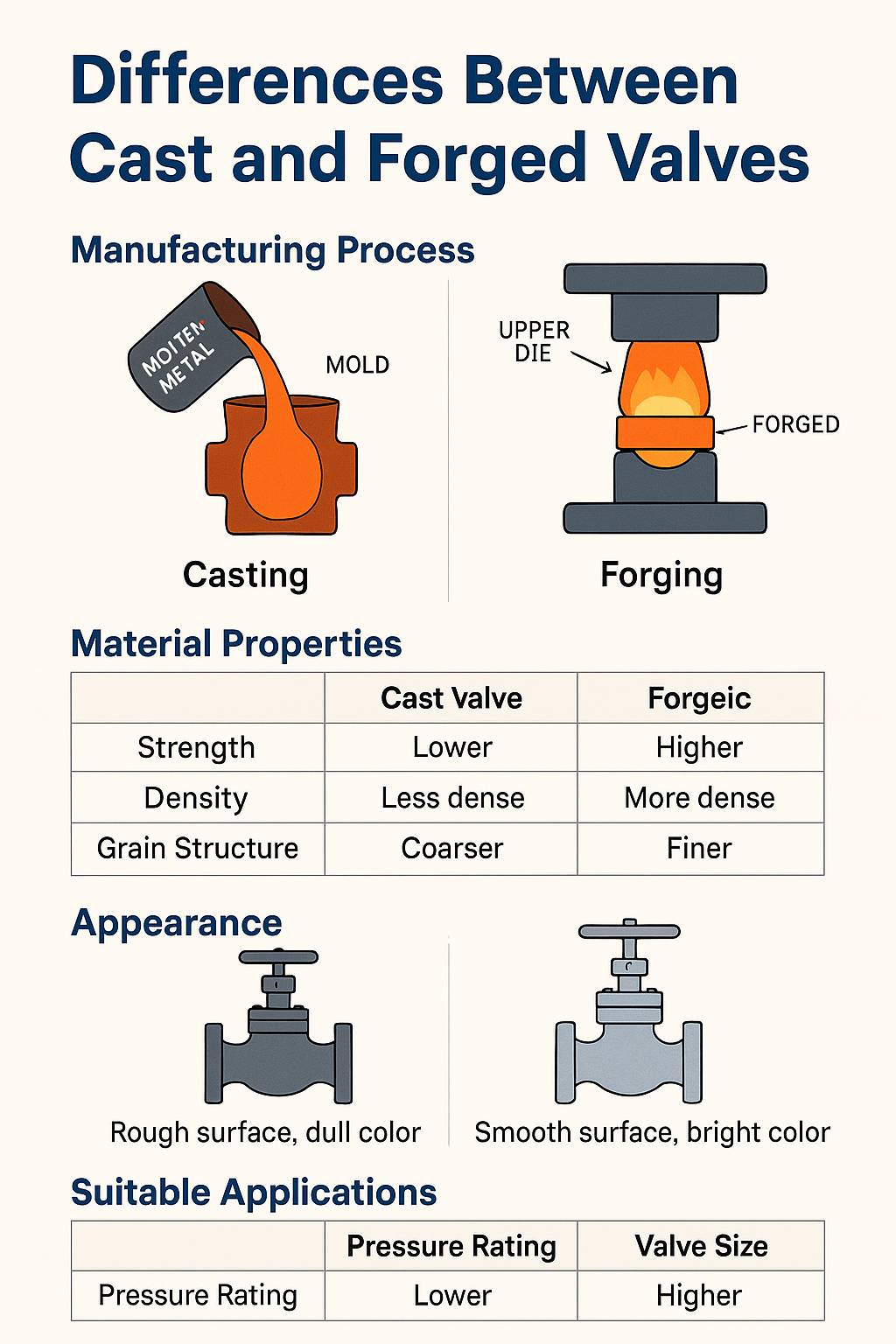

1. Manufacturing Process

Casting (Cast Valves)

Casting involves melting metal into liquid form and pouring it into a mold where it solidifies into the desired shape. This process is ideal for creating complex shapes and internal cavities.

Advantages: Suitable for large sizes and intricate designs.

Common methods: Sand casting, investment casting, and pressure casting.

Limitations: Potential internal defects like porosity or shrinkage.

Forging (Forged Valves)

Forging uses mechanical force to shape heated metal into the desired form through plastic deformation.

Advantages: Produces high-strength, dense, and durable parts.

Types: Open-die forging, closed-die forging.

Limitations: Higher production cost; less suitable for complex shapes.

2. Material Properties

| Feature | Cast Valves | Forged Valves |

|---|---|---|

| Strength | Moderate; more prone to defects | High; superior mechanical integrity |

| Density | Lower; potential for voids | Higher; excellent compactness |

| Impact Resistance | Lower | Excellent |

| Consistency | Less uniform grain structure | Fine-grained, uniform structure |

3. Visual and Physical Characteristics

Cast Valves

Surface: Rougher finish, dull color.

Sound: Dull thud when tapped.

Typical Issues: May have sand holes, blowholes.

Forged Valves

Surface: Smooth, bright finish.

Sound: Clear, ringing tone when tapped.

Typical Issues: Grain flow misalignment (rare with modern processes).

4. Applications

| Application Type | Recommended Valve Type |

| Low-pressure, large diameter | Cast Valve |

| High-pressure, high-temperature | Forged Valve |

| Cost-sensitive projects | Cast Valve |

| Critical operations (oil, gas) | Forged Valve |

5. Standards & Testing

Cast Valves: ASTM A216 (carbon steel), ASTM A351 (stainless steel).

Forged Valves: ASTM A105 (carbon steel), ASTM A182 (stainless steel).

Testing Methods:

Castings: X-ray inspection, magnetic particle testing (due to possible porosity).

Forgings: Ultrasonic testing for internal consistency.

✅ Key Takeaways

Choose cast valves for low-pressure, large-diameter applications where cost is a concern.

Opt for forged valves for high-pressure, high-temperature, or critical services requiring superior mechanical strength.

Selecting the right valve type ensures system safety, longevity, and performance.