1. Importance of Temperature Measurement in Reactors

Temperature control is critical in chemical reactors to ensure reaction efficiency, product quality, and operational safety. However, the agitator and complex flow patterns inside reactors impose significant challenges on the design and installation of temperature sensors, especially their thermowells.

2. Heat Distribution in Reactors

The temperature distribution, or thermal field, inside a reactor is influenced by multiple factors:

Heating/Cooling Methods:

Jacket Heating/Cooling: Heat transfers from the reactor wall to the interior, often causing high wall temperatures and cooler core zones, particularly for viscous fluids.

Internal Coils or Immersion Heaters: Provide more uniform heating but may cause localized hotspots if improperly arranged.

Electrical Heaters: Create concentrated heat zones, requiring vigorous agitation for uniformity.

Agitation Characteristics:

Impeller Type: Anchor or ribbon impellers suit high-viscosity materials, minimizing wall-to-core temperature gradients. Turbine or propeller impellers promote strong mixing in low-viscosity systems.

Speed and Position: Insufficient speed may result in stratification and temperature dead zones.

Material Properties:

Thermal Conductivity: Low conductivity materials are prone to large temperature gradients.

Viscosity: High-viscosity fluids reduce convective heat transfer, compromising thermal uniformity.

Reactor Geometry and Environment:

High aspect ratios can lead to vertical temperature gradients. Baffles are often used to disrupt vortex formation and improve mixing.

CFD Simulation is increasingly applied to predict 3D thermal fields and identify hotspots or cold zones, guiding optimal sensor placement.

3. Temperature Sensor Selection and Installation

Two main temperature measurement approaches are adopted:

3.1 Non-Contact Measurement

Infrared (IR) sensors measure surface temperatures based on blackbody radiation laws.

Application Example: In sulfur melting reactors, where high-viscosity materials and steam interference cause damage to traditional sensors, IR sensors provide reliable surface temperature readings for process control.

3.2 Contact Measurement

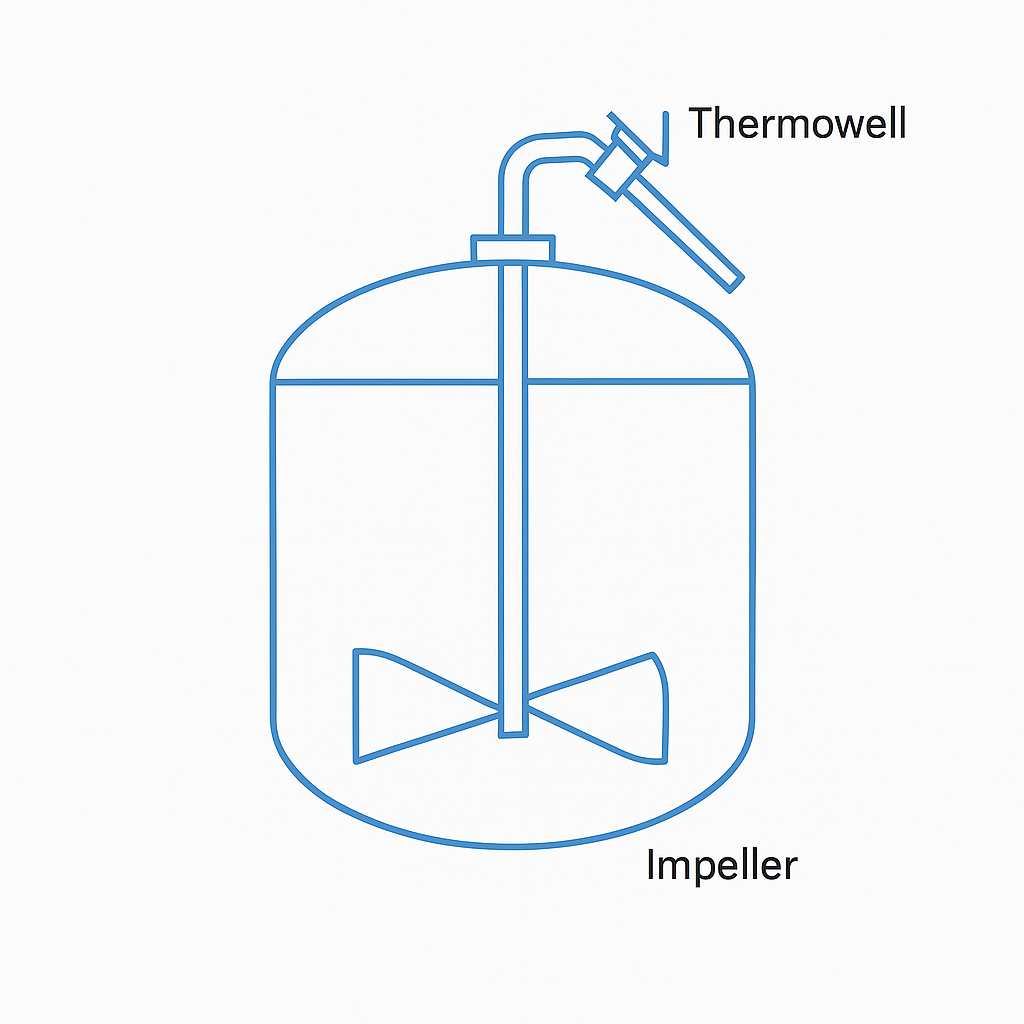

Resistance temperature detectors (RTDs) or thermocouples installed inside thermowells are widely used. However, the thermowell design and placement are critical in the agitated environment.

4. Challenges of Thermowell Installation in Reactors

4.1 Mechanical Damage Risks

Impeller Blade Collision: High-speed rotation and viscosity changes can cause impeller blades to hit thermowells, leading to bending or fracture.

Fluid Dynamic Forces: Von Kármán vortex shedding around cylindrical thermowells can induce high-frequency vibrations (>100Hz), accelerating fatigue failure.

Abrasive Wear and Corrosion: Suspended particles in the reactant medium can erode the thermowell surface, while corrosive environments exacerbate metal degradation.

5. Best Practices for Thermowell Design

✅ Design Optimization

Follow ASME PTC 19.3 TW-2016 guidelines for thermowell strength and vibration analysis.

Use tapered thermowells to minimize vortex-induced vibrations.

✅ Safety Clearance

Maintain a minimum clearance of 3× impeller blade width between thermowell and blades (e.g., 100mm blade requires 300mm clearance).

Install at a radial offset angle ≥15° to avoid alignment with impeller plane.

✅ Periodic Inspection

Perform eddy current testing (ECT) every 6 months to detect surface cracks.

Use ultrasonic thickness measurements to monitor wear on the leading surface, ensuring minimum wall thickness remains above 70% of design value.

✅ Emergency Handling

Establish protocols for thermowell failure detection and replacement to avoid unplanned downtime.

6. Conclusion

Effective temperature sensor design and installation in reactors require a balance between precise thermal monitoring and mechanical durability. By combining CFD simulations, robust thermowell designs, and regular inspections, plants can achieve reliable temperature control even in demanding agitated systems.