In process industries such as petrochemicals, oil & gas, and power plants, shut-off valves (SDVs) are critical components of safety and process control systems. They are often controlled by Distributed Control Systems (DCS) or, in safety-critical applications, by Safety Instrumented Systems (SIS).

A common question during system design or plant operation is:

“Can shut-off valves in a DCS system be equipped with bypass lines?”

Let’s explore this topic from safety, operational, and engineering perspectives.

🔒 Why Shut-Off Valves Exist: Safety First

Shut-off valves are designed to isolate a process section during emergencies, maintenance, or abnormal conditions. When a shutdown signal is issued by the DCS or SIS, these valves must fully block the flow to:

Protect downstream equipment.

Prevent hazardous material release.

Ensure personnel safety.

If a bypass line is installed, it provides an alternative flow path around the shut-off valve. While this can improve process continuity during maintenance, it can also compromise the integrity of the isolation.

🚨 Bypass Lines: Advantages and Risks

✅ Advantages of a Bypass Line

Enables online maintenance of the shut-off valve without stopping the process.

Reduces production downtime for systems where flow interruption is highly undesirable (e.g., inert gas systems or utilities).

Facilitates pressure equalization across the valve during startup.

❌ Risks of a Bypass Line

Loss of isolation: If the bypass valve is left open or leaks, the shut-off function is defeated.

Potential for human error during maintenance.

Adds complexity to operational and safety procedures.

🌐 International Standards and Best Practices

IEC 61511 / API 553 Guidance:

For Safety Instrumented Functions (SIF) with SIL 2 or higher, bypass lines are generally prohibited unless justified by a risk assessment.

If a bypass is essential, it should be:

Equipped with double block and bleed (DBB) valves.

Locked in the closed position under permit-to-work (PTW) or lockout-tagout (LOTO) procedures.

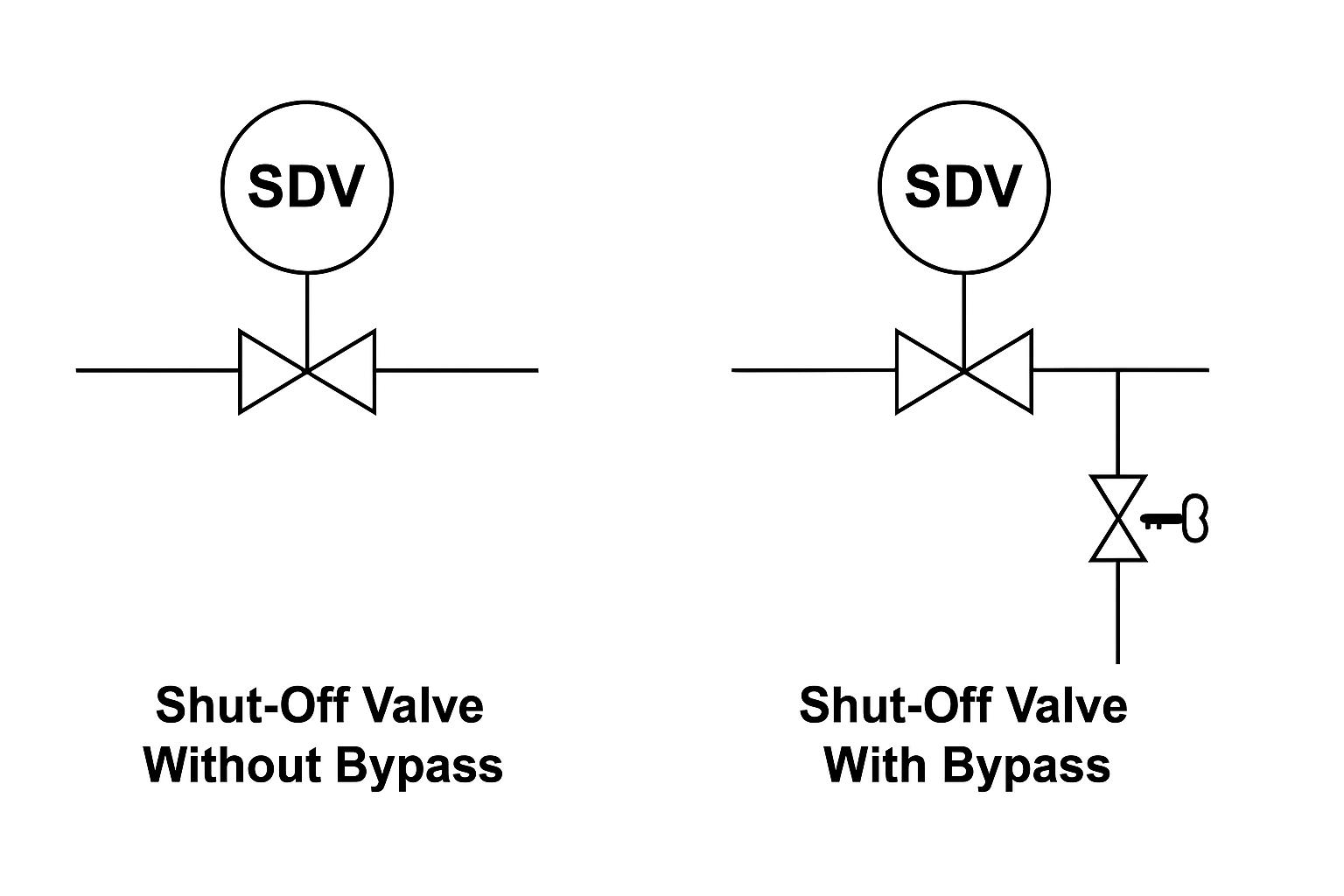

Clearly shown on P&ID diagrams with proper operational notes.

Industry Practice:

Many companies only allow bypasses on non-critical shut-off valves, such as those in utility or auxiliary systems. In high-risk process areas, bypasses are often avoided altogether.

🛠️ When Is a Bypass Acceptable?

Bypass lines may be justified in:

Utility lines (e.g., nitrogen, cooling water) where safety risks are minimal.

Process streams requiring continuous flow for technical reasons.

Systems where isolation is achieved by multiple independent barriers.

However, in all cases, strict operational controls must be implemented to prevent accidental bypassing of the shut-off function.

📝 Key Design Recommendations

Avoid bypass lines for ESDVs (Emergency Shut-Down Valves) controlled by SIS.

For DCS-controlled process isolation valves, perform a Hazard and Operability (HAZOP) study before deciding on bypasses.

If a bypass is installed, include:

Manual valves with locks.

Clear labeling and P&ID indications.

Operational procedures for controlled use.

📊 Conclusion

While bypass lines on DCS system shut-off valves may improve process flexibility, they introduce potential risks that must be carefully assessed. In safety-critical applications, it is often best practice not to include bypasses unless a detailed risk analysis demonstrates it is both safe and necessary.

A simple rule of thumb:

“If the shut-off valve protects life or the environment, avoid bypassing it.”