1. Introduction: Why Drum Level Matters

In power plants, cogeneration systems, and any facility involving boilers, the term “drum level” is critical. While it may seem like a basic parameter, drum level is actually a complex topic encompassing measurement principles, control strategies, and failure management. Improper drum level control can lead to reduced boiler efficiency at best—and catastrophic accidents at worst.

2. The Drum Level Is the “Lifeline” of the Boiler

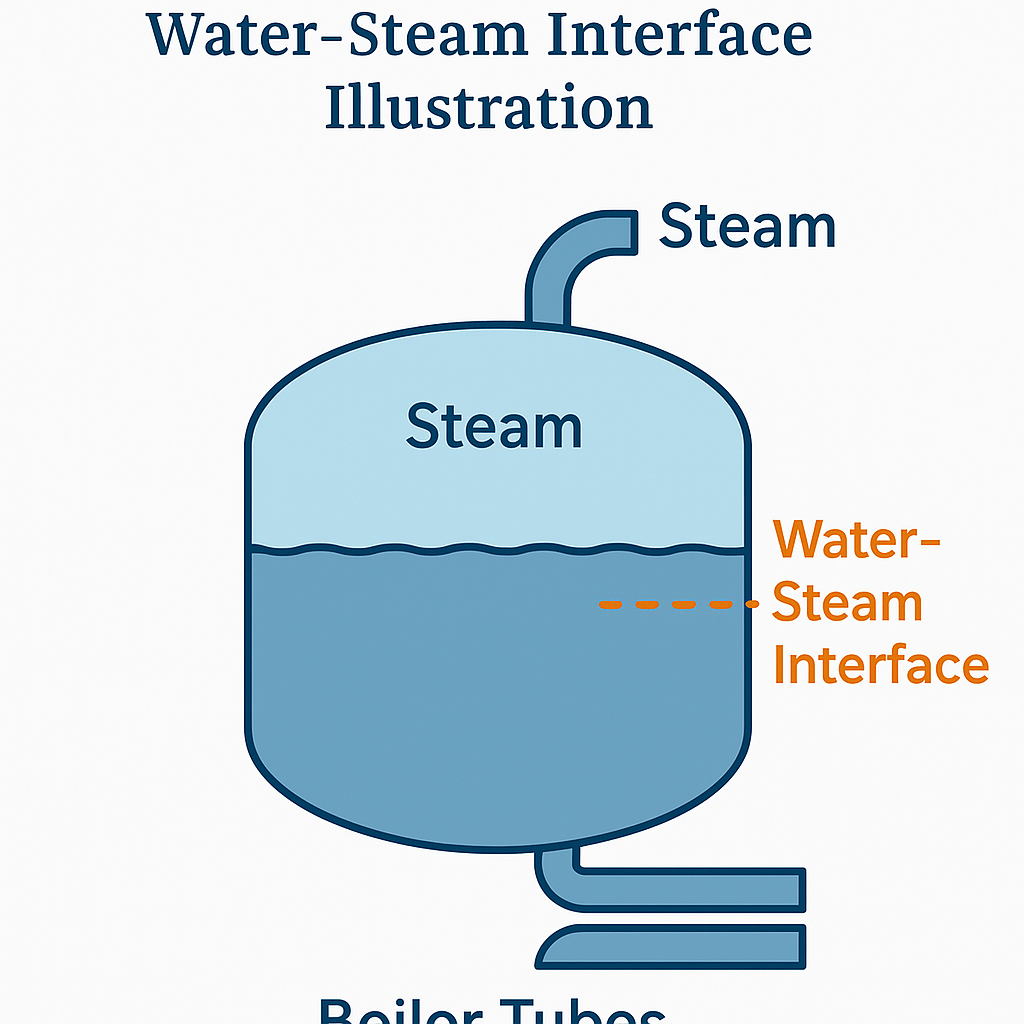

The boiler drum (a cylindrical vessel at the top of the boiler) contains a dynamic mixture of steam and water. Its sole function is phase separation—steam rises to the top while water settles at the bottom. The interface between the two is the “drum level.”

If the level is too low, boiler tubes risk overheating and rupture. If too high, water may carry over into the steam turbine, causing water hammer and equipment damage. Unstable or inaccurate level measurement can also result in boiler trips or system pressure shocks.

3. The Drum Level Is Not a Static Parameter

Drum level is inherently unstable. During load increases, the evaporation rate surges, generating bubbles in the water. This can cause a false drop in the level followed by a rapid “surge” as bubbles expand, creating a misleading signal. This phenomenon is known as foaming-induced false level.

Operators and instruments often struggle to distinguish between real level changes and those caused by foaming, leading to misjudgments.

4. Common Drum Level Measurement Methods

| Method | Advantages | Disadvantages | Suitability |

|---|---|---|---|

| Differential Pressure (DP) Transmitter | Mature, fast response, easy DCS integration | Affected by steam line blockage, condensate stability, and density changes | Most common, but maintenance-intensive |

| Electrode Level Sensor | Low cost, simple | Only provides point-level (high/low) alarms, not continuous | Suitable for limit alarms |

| Radar/Ultrasonic Level Transmitters | No contact, advanced algorithms | Affected by steam, bubbles, high-temp limits | Radar (specialized) usable in high-temp drums; ultrasonic not recommended |

| Magnetic Level Indicator (MLI) | Visual, robust, no power required | No remote signal, prone to float sticking | Best for local observation |

| High-Temp Tuning Fork Switch | Extreme temp/pressure tolerance | Point detection only | Ideal for interlocks & extreme condition alarms |

5. Drum Level Control Strategies

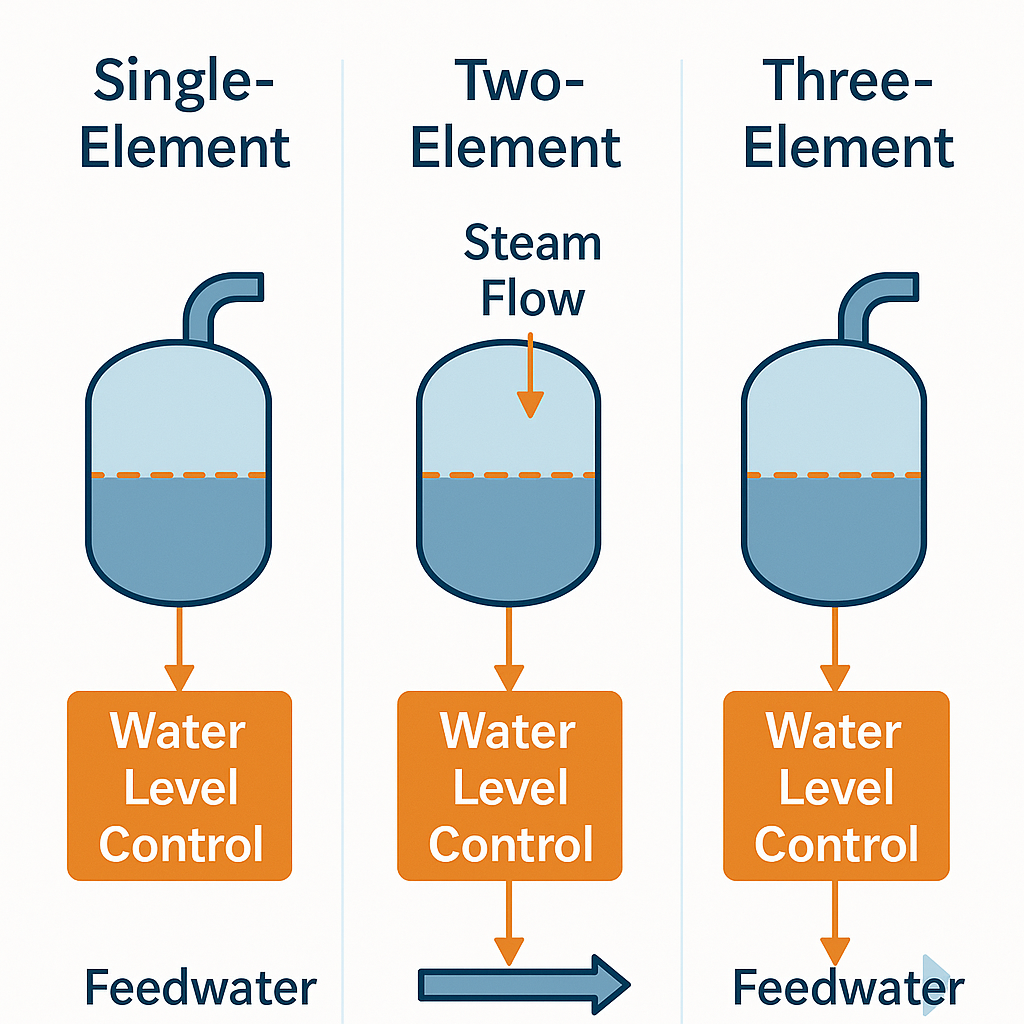

5.1 Single-Element Control

Uses only the drum level signal to control feedwater. This method is simple but inadequate for fast-changing loads, leading to delayed response and instability.

5.2 Two-Element Control

Adds steam flow signal. As steam demand increases, feedwater is preemptively added to prevent a drop in level. Suitable for medium-sized boilers.

5.3 Three-Element Control

Incorporates drum level, steam flow, and feedwater flow. This enables dynamic compensation and predictive control. Considered the industry standard for large boilers.

6. Hidden Pitfalls in Drum Level Control

The biggest challenge in drum level control is not insufficient technology, but the misleading nature of the signal:

It reacts too strongly (overshooting due to foaming)

It has feedback delay (instrument lag)

It often appears correct while being fundamentally inaccurate

Poor understanding of these dynamics often causes operators to over-correct, making things worse.

Modern solutions include:

Model Predictive Control (MPC)

Adaptive PID algorithms

AI-based diagnostics

Digital twins for system behavior simulation

7. Conclusion: Drum Level as the “Boiler’s Personality”

Controlling drum level is not just a technical skill—it’s an art. It reflects the combined effect of evaporation rate, feedwater supply, combustion dynamics, and operator behavior. A stable drum level is a reliable indicator of boiler health.

Engineers who understand the “personality” of drum level fluctuations become the cornerstone of boiler operation teams.