1. Introduction

The review of instrumentation construction drawings is a critical step to ensure project safety, efficiency, and cost-effectiveness. A thorough and systematic review helps identify potential issues in advance, avoiding errors and rework during construction. This document outlines the key aspects and best practices for reviewing instrumentation drawings.

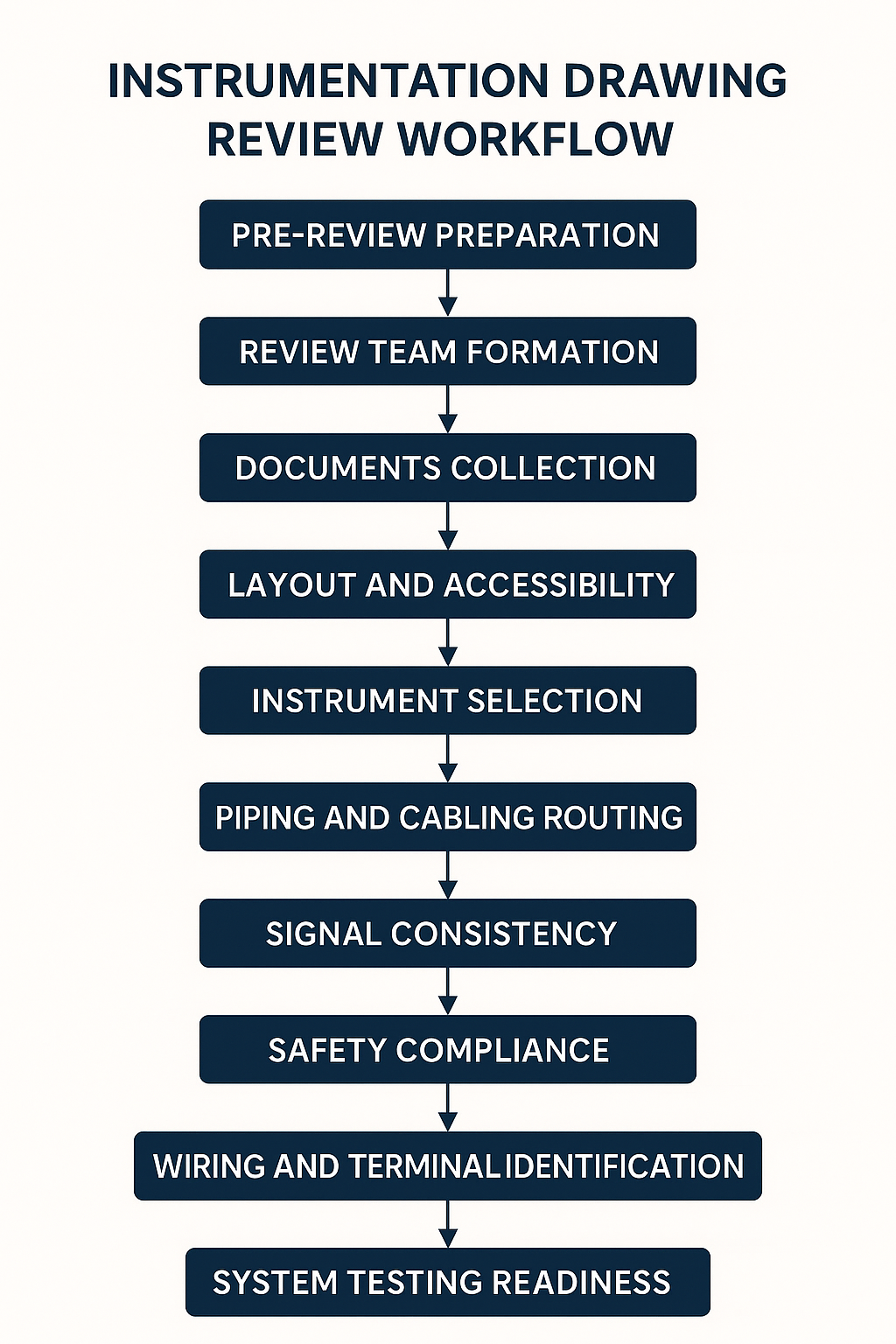

2. Pre-Review Preparation

As the saying goes, “sharpening the axe will not delay the job of cutting wood.” Proper preparation lays a solid foundation for a successful review process.

2.1 Collect All Relevant Documentation

Ensure all necessary documents (P&IDs, specifications, loop diagrams, equipment data sheets, layout drawings, etc.) are complete and accurate.

Include project standards, client-specific requirements, and applicable codes and regulations.

2.2 Form a Qualified Review Team

Select team members based on their professional background, experience, and communication ability.

Include personnel from instrumentation, process, electrical, and construction disciplines as needed.

2.3 Establish a Review Plan

Define scope, timeline, responsibilities, and review procedures in advance.

Prioritize high-risk areas or critical systems for deeper scrutiny.

3. Seven Key Aspects of Drawing Review

3.1 Instrument Selection

Verify that instrument type, model, specification, and performance align with design intent and process requirements.

Example: Use RTDs or thermocouples for high-temperature measurements; use high-precision pressure transmitters for low-pressure differentials.

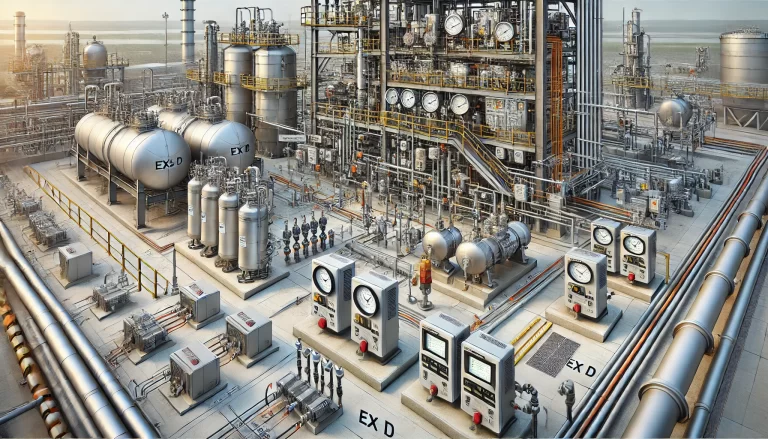

3.2 Layout and Accessibility

Check if instruments are positioned for easy access, visibility, and safe maintenance.

Ensure that layouts align with process flow and minimize interference with other systems.

3.3 Piping and Cabling Routing

Review line routing to ensure it avoids unnecessary bends or crossings.

Confirm mounting methods, supports, and protection measures meet mechanical and safety standards.

Prevent pipe and cable interference to reduce mechanical wear or signal disturbance.

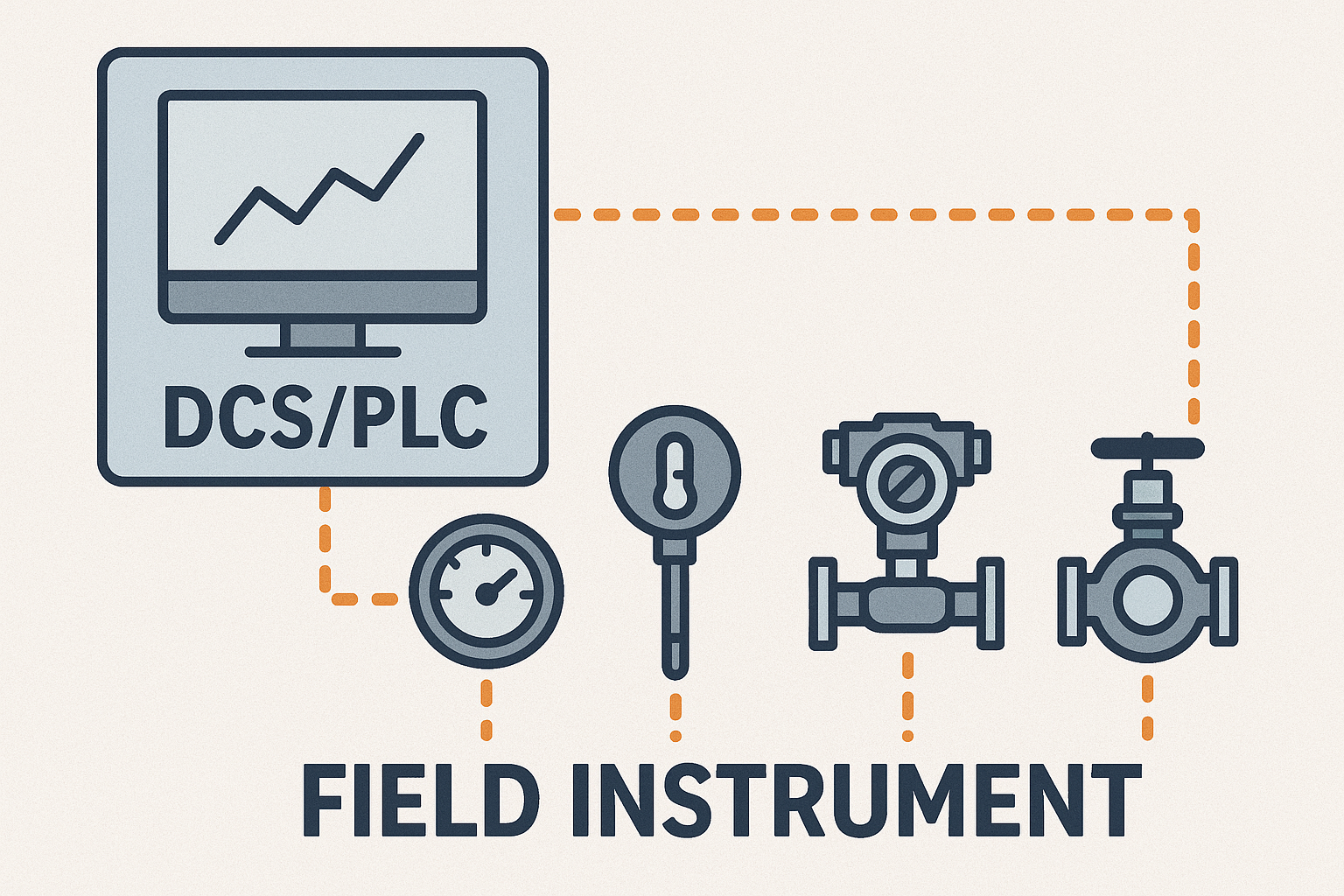

3.4 Signal Consistency

Confirm signal types (analog, digital, pulse), ranges, and wiring are consistent across systems.

Validate conversion accuracy and clarity of signal display for operator readability.

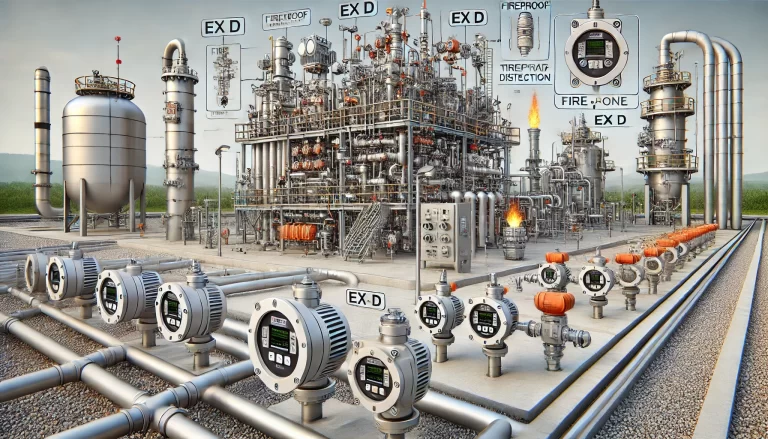

3.5 Safety Compliance

Ensure designs include proper protection against explosion, fire, moisture, and environmental hazards.

Confirm safety zones and classification areas are respected in equipment placement.

3.6 Wiring and Terminal Identification

Cross-check wiring diagrams for correctness, including wire gauge, terminal IDs, and cable labeling.

Follow national or project-specific wiring codes to prevent open circuits, shorts, or miswiring.

3.7 System Testing Readiness

Verify that test and commissioning procedures are documented.

Confirm provisions for functional tests, performance validation, and long-term stability checks.

4. Review Notes and Best Practices

4.1 Maintain Precision and Discipline

Every review should be carried out with a meticulous, detail-oriented mindset.

4.2 Document Findings and Recommendations

Keep a record of all comments, corrections, and suggestions made during the review.

4.3 Facilitate Cross-Team Communication

Coordinate closely with design, process, and construction teams to clarify intent and resolve conflicts.

4.4 Use Review Tools and Technology

Leverage digital review platforms, 3D models, and checklists to enhance efficiency and accuracy.

5. Conclusion

Instrumentation drawing review is a key quality control step that safeguards safety, reliability, and project success. A structured and thorough review process ensures that instrumentation systems meet both functional and operational expectations—paving the way for smooth construction and long-term performance.