Introduction

Temperature is one of the most significant environmental factors that affect the accuracy and longevity of load cells. Whether you’re measuring forces in an outdoor setting or in a climate-controlled facility, temperature fluctuations can lead to errors in readings.

This article explains how temperature affects load cell performance, why it matters, and how to mitigate temperature-related errors for consistent measurements.

1. How Temperature Affects Load Cells

Load cells rely on strain gauges to measure mechanical force. These gauges are made of metal foil or wires, which change their resistance when stretched or compressed. However, temperature changes also affect the resistance of the strain gauge material, leading to:

Signal drift (increased or decreased output)

Non-linearity (output is no longer proportional to the applied load)

Zero shift (the sensor’s baseline reading changes without any load applied)

2. Temperature Coefficient of Sensitivity (TCS)

The temperature coefficient of sensitivity (TCS) describes how much the output of the load cell changes with temperature. This is typically expressed as:

TCS = ±0.02% F.S./°C

Where:

F.S. stands for Full Scale, the maximum rated output of the load cell

A TCS of ±0.02% F.S./°C means the output may change by ±0.02% for every degree Celsius the temperature changes.

For example, if a load cell is rated at 1000 N and has a TCS of ±0.02% F.S./°C, a 1°C change in temperature could cause the reading to shift by ±0.2 N.

3. Effects on Accuracy and Stability

| Temperature Effect | Impact on Load Cell Performance | Consequence |

|---|---|---|

| Zero drift | Output shift without load | Inaccurate baseline reading |

| Sensitivity shift | Load cell output changes with temperature variation | Reduced measurement accuracy |

| Non-linearity | Output curve deviates from linearity | Loss of proportionality (error in load calculation) |

4. Environmental Temperature Challenges

Extreme Outdoor Conditions: In outdoor applications, load cells are often exposed to varying temperatures due to weather or seasonal changes.

Hot Work Environments: Manufacturing processes such as metal forging, or high-temperature furnaces can drastically impact sensor performance.

Cold Storage or Freezer Units: Some load cells may experience sluggish response or frozen signals when exposed to freezing conditions.

5. How to Mitigate Temperature Effects

✅ Use Temperature-Compensated Load Cells

Modern load cells come with built-in temperature compensation—ensuring that the output remains stable across a wide temperature range.

✅ Choose Load Cells with Low TCS

For high-precision applications, select load cells with a low temperature coefficient of sensitivity (≤ ±0.01% F.S./°C).

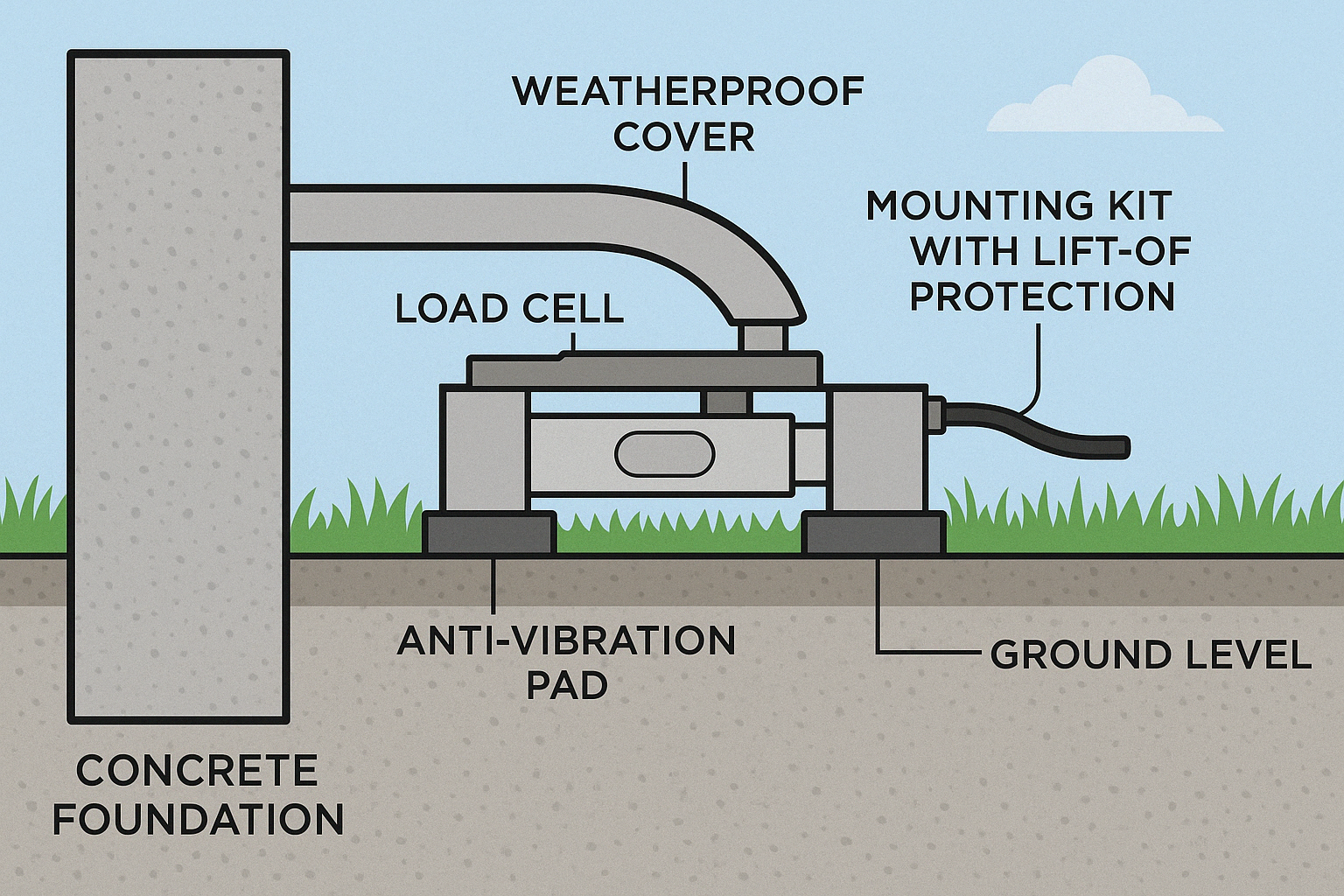

✅ Install Sensors in a Controlled Environment

Where possible, ensure that load cells are installed in temperature-controlled enclosures or environmentally shielded areas to minimize temperature fluctuations.

✅ Allow Warm-up Time

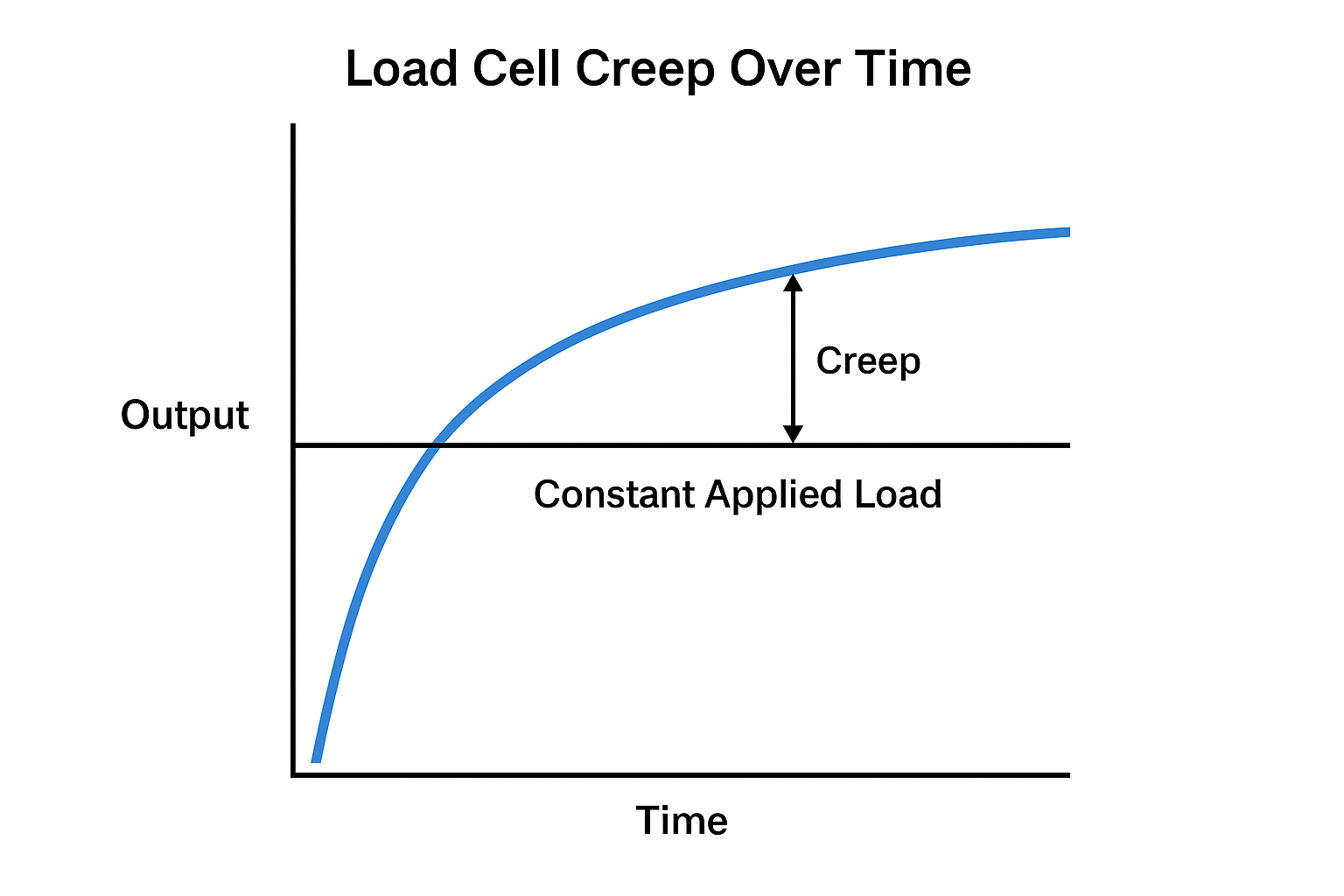

Allow your load cell to stabilize before taking measurements, especially if the temperature has changed rapidly (such as moving from one environment to another).

✅ Regular Calibration

Because temperature can cause gradual shifts over time, recalibrate your load cell annually or after significant temperature changes to maintain accuracy.

✅ Use External Temperature Compensation

In high-temperature environments, install external temperature sensors near the load cell to monitor and adjust readings based on real-time temperature data.

6. Real-World Example: Weighing Systems in Food Manufacturing

In food manufacturing, where product weight accuracy is critical, temperature fluctuations (e.g., from ovens or refrigerators) can cause load cells to experience non-linearity or zero drift. Temperature-compensated load cells ensure stable readings even when environmental temperature changes.

7. Conclusion

Temperature has a significant impact on load cell performance, especially in environments with frequent or extreme temperature changes. Understanding these effects and taking proper precautions—such as using temperature-compensated sensors or installing in temperature-controlled environments—will help maintain measurement accuracy and system reliability over time.

Accurate readings require more than just good sensors—they require the right environmental conditions.