In industrial automation systems, “level” may seem like a basic variable. But anyone with on-site experience knows: level measurement is an underrated technical challenge.

You’re not dealing with laboratory-grade pure water, but with aggressive, sticky, volatile, or high-temperature liquids—each with its own “personality.” The wrong level device selection can lead to instrument failure, production stoppages, or even serious accidents.

Worse yet, misuse of level transmitters and level switches is common. Some users apply a transmitter for switch-level control, while others install devices without understanding the selection criteria—resulting in frequent alarms, control failures, and unwanted shutoffs.

This article explains two key points:

Why different types of liquids require different level measurement strategies.

The functional difference between level transmitters and level switches—and how they should work together.

1. Level Transmitter ≠ Level Switch

Let’s clarify a common misconception: Level transmitters and level switches are two fundamentally different devices, with distinct purposes and operating principles.

In simple terms:

A level transmitter tells you: “The liquid level is currently 1.46 meters”—ideal for continuous monitoring and PID control.

A level switch tells you: “Has the liquid reached 1.5 meters? If yes, stop the pump.”

In safety-critical environments, both are often used together: one for real-time measurement, the other for redundant protection.

2. Different Liquids Require Different Solutions

A liquid’s behavior and physical properties determine your measurement strategy. Below are six common challenging scenarios, often responsible for failed level applications.

① Corrosive Liquids

Examples: Sulfuric acid, hydrochloric acid, caustic soda, ammonia.

Challenges: Metal parts rapidly corrode, causing sensor failure or leakage.

Recommendations:

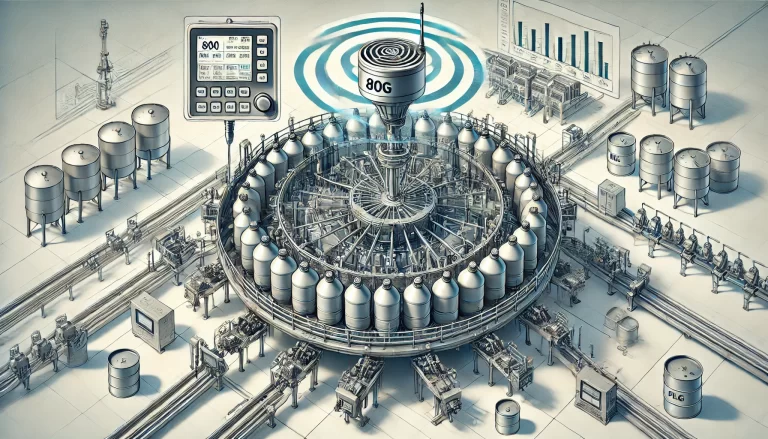

Transmitter: Use non-contact radar (e.g., 80 GHz) or PTFE-lined magnetic level gauges.

Switch: Use anti-corrosion float switches, tuning forks, or coated conductive probes.

Best combo: Radar for continuous level, switch for high-level overflow protection.

② High-Viscosity Liquids

Examples: Resin, bitumen, syrup, grease.

Challenges: Severe buildup on sensors, affecting accuracy; float types fail.

Recommendations:

Transmitter: 80 GHz radar or weighing-type level systems.

Switch: Avoid floats or forks; use anti-stick capacitive probes.

Best combo: Radar + weighing system for redundancy and long-term reliability.

③ Flammable or Explosive Liquids

Examples: Gasoline, ethanol, solvent oils, formaldehyde.

Challenges: Vapor ignition risk; sensors must be explosion-proof and anti-static.

Recommendations:

Transmitter: Intrinsically safe radar or hydrostatic pressure sensor.

Switch: Certified Ex ia/Ex d float or tuning fork switch.

Important: Compliance with explosion-proof certificates and use of intrinsic safety barriers is mandatory.

④ Liquids with Foam or Suspended Solids

Examples: Wastewater, foaming agents, pulp slurry, emulsions.

Challenges: Foam distorts or absorbs radar/ultrasonic signals; poor accuracy.

Recommendations:

Transmitter: 80 GHz radar, guided wave radar, or weighing systems.

Switch: Avoid conductive probes; use heavy-duty floats or anti-foam intelligent probes.

Suggested setup: Radar + differential pressure + limit switch (triple protection).

⑤ High-Temperature / High-Pressure Liquids

Examples: Thermal oil, boiler water, reactor fluids.

Challenges: Extreme heat and pressure can damage sensors or cause leakage.

Recommendations:

Transmitter: High-temp radar with ceramic seal or DP transmitters with cooling extensions.

Switch: Heat-resistant tuning forks or magnetic float types with insulation.

Note: Fork switches rated up to 400°C are reliable in thermal applications.

⑥ Hygienic Liquids (Food/Pharma Grade)

Examples: Purified water, dairy, medical fluids, injectable solutions.

Challenges: Cleanliness is top priority; all sensors must allow CIP/SIP.

Recommendations:

Transmitter: Hygienic-grade capacitive or guided radar, 316L polished body.

Switch: Hygienic tuning fork or conductivity switch (FDA-compliant).

Tip: Use tri-clamp sanitary connections, not threaded types.

3. Optimal Configuration: Transmitter + Switch

A robust level monitoring system uses a dual-device approach:

Level transmitter provides real-time data to PLC/DCS for continuous control.

Level switch serves as a safety interlock for high/low level alarms and pump protection.

This dual strategy ensures both operational efficiency and safety.

4. Common Selection Errors Can Be Costly

Using conductive probes in corrosive liquids → casing erosion → fluid leakage

Using float switches in sticky fluids → float jams → no alarm/action

No redundant limit switch → radar signal drifts → tank overflow

Ignoring explosion-proofing → vapor ignition → safety incidents

You may save a few hundred dollars on instrumentation—but at the risk of tens of thousands in downtime, damage, or injury.

5. Final Thoughts

A truly reliable level measurement system is not built on the most expensive device—but on a well-thought-out combination of:

Understanding the process conditions

Matching instruments to liquid characteristics

Designing a measurement + alarm + control strategy

In this system:

The transmitter senses what’s happening.

The switch decides whether to act.

They’re complementary tools, not interchangeable ones.