Chemical instrumentation plays a vital role in ensuring the safe and stable operation of chemical production processes. Proper selection must comprehensively consider process conditions, media characteristics, environmental requirements, measurement accuracy, and more. This guide presents the core logic and key steps for instrument selection in chemical industries.

1. Define Process Requirements: Start with the Measurement Objective

1.1 Measurement Parameters and Ranges

Identify the type of parameters to be measured: flow, pressure, temperature, level, composition, etc.

Define their respective ranges, e.g., pressure: 0–10 MPa, temperature: –20 to 200°C.

Assess fluctuation behavior:

High-frequency pulsation (e.g., pump outlet pressure)

Slow variation (e.g., storage tank level)

Transient peaks (e.g., surge pressure in pipelines)

These influence the required response speed and pressure resistance.

1.2 Medium Characteristics

Physical state: gas, liquid, steam, or slurry?

Assess whether the medium has high viscosity, corrosiveness, flammability, toxicity, or tendencies to crystallize or vaporize.

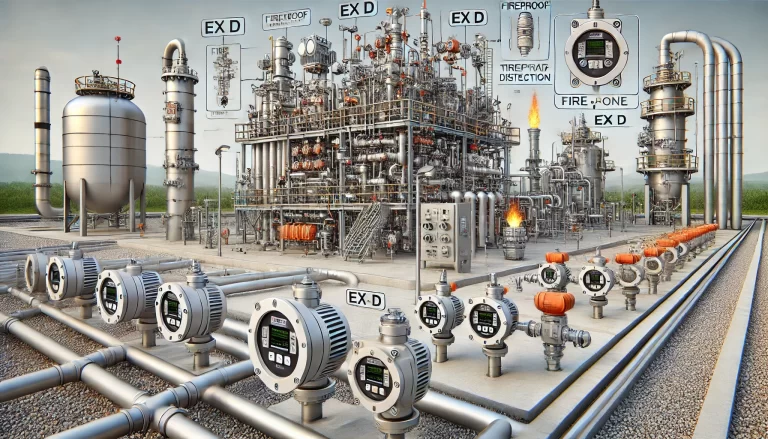

Example: Hydrochloric acid requires corrosion-resistant materials; LPG demands explosion-proof design.

Chemical compatibility: Ensure wetted parts (e.g., sensor probes, diaphragms) resist chemical attack.

Materials: 316L SS, Hastelloy, PTFE, etc.

1.3 Pipeline and Installation Conditions

Pipe diameter: DN15 to DN1000+

Installation method: flanged, threaded, clamp-on, etc.

Flow velocity: affects flowmeter selection

Whether in-line maintenance is required (e.g., hot-tap installations).

2. Core Selection Criteria: Focus on Performance and Safety

2.1 Accuracy and Tolerance

Select accuracy level per process requirement:

Control-grade: 0.5%

Custody-transfer/Trade-grade: 0.1%

Consider installation-related and environmental errors: vibration, orientation, ambient temperature effects.

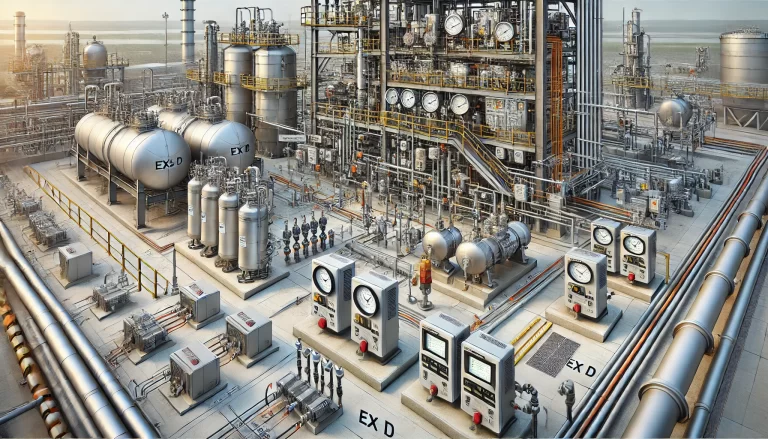

2.2 Environmental Adaptability and Protection

Explosion-proof compliance:

Most chemical plants fall under explosive atmospheres.

Ensure Ex certifications: China Ex, ATEX, IECEx

Ingress protection:

Wet, dusty, or corrosive environments need IP65+

Outdoor instruments require UV, rain, and surge protection.

Temperature and pressure rating:

High-temp (>300°C) → choose heat-resistant materials

Vacuum pipelines → confirm the device can withstand negative pressure.

2.3 Reliability and Maintenance

Favor simple, maintenance-free structures (e.g., electromagnetic flowmeters have no moving parts).

Check spare parts availability and lead time (some imported devices may have long delivery times).

Compare life cycle cost: initial price + maintenance + downtime risk.

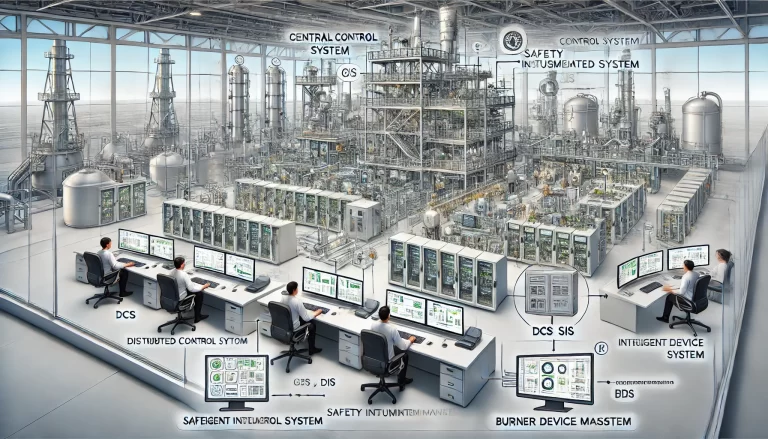

2.4 Signal Output and Communication

Match DCS/PLC requirements:

Analog: 4–20 mA, 0–10 V

Digital: HART, Modbus, Profibus

Smart instruments with LCDs and remote diagnostics enhance troubleshooting and visibility.

3. Typical Instrument Selection Scenarios

3.1 Flow Measurement

| Application | Recommended Instruments |

|---|---|

| Clean fluids | Turbine flowmeter (high accuracy), Electromagnetic (for conductive liquids), Vortex (steam/gas) |

| Corrosive media | Electromagnetic with PTFE lining, Positive displacement meter with Hastelloy body |

| Large pipes / low flow | Ultrasonic flowmeter (non-intrusive) |

| Slurry / solids | Target-type or wedge flowmeters (anti-blocking) |

3.2 Pressure Measurement

| Application | Recommended Instruments |

|---|---|

| General | Diffused silicon transmitter (cost-effective), Capacitive transmitter (high accuracy) |

| Corrosive / sticky media | Diaphragm-sealed transmitter (316L, Tantalum) |

| Hazardous area | Intrinsically safe transmitter (Ex ia) with safety barriers |

3.3 Temperature Measurement

| Application | Recommended Instruments |

|---|---|

| High temperature (>500°C) | Thermocouples (K, S type) with compensation cables |

| Medium/low temp | RTDs (PT100), better precision |

| Corrosive conditions | Armored RTD/TC with 316L or ceramic sheath |

| Non-contact | Infrared thermometer for molten or moving surfaces |

3.4 Level Measurement

| Application | Recommended Instruments |

|---|---|

| Open tanks | Magnetic level indicator, Submersible level transmitter |

| Pressurized vessels | Differential pressure (consider density), Radar level (non-contact, vapor-resistant) |

| Hazardous liquids | Servo-type level gauges (high accuracy, explosion-proof) |

4. Selection Pitfalls to Avoid

Avoid one-size-fits-all

Even within the same unit, different media may require different instruments.

Follow industry standards and certifications

Petrochemical: SH/T 3005, GB 50058

Food/Chemical: 3A, EHEDG hygienic certifications

Trial and Calibration Required

New instruments should undergo small-scale testing to validate stability and precision before mass deployment.

Balance cost and total value

Avoid chasing low price only. Consider lifecycle cost: instrument cost + maintenance + downtime loss.

5. Tools and Resources for Better Selection

Manufacturer catalogs and guides:

Global: E+H, Rosemount, Yokogawa

Local: Sichuan Instruments, Hongrun, etc.

Industry case studies:

Chemical forums, WeChat tech accounts for real-world application examples.

Software tools:

Some brands offer online calculators or configurators for flowrate, pressure drop, and model selection.

🔚 Conclusion

By following this structured approach and aligning technical specifications with process needs, chemical plant engineers can select instruments that offer precision, safety, and reliability. If you have a specific application (e.g., LPG flow measurement or sulfuric acid level monitoring), feel free to contact us for tailored suggestions.