1. Introduction

In process industries, liquid level is a typical integrating process variable, representing the physical balance of inflows and outflows in a vessel. Due to its integrating nature, level control loops often exhibit a unique set of challenges when applying conventional PID tuning methods—especially regarding the integral time.

One of the most common issues in liquid level PID control is sustained oscillation with constant amplitude and phase shift, often caused by using an integral time that is too short. Although it is well known that increasing the integral time can stabilize the loop, the key question remains: how much should it be increased?

2. Common Pitfalls in Level Control Tuning

In many industrial settings, simply tripling the integral time in response to oscillations only results in slower, but still persistent oscillations. In some early industry tuning guidelines, a recommended integral time of 300 seconds was suggested for large tanks. However, field experience often shows that even this is insufficient for true stability.

Why does this happen?

3. Understanding the Issue Through Lambda Tuning

Lambda tuning provides useful insight. According to the Lambda tuning formula for integrating processes:

Kp×Ti=4×λ

Where:

Kp is the proportional gain

Ti is the integral time

λ is the desired closed-loop time constant (larger for slower response)

In large tanks:

The process gain is small (due to the slow level change rate)

The dead time is usually short

As a result, Lambda tuning often recommends a high proportional gain and a short integral time

But in practice, operators often apply a low proportional gain to avoid overshoot and instability. This mismatch leads to a large effective Lambda, which in turn requires a much longer integral time than typically suggested.

4. The Challenge of Tuning Integrating Processes

Tuning integrating processes like level control via traditional step response testing can be time-consuming and error-prone. The process reaction is inherently slow, and drawing response curves is labor-intensive. A more operational and quantitative method is needed.

5. Introducing the Concept of Filling Time (T)

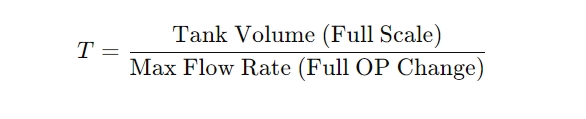

We propose a new practical metric to support PI tuning for level control: Filling Time, denoted as TTT.

Definition of Filling Time:

Where:

Tank volume corresponds to the full measurable range of the level transmitter

Max flow rate is the highest flow the control valve can achieve at 100% output

This value represents an equivalent time constant—the time it takes for the level to change 100% when the output changes from 0% to 100%. It is a straightforward calculation and eliminates the need for step testing.

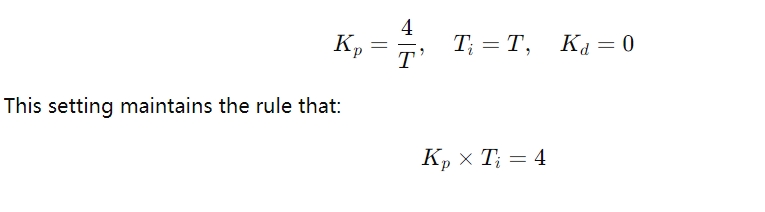

6. Recommended PI Parameters Based on Filling Time

Based on the Lambda tuning formula, we recommend:

Key Characteristics:

Higher Kp results in shorter Ti, offering stronger control action.

Lower Kp leads to longer Ti, ensuring stability for more sluggish systems.

This relationship provides a practical balance between responsiveness and stability, well-suited for the integrating nature of level processes.

7. Benefits of the Filling Time Method

✅ Avoids complex experimental step tests

✅ Simplifies PI tuning with calculable metrics

✅ Adapts naturally to system size and actuator capability

✅ Offers scalable tuning for both small vessels and large industrial tanks

8. Conclusion

Traditional tuning methods often fall short when applied to integrating processes like level control. By introducing the concept of Filling Time (T) and applying a simple rule (Kp=4/T, Ti=T), engineers can efficiently and reliably tune PI controllers without time-consuming experiments.

This method is especially valuable in large-scale systems where responsiveness is slow and process dynamics are dominated by integration effects.