Introduction

Even the most accurate load cell will fail to perform if it’s not mounted correctly.

In fact, improper installation is the #1 reason for unreliable, unstable, or inaccurate weighing system performance.

This article highlights the most common load cell mounting errors, their effects on measurement accuracy, and how to avoid or correct them.

1. Why Mounting Matters

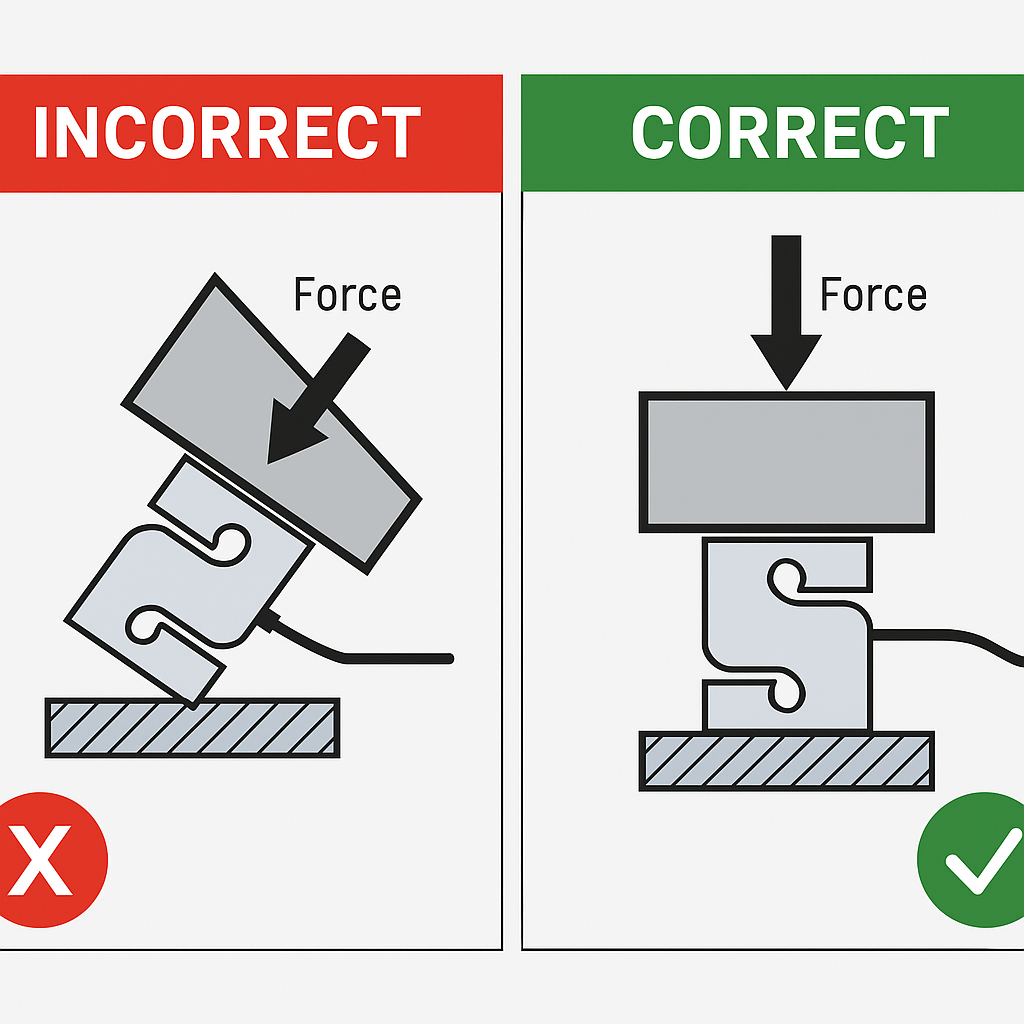

Load cells are designed to work under very specific loading conditions:

Axial force

No lateral or off-center load

Fixed and stable support surface

Any deviation can introduce errors far beyond the rated tolerance—sometimes more than 5–10 times the rated error limits.

2. Common Load Cell Mounting Errors

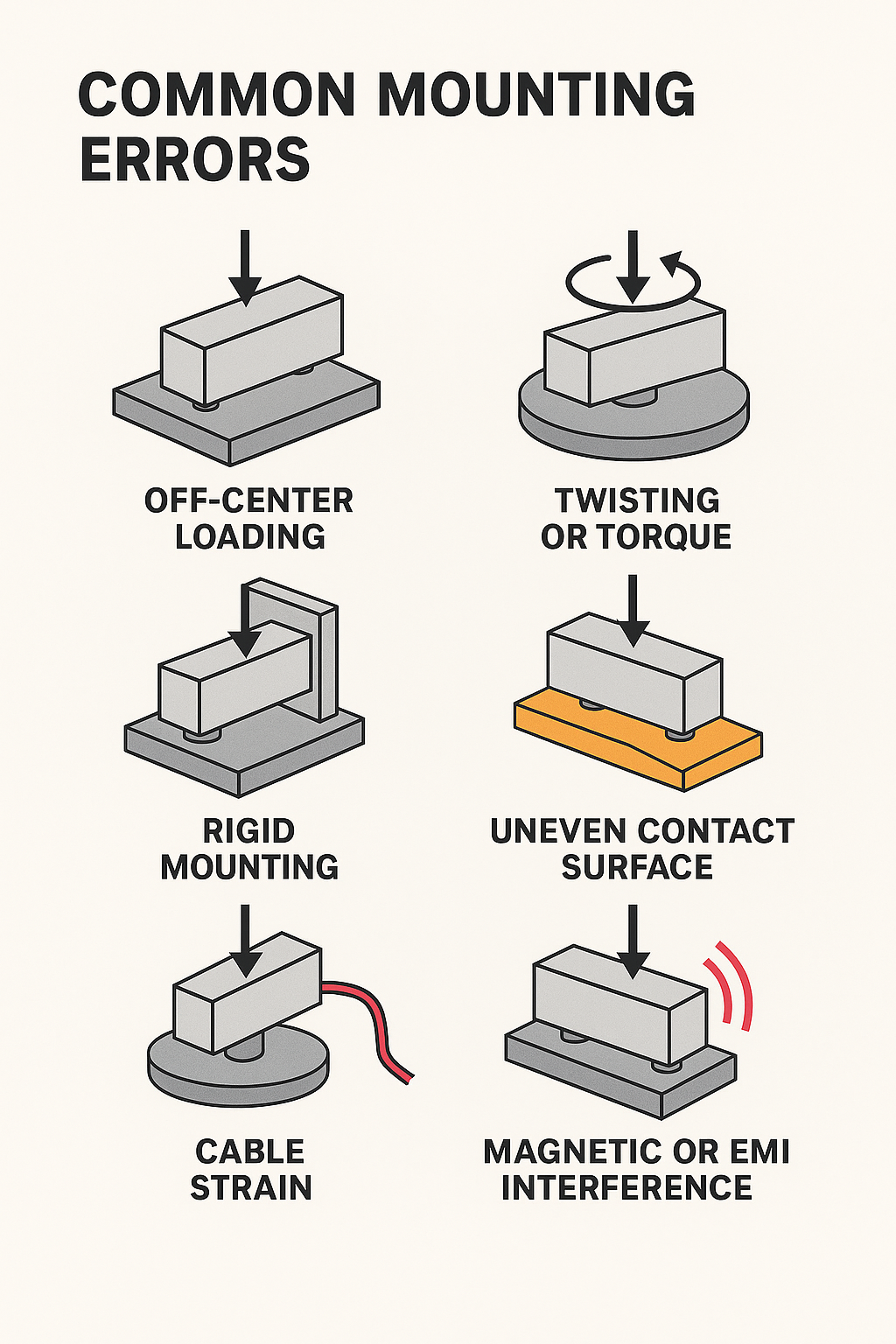

🔻 A. Off-Center Loading

The applied force doesn’t go through the load cell’s central axis.

Effect:

Uneven strain distribution

Readings become inconsistent and non-repeatable

May increase hysteresis and non-linearity

Fix:

Use load alignment fixtures or spherical washers

Employ guided load introduction platforms

⚙️ B. Twisting or Torque

Torque applied to the sensor via loading platform or misalignment.

Effect:

Structural distortion

Permanent mechanical damage or offset shift

Fix:

Use anti-twist mechanisms or decoupling mounts

Ensure free rotation or mechanical isolation

🧱 C. Rigid Mounting (No Floating Point)

Fixed mountings don’t allow natural expansion or contraction.

Effect:

Mechanical binding

Zero drift and instability with temperature

Fix:

Use manufacturer-recommended mounting kits

Allow horizontal freedom where needed (e.g., sliding bearings)

🔄 D. Uneven Contact Surface

Load cell not mounted on a flat, level, or clean base.

Effect:

Stress concentrations

Non-repeatable signals or early fatigue

Fix:

Always check surface flatness and use shims if necessary

Clean mounting area before installation

🔌 E. Cable Strain

Load cell cable is stretched, bent sharply, or tied too tightly.

Effect:

Signal interference or permanent damage

Moisture ingress or short circuits

Fix:

Use strain relief loops

Avoid cable pulls; route away from high-vibration areas

🧲 F. Magnetic or EMI Interference

Mounting near high-power cables or transformers

Effect:

Noisy signals, unstable output, or false triggering

Fix:

Route load cell cables separately

Use shielded cables and proper grounding

3. Symptoms of Improper Mounting

If you observe any of the following issues after installation, suspect a mounting problem:

| Symptom | Likely Cause |

|---|---|

| Fluctuating or unstable readings | EMI, cable strain, surface error |

| Inconsistent results between loads | Off-center force, mounting angle |

| No return to zero | Friction, thermal stress, binding |

| Drifting over time | Rigid mount, surface movement |

| High hysteresis or non-linearity | Torque or bending moment |

4. Best Practices for Load Cell Mounting

✅ Follow manufacturer’s mounting instructions

✅ Use alignment guides, spherical load buttons, or self-aligning feet

✅ Ensure load introduction is vertical and centered

✅ Use floating/flexible mounts for tanks or silos

✅ Isolate from vibrations, shocks, and lateral loads

✅ Always test and verify after installation (zero/load/release cycle)

5. Use Mounting Kits When Possible

Many load cell manufacturers offer dedicated mounting assemblies, such as:

Rocker pin or pendulum mounts

Compression mounts with centering rings

Tension adapters with rod ends or clevises

Using these kits:

Reduces installation errors

Improves repeatability

Increases safety and load alignment

Conclusion

Mounting is not just a mechanical task—it’s part of your measurement system.

Poor installation can turn a high-precision sensor into a source of failure.

By avoiding these common mistakes and using proper mounting strategies, you can ensure your load cell performs as specified for years to come.

🛠️ Good sensor, bad mount = bad results.

✅ Good sensor + good mount = trusted measurement.