1. Overview of Common Stainless Steels: 201, 202, 301, 304, 316

Common considerations for stainless steel selection include rust resistance, hardness, and processability. The corrosion and heat resistance, toughness, and durability typically increase in the order: 201 < 202 < 301 < 304 < 316.

Typical Parameters Comparison:

| Grade | Density (g/cm^3) | Thermal Conductivity (W/m.K @100°C) | Coefficient of Expansion (20–100°C, 10^-6/K) | Electrical Resistivity (Ω.mm^2/m @20°C) |

|---|---|---|---|---|

| 202 | 7.74 | 16.3 | 15.5 | 0.65 |

| 304 | 7.93 | 16.3 | 16.0 | 0.73 |

| 316 | 7.98 | 20.5 | 16.0 | 0.75 |

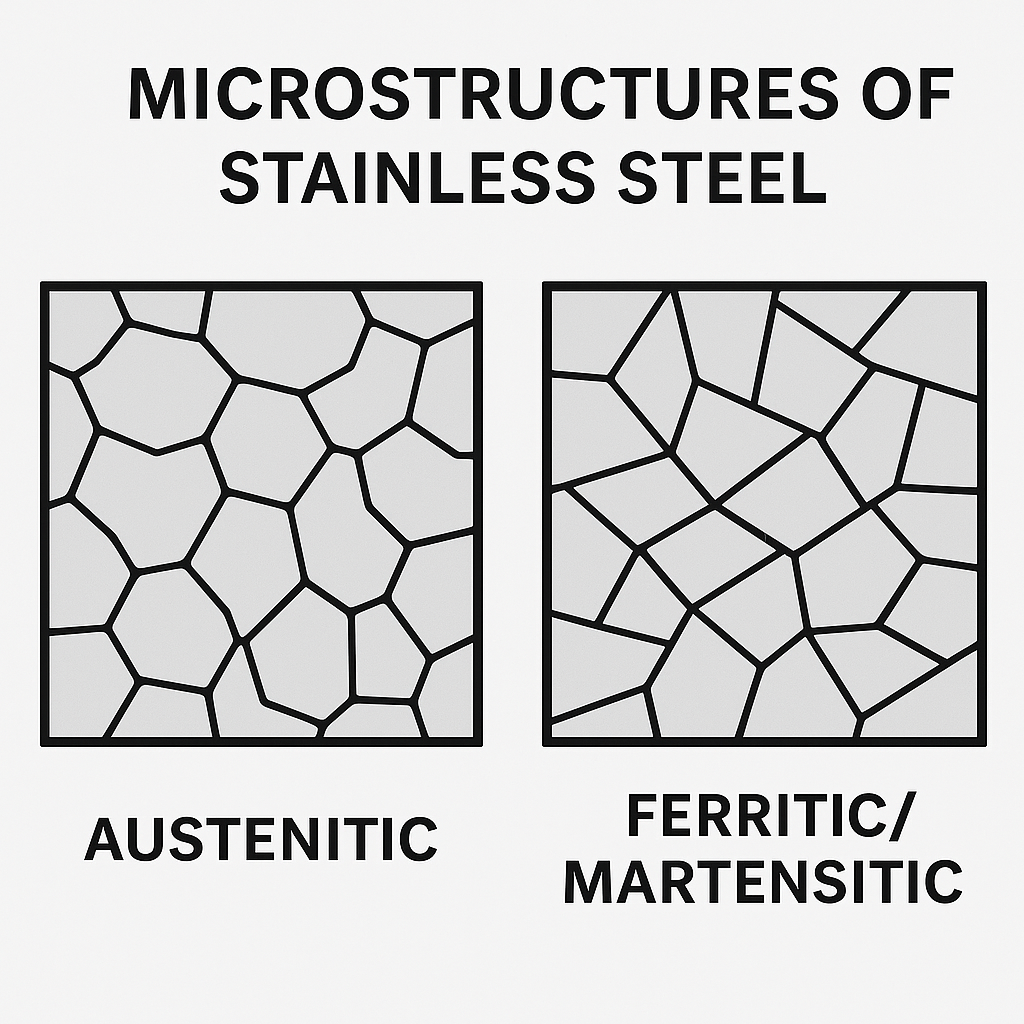

2. Grades, Composition, and Structure

Austenitic Stainless Steels: 200 & 300 series (e.g., 201, 304, 316)

Ferritic & Martensitic: 400 series (e.g., 410, 420, 430)

Notable Differences:

304 vs 316: 316 contains molybdenum, improving corrosion resistance in chloride environments.

201 vs 304: 201 has higher manganese, lower nickel, and worse corrosion resistance.

Magnetic Properties: Austenitic steels (304, 316) are generally non-magnetic but can acquire weak magnetism due to cold working.

3. Stainless Steels in Control Valves

| Grade | Key Properties | Application in Control Valves |

| 201 | Low cost, poor corrosion resistance, high hardness | Suitable for mild, indoor conditions, e.g., low-pressure clean water or air valves |

| 202 | Moderate corrosion resistance, better than 201 | Used in low corrosive environments, like auxiliary piping or basic food-grade applications |

| 301 | High strength, good corrosion and heat resistance | Often used for springs, valve stems, or medium-pressure steam valve parts |

| 304 | Excellent general-purpose corrosion resistance | Common in chemical, food, pharmaceutical, and gas valve components |

| 316 | Superior corrosion resistance, especially in chloride-rich environments | Ideal for marine, desalination, acid handling, and other harsh environments |

4. Extended Materials for Control Valve Construction

(A) Alloy Steels:

Cr-Mo Steels (e.g., 1Cr5Mo): For high-temperature/high-pressure use in petrochemical plants.

Cr-Mo-V Steels (e.g., ZG15Cr1Mo1V): Used in power generation and coal gasification valves.

(B) Copper Alloys:

Brass (H62, H68): Good mechanical and corrosion properties, used in freshwater or low-pressure systems.

Bronze (QSn4-3): Resistant to ammonia and seawater; used in marine systems and ammonia pipelines.

(C) Nickel Alloys:

Hastelloy C-276 / B-2: Excellent resistance to strong acids like HCl and H2SO4; used in chemical pipelines.

Inconel 625: High-temperature and high-corrosion resistance; used in aerospace and high-pressure steam systems.

(D) Non-Metallic Materials:

PTFE (Teflon): Exceptional chemical resistance; ideal for valve linings in pharma and precision chemical processes.

Ceramics (Alumina, Silicon Nitride): Extreme hardness and abrasion resistance; used in high-solids or erosive media valves.

5. Selection Summary Table

| Material | Recommended Applications |

| 304 SS | Food-grade, general chemical, HVAC valves |

| 316 SS | Marine, acidic chemical, pharmaceutical valves |

| Cr-Mo | High-temperature steam, catalytic cracking systems |

| Brass | Water supply, residential plumbing valves |

| Hastelloy | Phosphoric acid, hydrochloric acid valves |

| PTFE | Ultra-pure, corrosive media valve linings |

| Ceramics | High-abrasion, particulate-laden media valves |

Conclusion: Material selection for control valves must be based on specific process conditions including medium composition, temperature, pressure, and required lifecycle. Proper stainless steel or alloy selection ensures valve reliability, longevity, and safety in demanding industrial environments.