Vortex flow meters are widely adopted across multiple industries due to their rugged design, ability to handle steam and gas, and low maintenance needs. Unlike many other flow meter types, vortex meters can operate effectively under high temperature, high pressure, and challenging flow conditions, making them a popular choice for utility measurement and process control.

Here are the top 7 industrial sectors and scenarios where vortex flow meters are commonly used.

🏭 1. Steam Flow Measurement in Power Plants

Why it’s ideal:

Vortex meters can withstand the high temperatures and pressures typical in saturated and superheated steam systems. They offer accurate mass or volumetric flow readings for energy monitoring, boiler control, and turbine feed.

Key features:

High-temperature resistance (up to 400°C)

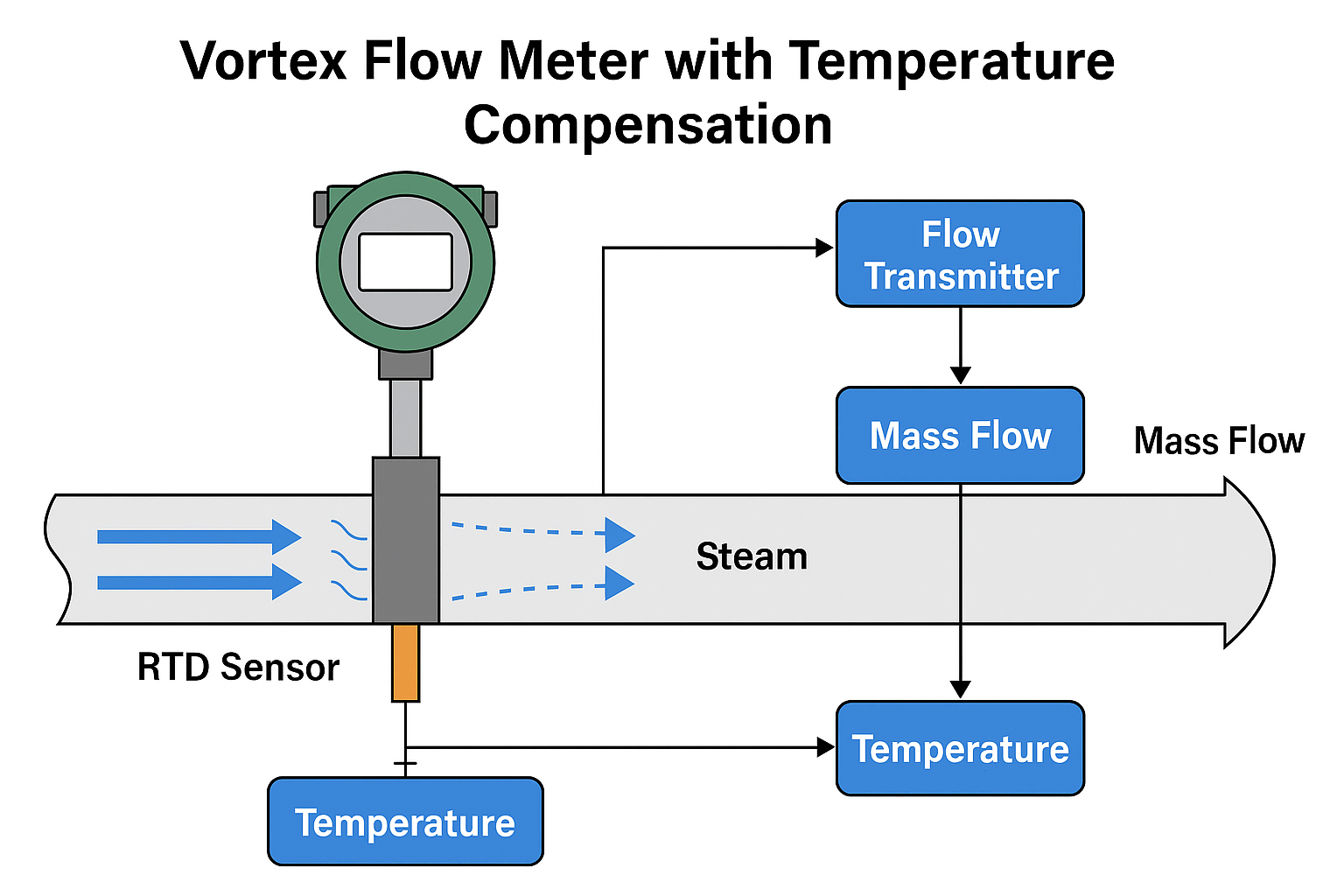

Optional temperature compensation

No moving parts, long-term reliability

⚗️ 2. Process Steam Monitoring in Chemical Plants

Application:

Used for process heating, sterilization, and distillation.

Advantages:

Handles corrosive or reactive media with stainless steel body

Supports digital protocols (Modbus, HART) for DCS integration

Excellent repeatability for consistent process control

🧺 3. HVAC & District Heating Systems

Usage:

Measuring steam or hot water flow in building-level or municipal heating systems.

Why vortex works well:

Compact design

Built-in totalizer for energy billing

Good performance with clean liquids or steam

🥫 4. Food and Beverage Industry – Clean Utilities

Application Areas:

CIP (Clean-in-Place) steam

Utility gases (CO₂, N₂)

Process water

Preferred features:

Sanitary or hygienic flange options

Easy-to-clean structure

High repeatability during batch operations

🏗️ 5. Compressed Air and Industrial Gases

Application:

Compressed air flow metering in pneumatic systems, nitrogen flow monitoring in inerting systems, etc.

Why vortex meters are used:

No drift due to sensor wear

Handles wide range of flow rates

Can integrate with energy management platforms

🧪 6. Pharmaceutical and Biotech Plants

Common use:

Pure steam and WFI (Water for Injection) systems require precise, sterile flow metering.

Why suitable:

Hygienic-grade vortex meters available

Suitable for clean steam at high purity

Integration with batch records and validation systems

🛢️ 7. Oil & Gas and Petrochemical Industry

Application Examples:

Fuel gas metering

Utility steam monitoring

Hydrogen or flare gas measurement (with caution)

Special needs met:

Explosion-proof design

Stainless steel or Hastelloy body options

High-pressure tolerance

✅ Summary Table: Where Vortex Flow Meters Excel

| Industry | Measured Media | Why Vortex is Suitable |

|---|---|---|

| Power Generation | Saturated/Superheated Steam | High temp resistance, mass flow capability |

| Chemical | Steam, gases | Corrosion resistance, stable output |

| HVAC/District Energy | Steam, hot water | Energy metering, easy installation |

| Food & Beverage | Steam, CO₂, water | Cleanable, reliable in utilities |

| Industrial Gases | Compressed air, nitrogen | No drift, fast response |

| Pharma & Biotech | Clean steam | Sanitary design, high accuracy |

| Petrochemical | Fuel gas, steam | Explosion-proof, rugged |

📌 Conclusion

Vortex flow meters offer a versatile and durable solution for flow measurement across multiple industries. With proper selection—especially considering media type, temperature, and installation constraints—they provide years of accurate, stable, and low-maintenance service in critical flow applications.