In the evolving world of industrial automation, Model Predictive Control (MPC) is often positioned as the future of process control—boasting advanced features like constraint handling, multi-variable coordination, and performance optimization. But will MPC replace the time-tested PID (Proportional-Integral-Derivative) controller, which has dominated the industry for nearly a century?

From a conservative engineering perspective, the answer is far more nuanced than a simple yes or no.

🔍 What Does Conservatism Mean in Engineering?

Conservatism, in this context, is not about rejecting innovation. It means:

Prioritizing stability over novelty

Trusting tools with proven track records

Favoring gradual evolution over radical overhaul

Seeking transparency, simplicity, and reliability

These principles influence decision-making in control systems, especially in safety-critical industries like chemical processing, energy, and pharmaceuticals.

✅ Why PID Remains the Industry Standard

PID control continues to dominate because it perfectly aligns with conservative engineering values:

| Feature | PID Advantage |

|---|---|

| Simplicity | Easy to understand, tune, and explain |

| Universality | Applicable to 80%+ of industrial loops |

| Low Cost | Minimal hardware/software requirements |

| Robustness | Tolerates noise, delay, and modeling errors |

| Operator Acceptance | Widely understood by technicians and engineers |

| Standardization | Integrated into industrial standards, certifications, and training |

In short, PID is the default control strategy, not because it’s perfect—but because it’s good enough for most tasks, and safe to trust.

🚀 The Promise and Pitfalls of MPC

MPC is undeniably powerful. It uses a dynamic model of the process to predict future behavior and optimize control moves accordingly. Its strengths are clear:

Handles multi-variable interactions

Manages hard constraints on inputs and outputs

Enables energy savings and quality improvements

Supports predictive operations in smart factories

But from a conservative lens, MPC also has critical limitations:

| Concern | Conservative Viewpoint |

|---|---|

| Complexity | Difficult to understand and explain; “black-box” behavior |

| Model Dependency | Sensitive to modeling errors; requires expert calibration |

| Computational Demand | Needs high-performance hardware or cloud infrastructure |

| Maintenance Burden | Requires skilled personnel for updates and troubleshooting |

| Training Gap | Operators and engineers often lack MPC-specific knowledge |

| Vendor Lock-in | Proprietary platforms may limit long-term flexibility |

In essence, MPC can deliver optimal performance—but only if all conditions are met. That’s a high bar in real-world environments.

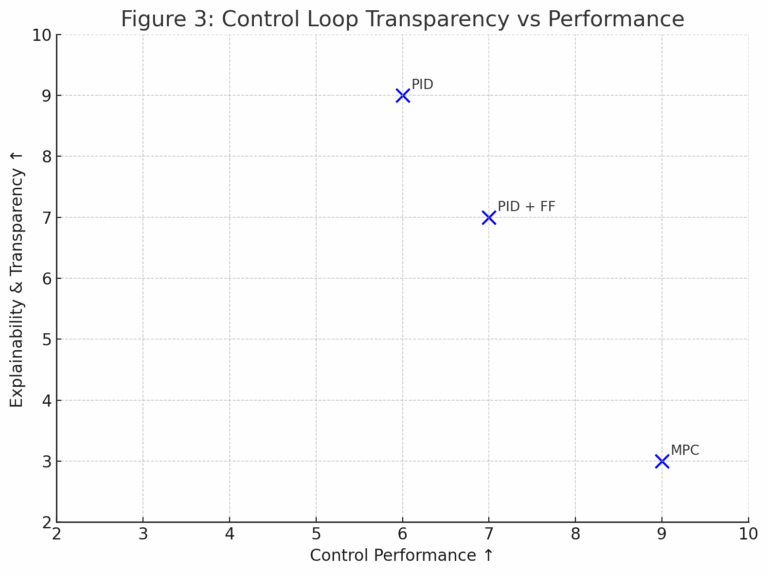

🆚 MPC vs PID: A Conservative Comparison

| Criteria | PID | MPC |

|---|---|---|

| Required Process Knowledge | Low | High (accurate modeling essential) |

| Operator Acceptance | Very high | Low to moderate |

| Transparency & Debuggability | High | Low |

| Implementation Cost | Low | High |

| Maintenance Requirement | Minimal | Frequent tuning and validation |

| Regulatory & Safety Certification | Mature & standardized | Limited and application-specific |

🧭 The Conservative Forecast: Coexistence, Not Replacement

From a conservative perspective, MPC will not replace PID—it will supplement and complement it.

PID will remain the default for simple, robust, fast-response control loops (temperature, flow, pressure).

MPC will grow in niche applications: advanced process control (APC), energy-intensive systems, chemical reactors, distillation columns, etc.

The future lies in hybrid architectures:

MPC handles optimization at supervisory level

PID executes inner-loop stabilization

This layered approach aligns with conservative values—retain what works, add what improves.

🛠️ Engineering Recommendations

| Industrial Scenario | Conservative Suggestion |

|---|---|

| Legacy plants with limited budgets | Stick to PID; consider optimizing tuning |

| New smart factories | Plan MPC deployment with proper modeling and training |

| Energy- or quality-sensitive lines | Use MPC for outer-loop optimization |

| Regulatory-sensitive environments | Prefer PID unless MPC is certified |

🔚 Conclusion

MPC is not a revolution—it is an evolution. From a conservative engineering standpoint, the goal is not to discard PID, but to carefully and selectively deploy MPC where it delivers clear, measurable benefits without sacrificing reliability or transparency.

Technological innovation should serve the system—not the other way around.