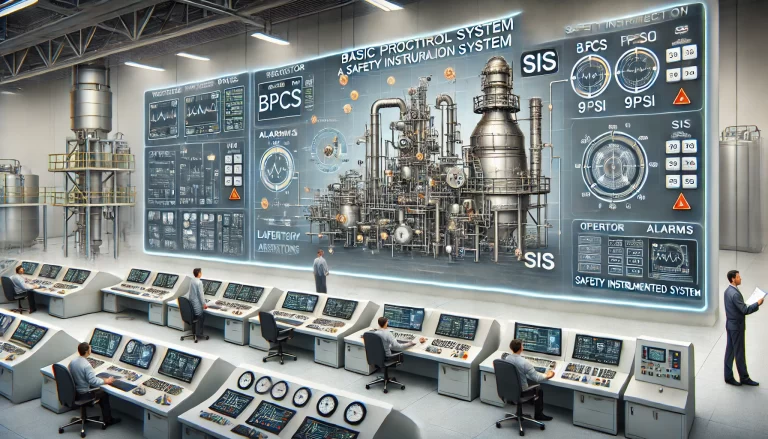

This article examines whether Safety Instrumented Systems (SIS) are required for Level-3 major hazard sources involving liquefied gases. The analysis is based on Chinese regulations, industry standards, and risk assessment methodologies. We explore key conditions under which SIS becomes necessary, especially for hazardous chemicals such as LNG, LPG, and liquid ammonia.

1. Regulatory and Standard-Based Framework

In China, the determination of whether a SIS is required is guided by a combination of national regulations and technical standards:

Regulation Reference:

The Interim Provisions on the Supervision and Administration of Major Hazard Installations of Hazardous Chemicals (Order No. 40 of SAWS) requires that enterprises take appropriate safety measures based on the risk level of the hazard source. However, it does not explicitly mandate SIS installation.Guideline Reference:

The Guiding Opinions on Strengthening the Management of Safety Instrumented Systems in Chemical Industry (SAWS Doc No. [2014]116) clearly states that installations involving any of the “Two Key and One Major” (i.e., key hazardous processes, key hazardous chemicals, and major hazard sources) must determine the need for SIS and its SIL level through formal safety evaluations.

2. Specific Risks Associated with Liquefied Gases

Risk Level Definition

Major hazard sources are categorized into four levels:

Level 1: Extremely high risk

Level 2: High risk

Level 3: Medium-high risk

Level 4: Low risk

Level-3 represents a significant safety concern, especially when involving liquefied gases.

Characteristics of Liquefied Gases

Liquefied gases such as LNG, LPG, and liquid ammonia are:

Highly flammable or explosive

Stored under high pressure or extremely low temperatures

Prone to catastrophic consequences if leakage or ignition occurs

These properties often require automated emergency shutdown (ESD) and interlock protection through a SIS.

3. Core Criteria for SIS Implementation

The decision to implement SIS hinges primarily on two aspects:

1) Risk Assessment Results

Using HAZOP (Hazard and Operability Study) and LOPA (Layer of Protection Analysis), determine whether existing protection layers (e.g., alarms, DCS, mechanical relief) can reduce residual risk to an acceptable level.

If not, SIS must be installed, and its Safety Integrity Level (SIL) must be defined.

2) Local Regulatory Requirements

In regions such as Jiangsu, Shandong, and other industrial provinces, local emergency authorities may impose stricter requirements on SIS implementation for Level-3 or above hazard sources. Local compliance must be confirmed before project execution.

Important: While national laws do not explicitly require SIS for all Level-3 hazard sources, liquefied gas installations often fall into scenarios where SIL assessment leads to SIS configuration in practice.

4. Practical Recommendations

To ensure both safety and regulatory compliance, the following steps are recommended:

| Step | Action | Description |

|---|---|---|

| ① | Conduct HAZOP/LOPA Analysis | Engage certified professionals to assess process risks and determine SIS needs and SIL levels. |

| ② | Consult with Local Authorities | Early communication with local emergency departments helps clarify expectations and avoid compliance delays. |

| ③ | Design Compliant SIS | If SIL1 or above is required, design, implement, and validate the SIS in accordance with GB/T 37243 and IEC standards. |

Conclusion

While SIS is not universally mandated for all Level-3 major hazard sources under Chinese law, liquefied gas facilities are high-risk scenarios where SIS is frequently required based on risk assessment results.

Enterprises should prioritize engineering evaluations and regulatory consultation to determine SIS requirements and ensure legal and operational safety.