Understanding the Root Causes and How to Prevent Them

1. Background: A Common Yet Costly Problem

Many industrial users—especially in chemical plants—have reported frequent failures with corrosion-resistant probes from various brands. Despite switching suppliers, the coating on the sensor heads often peels off within a few months, leading to corrosion and sensor malfunction.

Instrumentation in harsh environments such as petrochemical plants, power stations, mines, and offshore platforms must endure extreme temperatures, pressures, and corrosive media. The thin layer of coating on a probe is often the first and only line of defense—and the most common point of failure.

2. What Are Functional Coatings?

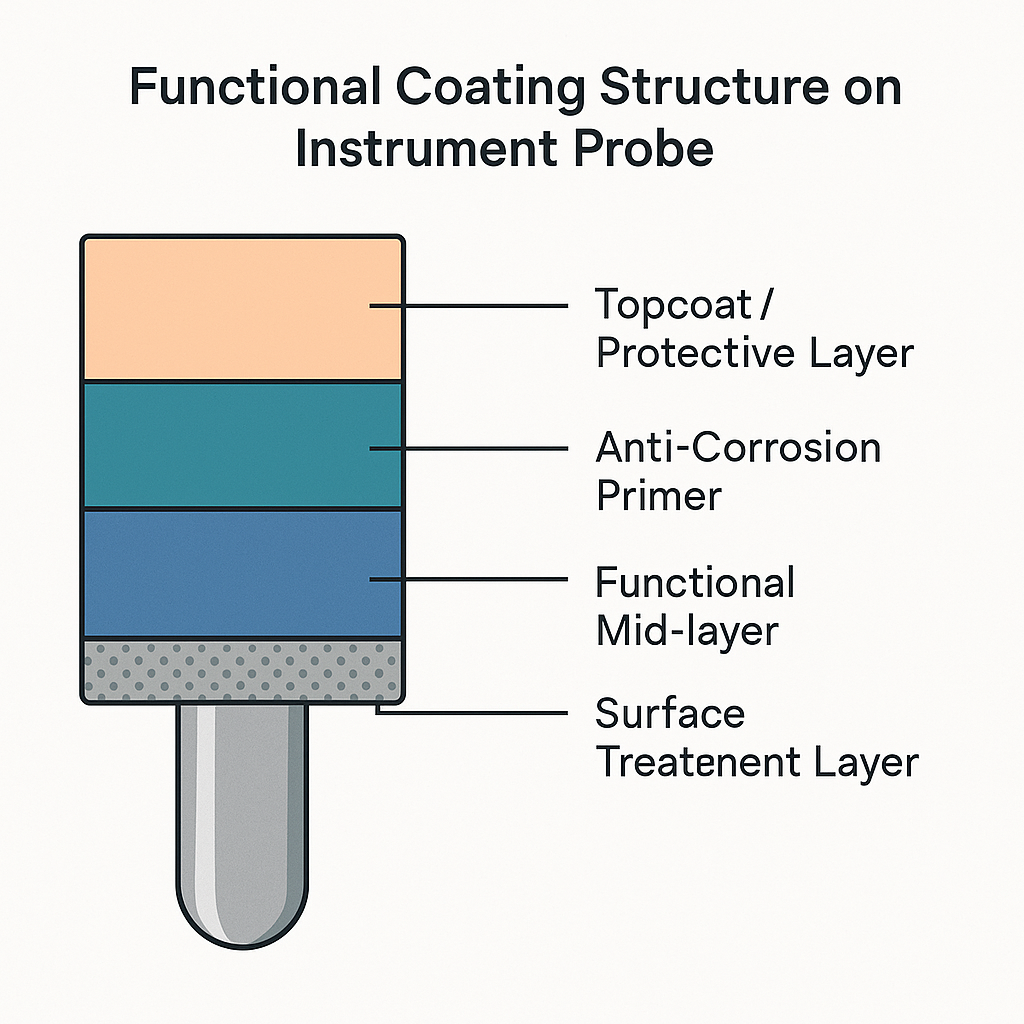

Unlike traditional paint used for decoration or basic rust prevention, modern sensor coatings are engineered multi-layer functional systems. Key types include:

▸ Anti-Corrosion Coatings

Designed to block water, salt, acids, and alkalis—like a raincoat for the sensor. Typical systems include zinc-rich epoxy primers and fluorocarbon or polyurethane topcoats. Advanced systems even include sacrificial zinc layers to mitigate corrosion.

▸ High-Temperature Resistant Coatings

Materials like polyimide, ceramics, and hybrid composites that withstand extreme heat without softening or degrading. Their high glass transition temperature (Tg) makes them suitable for environments like boilers and engines.

▸ Wear-Resistant & Self-Lubricating Coatings

Used on moving parts or valve connections. These coatings contain PTFE or MoS₂ particles to reduce friction and extend service life.

▸ Superhydrophobic / Anti-Condensation Coatings

Vital for radar and ultrasonic level sensors, these coatings use nano-structured surfaces to repel water droplets and dirt, preventing signal interference.

▸ Anti-Static / EMI Shielding Coatings

Essential for explosion-proof or high-precision environments. Coatings are filled with conductive polymers, carbon nanotubes, or metal particles to suppress electrostatic discharge and electromagnetic noise.

▸ Self-Healing Coatings

Used in high-end sensors. Embedded microcapsules release healing agents when microcracks occur, extending the lifetime of the coating under harsh conditions.

3. Why Do Coatings Fail Under High Temperature?

Many assume that coating failures stem from poor application or cheap materials. However, thermal stress is often the root cause:

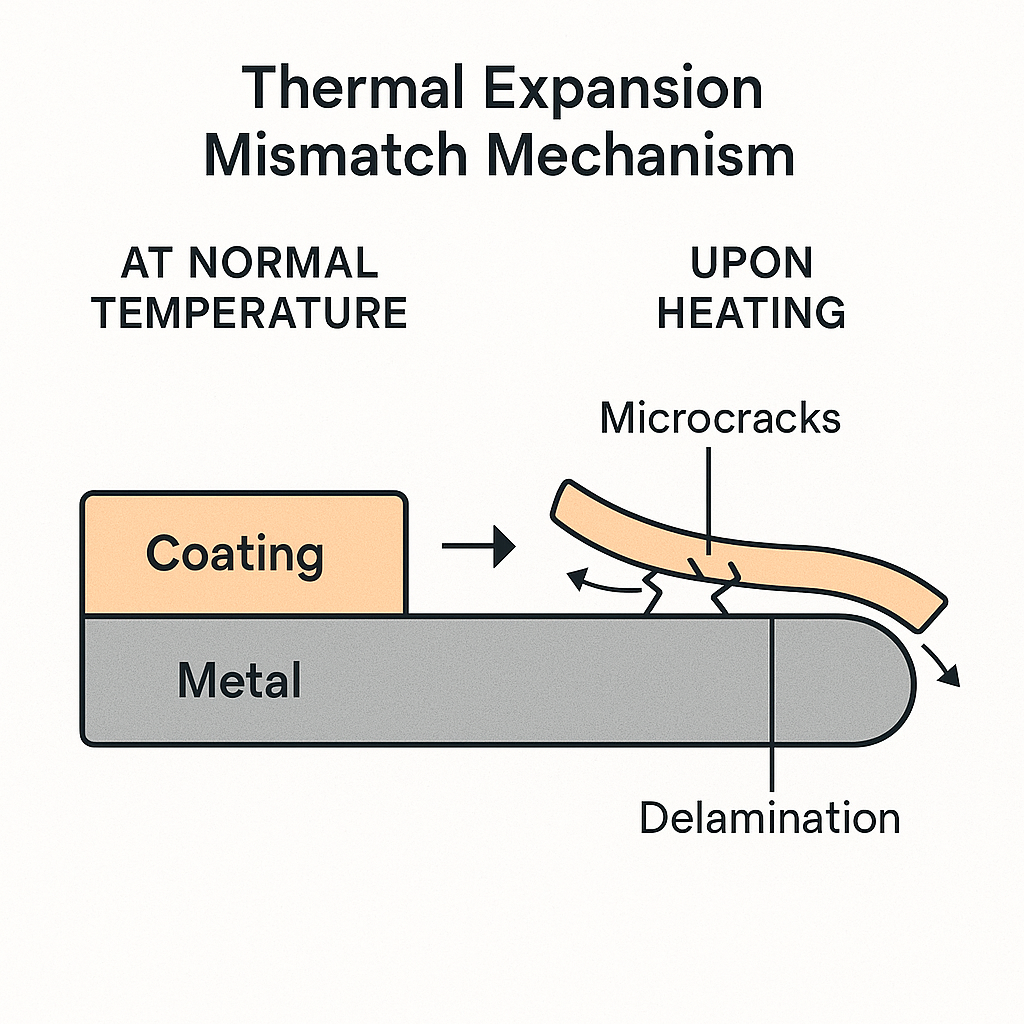

▸ Thermal Expansion Mismatch

Sensors and coatings have different expansion coefficients. Repeated heating and cooling causes microcracks, which expand over time and eventually lead to delamination.

▸ Chemical Degradation

Most polymers degrade under high heat. For example, epoxy resin loses tensile strength beyond its Tg, causing discoloration, powdering, and peeling.

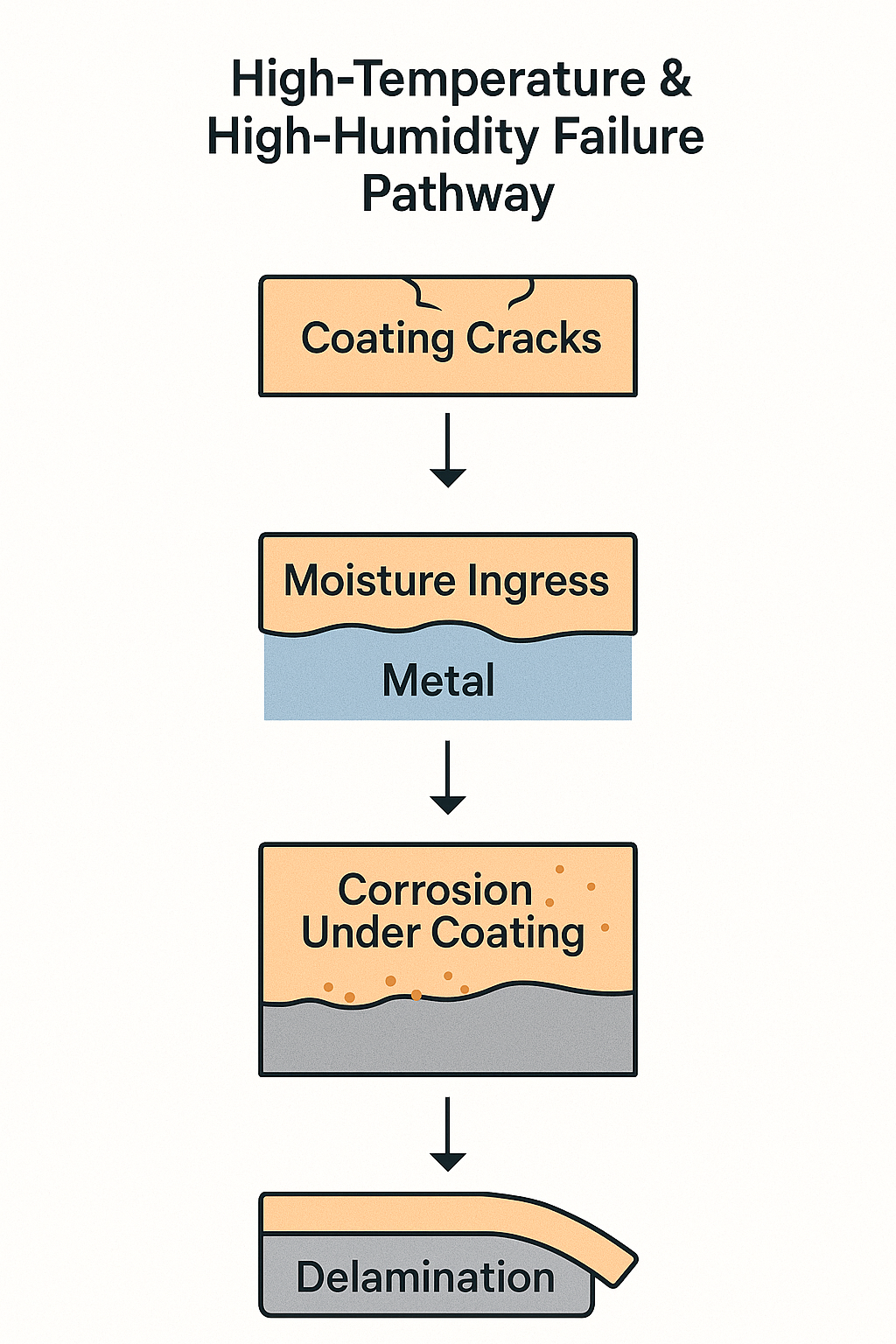

▸ Accelerated Moisture Ingress

Heat enlarges coating micropores, making it easier for moisture and ions to penetrate and initiate corrosion beneath the coating.

▸ Design & Layer Compatibility

Multi-layer coatings require thermal compatibility between layers. Poor material selection or surface preparation often leads to premature failure.

4. Low-Pressure Environments: A Hidden Threat

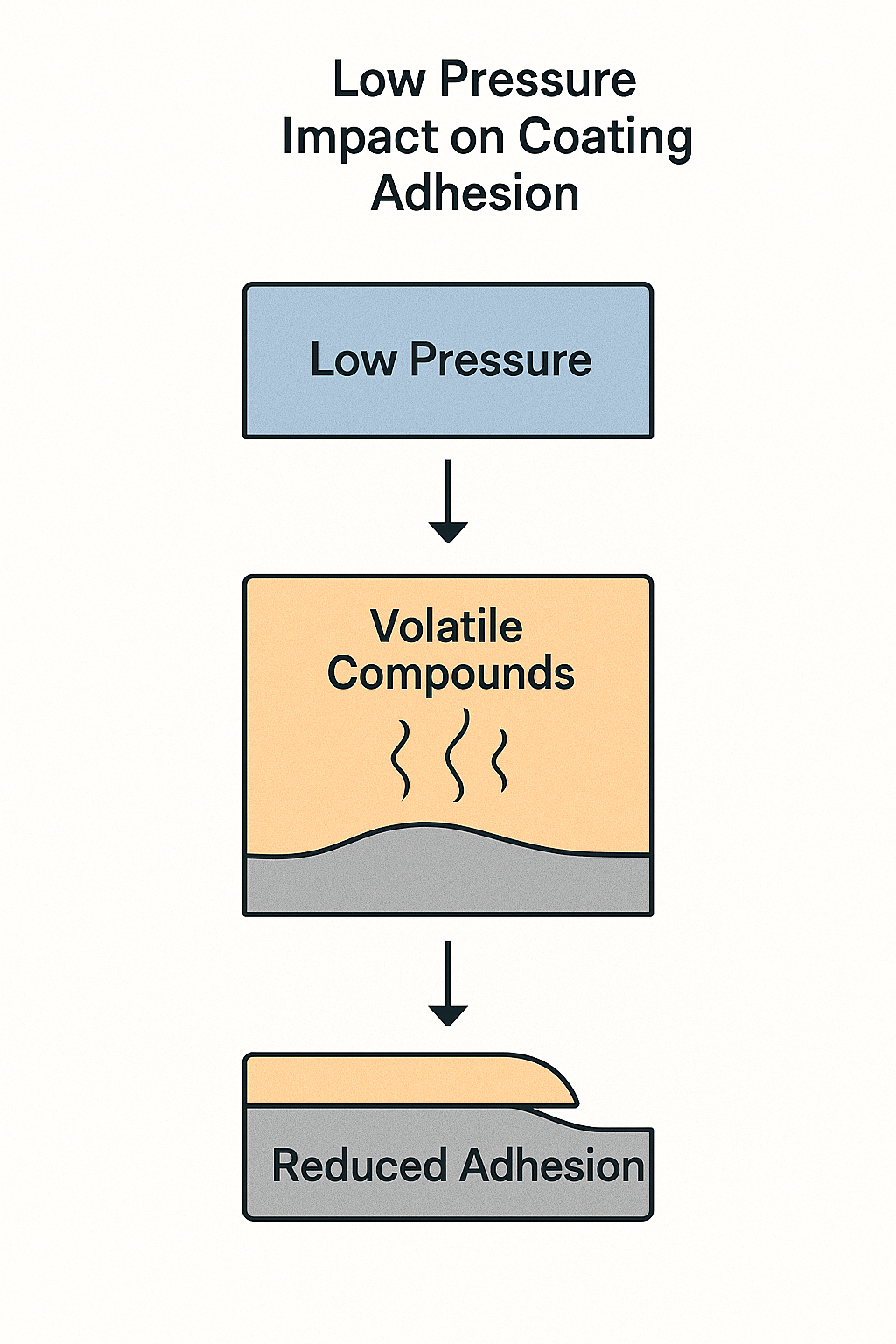

Low-pressure environments (e.g., high altitudes, vacuum chambers) can silently undermine coating integrity:

▸ Accelerated Volatile Loss

Solvents or unreacted components in the coating may evaporate quickly under low pressure, forming micropores and reducing adhesion.

▸ Interface Delamination

Vacuum conditions weaken molecular bonding. Coatings reliant on micro-anchoring lose adhesion, much like a suction cup losing grip.

▸ Electrostatic Accumulation

Low pressure inhibits discharge of static electricity, especially in polymer materials. This may lead to micro-sparking or fatigue cracks.

▸ Countermeasures

Use highly cross-linked, low-volatility materials. Pre-treat surfaces with plasma activation, vacuum baking, or ultrasonic cleaning to improve adhesion.

5. Real-World Case Studies

Thermal Delamination in a Coastal Power Plant: A high-temp epoxy coating failed within 6 months due to poor surface prep and salt fog exposure. Replacing with a “better paint” didn’t help—systemic process flaws were the real issue.

Sensor Failure in High-Altitude Applications: Bubbles and peeling due to poor curing and solvent evaporation under low pressure. Solved by process and material improvements.

Static Discharge in Oilfield Sensors: Improper selection of anti-static coating led to partial flashover and sensor damage under high-temp + low-pressure coupling.

6. How to Prevent Coating Failures

✔ Correct Material Selection

Match the coating to the operating environment—high Tg for heat, dense cross-linked layers for vacuum.

✔ Rigorous Surface Treatment

Include sandblasting, acid pickling, plasma activation, or ultrasonic cleaning before application.

✔ Multi-Functional Layer Design

Use layered coatings with distinct roles: base for adhesion, middle for thermal or anti-corrosion, top for anti-fouling or anti-static.

✔ Field Usage and Maintenance Control

Avoid harsh mechanical impact or chemical cleaning. Train maintenance staff on proper care procedures.

✔ Simulated Environment Testing

Lab test under combined high temp, humidity, vacuum, and salt spray conditions to anticipate failures.

7. Final Thoughts

The issue of sensor coating delamination is a classic “weakest link” problem. No single magical material can solve all challenges. A robust solution requires:

Systematic thinking across materials, processes, and use environments

Strict process control and surface preparation

Real-world testing and preventive design

Only by treating coating durability as a system-level engineering problem—not just a materials issue—can long-term reliability be achieved.