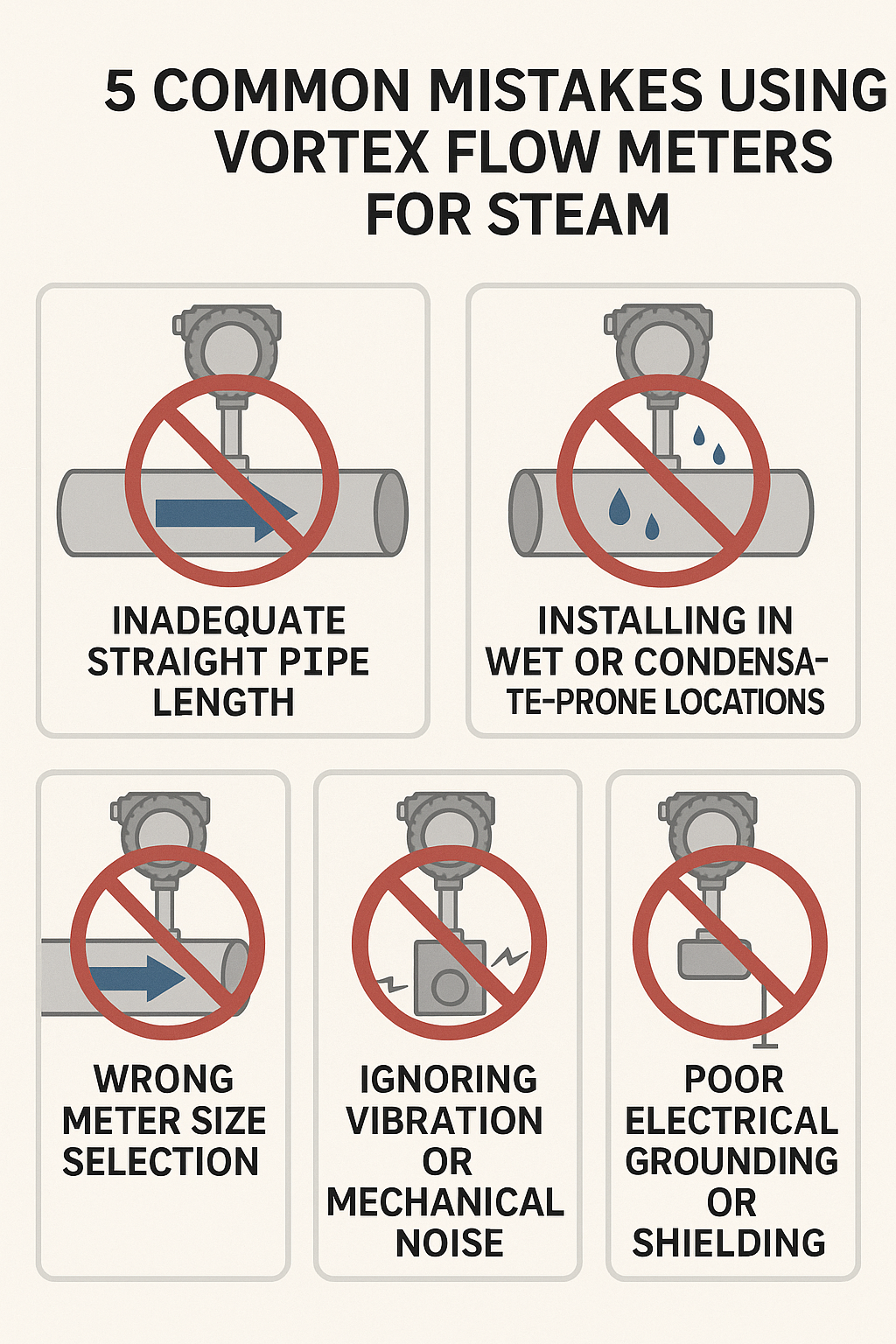

Vortex flow meters are popular for measuring steam due to their durability and suitability for high-temperature and high-pressure conditions. However, improper installation or misuse can lead to significant accuracy issues, system failures, or long-term reliability problems. This article outlines the top 5 mistakes engineers and technicians often make—and how to avoid them.

❌ Mistake 1: Inadequate Straight Pipe Length

Why it matters:

Vortex shedding requires a stable, fully developed flow profile. If elbows, valves, or reducers are too close to the meter, flow turbulence can lead to erratic readings or signal loss.

Solution:

Ensure minimum straight-run piping:

Upstream: ≥ 15–25 × DN

Downstream: ≥ 5 × DN

Use flow straighteners if space is limited.

📌 Tip: DN refers to nominal pipe diameter.

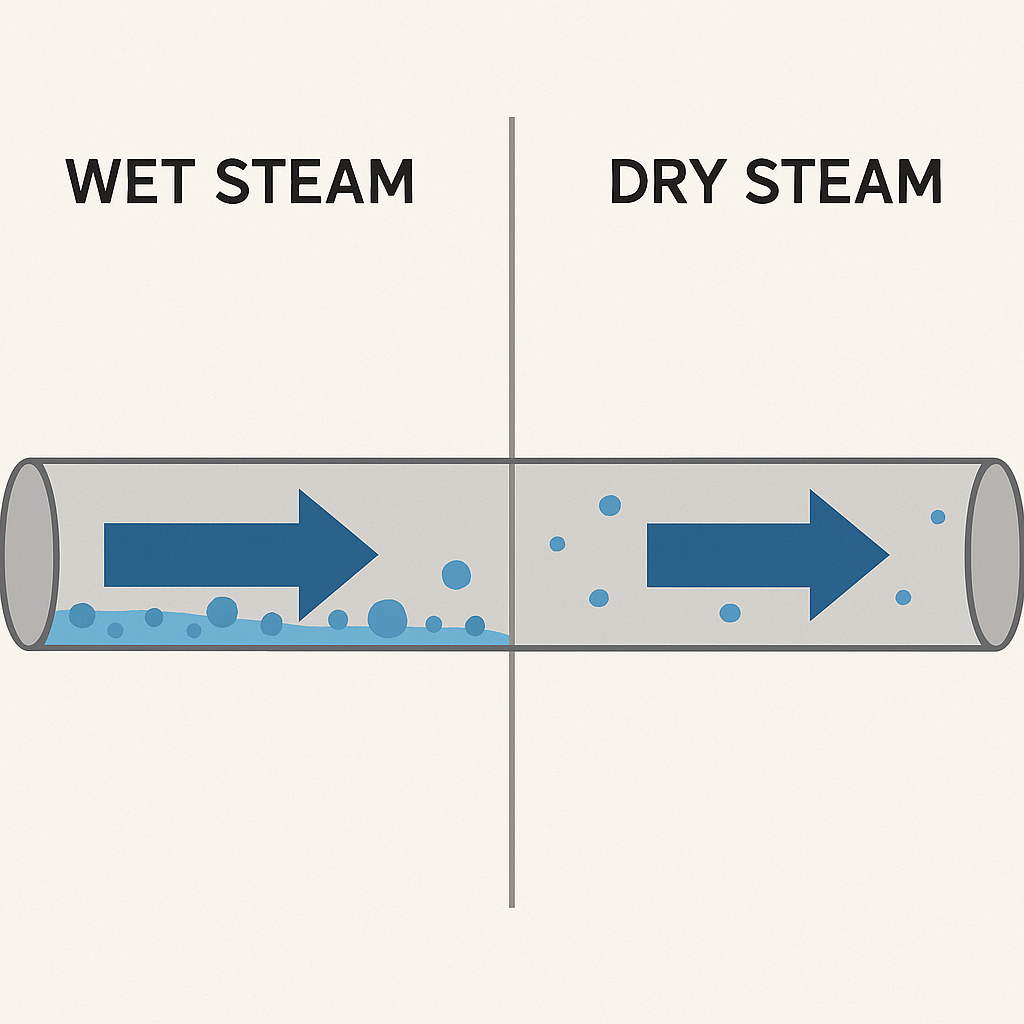

❌ Mistake 2: Installing in Wet or Condensate-Prone Locations

Why it matters:

Condensate droplets can cause noise, false vortex detection, or sensor damage. Accumulated liquid can also block the vortex path or corrode components.

Solution:

Install steam traps and drip legs upstream.

Use horizontal mounting with the sensor above the pipe centerline.

Avoid low points or pipe sag areas.

🧠 Insight: Wet steam = unstable signal. Dry steam = stable measurement.

❌ Mistake 3: Wrong Meter Size Selection

Why it matters:

Oversized meters may not generate sufficient vortex signals at low flows. Undersized meters may experience excessive pressure drop or vibration.

Solution:

Match meter size to actual flow range, not just pipe size.

Use manufacturer sizing charts or consult application engineers.

📊 Example: For DN80 saturated steam line, flow should be within 500–5000 kg/h for accurate measurement.

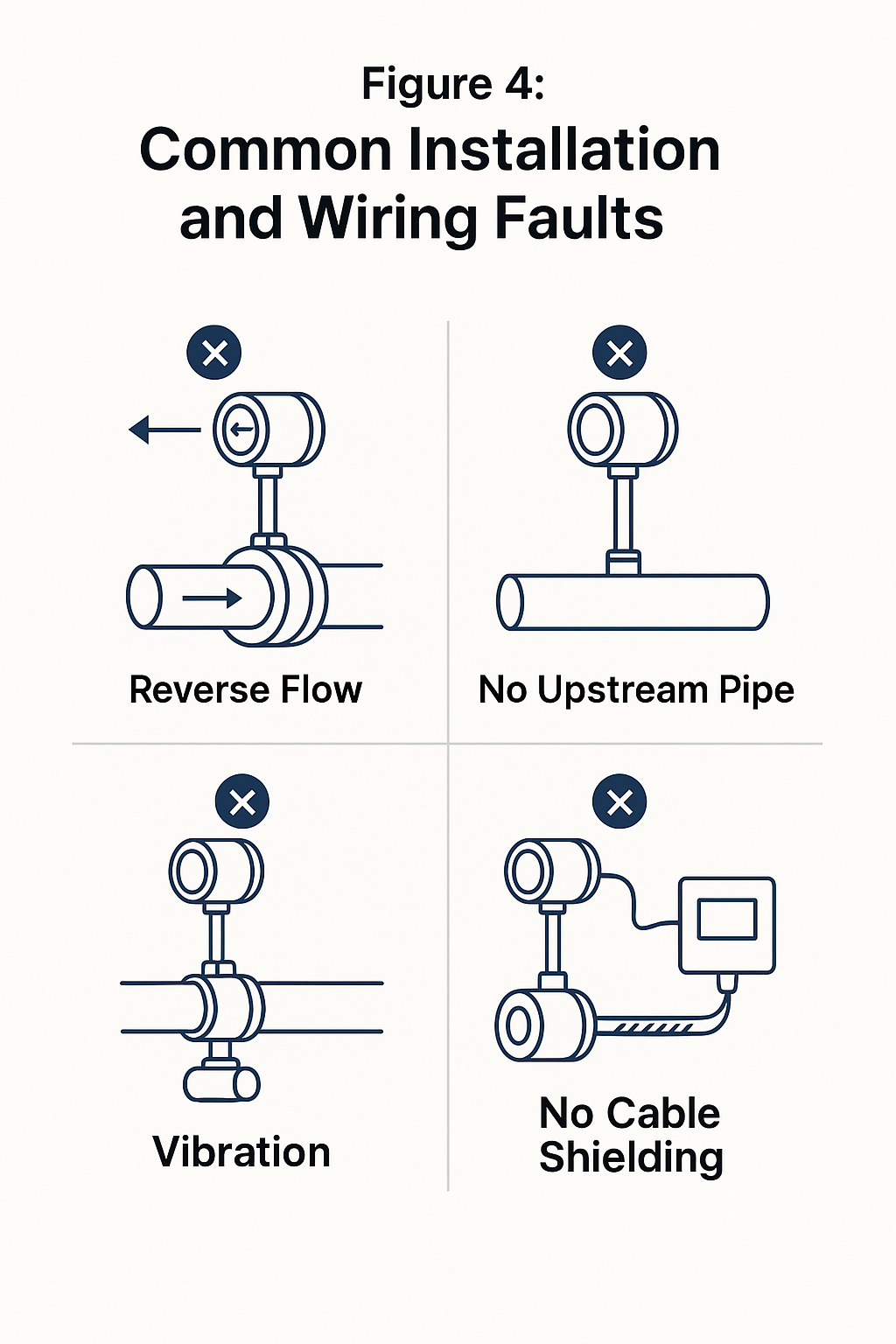

❌ Mistake 4: Ignoring Vibration or Mechanical Noise

Why it matters:

Excessive pipe vibration can interfere with vortex frequency detection, leading to false counts or unstable signals.

Solution:

Avoid installation near pumps, compressors, or heavy-duty valves.

Use support brackets to reduce vibration.

Choose meters with anti-vibration design if needed.

🎯 Tip: Vibration is a leading hidden cause of flow signal instability.

❌ Mistake 5: Poor Electrical Grounding or Shielding

Why it matters:

Steam environments often have strong EMI (electromagnetic interference) from motors or relays, which can corrupt signal transmission.

Solution:

Use shielded signal cables.

Ground both the meter body and shield properly.

Keep control wiring away from power cables.

🔌 Note: Always follow manufacturer’s wiring diagram.

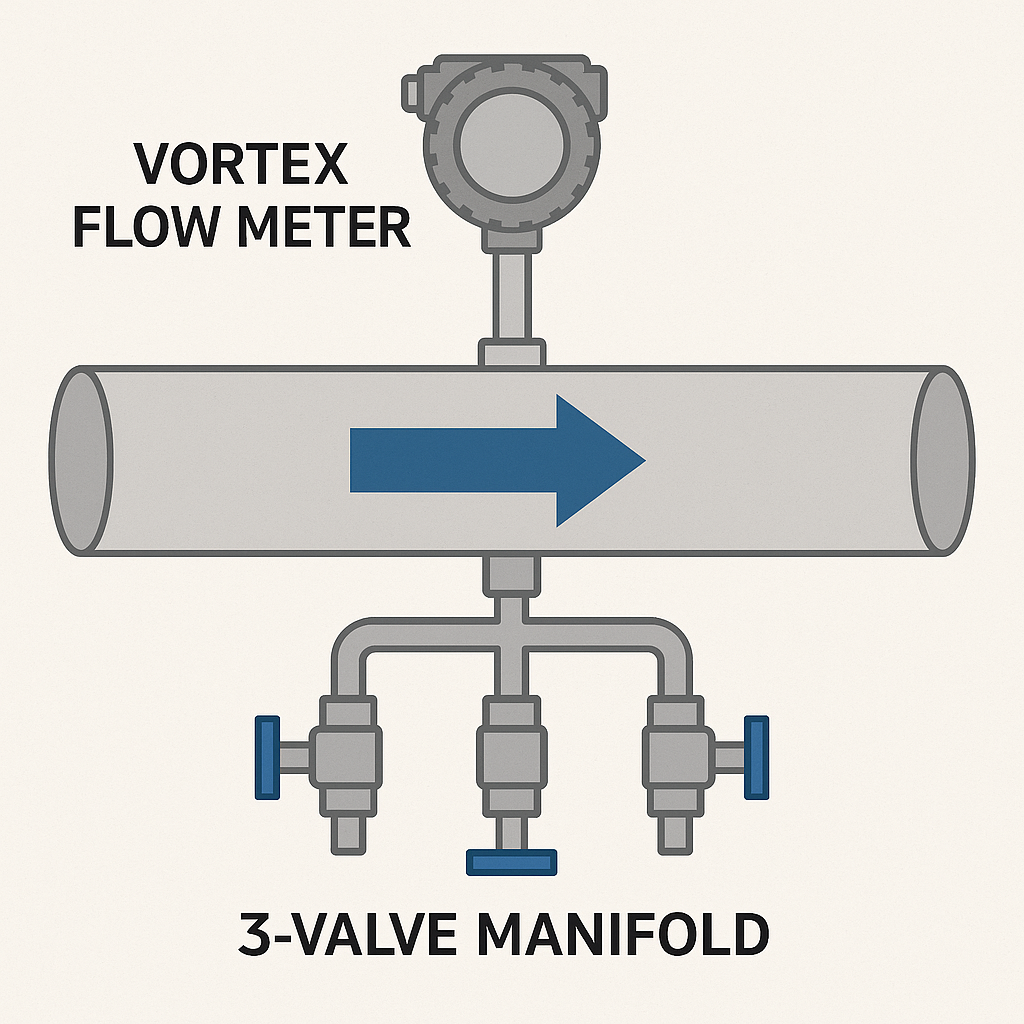

✅ Bonus Tip: Use a Bypass Line for Maintenance

For steam applications, consider installing a 3-valve bypass manifold to allow meter removal or inspection without process interruption.

📌 Conclusion

Even the best vortex flow meters can deliver poor results if installation and operating conditions are neglected. By avoiding these five common mistakes, you can ensure reliable, long-term steam flow measurement with minimal maintenance and downtime.