1. Definition and Background

HART (Highway Addressable Remote Transducer) protocol was developed by Rosemount in the mid-1980s and became an open standard in 1986. It represents a crucial transition from analog to digital communication in industrial automation. By superimposing digital signals over the conventional 4–20 mA analog signal, HART enables remote communication and configuration of field devices.

2. Technical Principle: Hybrid Communication

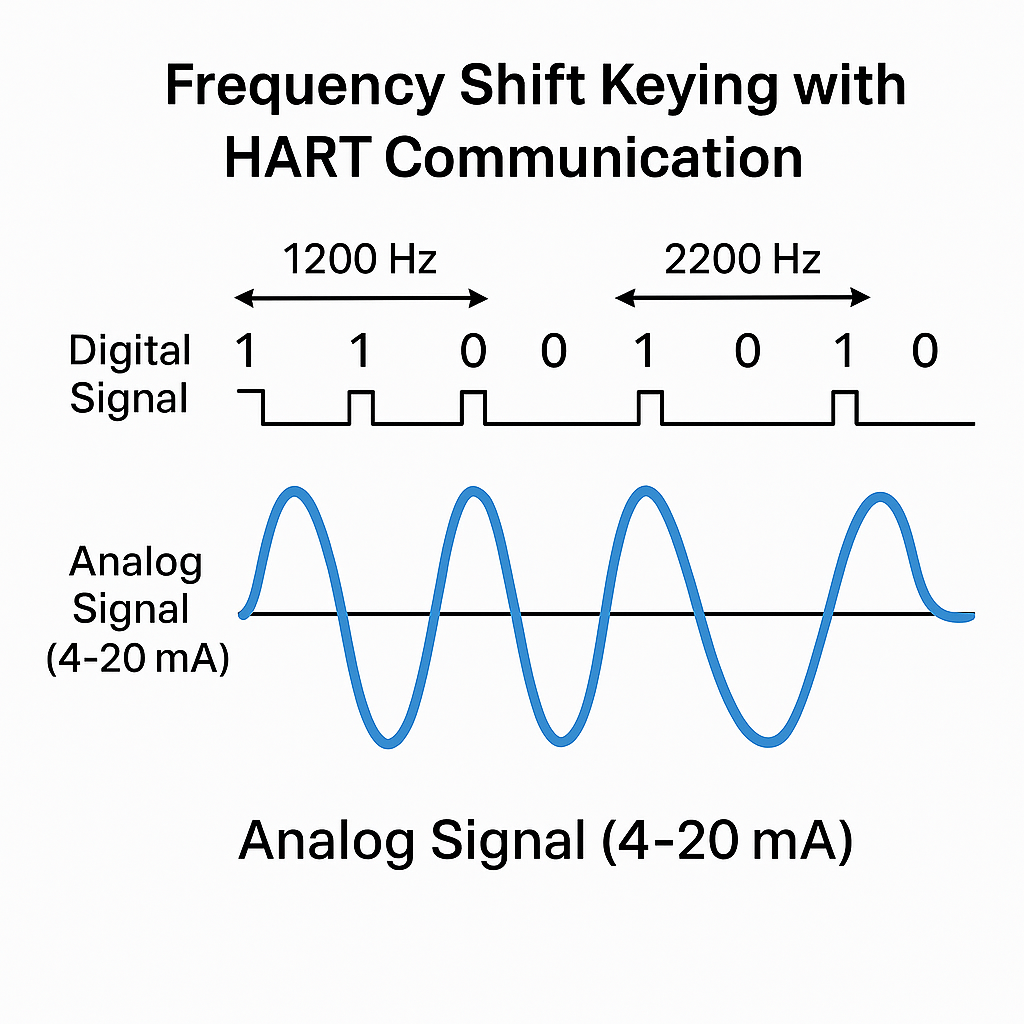

Communication Method:

HART uses Bell 202 Frequency Shift Keying (FSK).

Two sine wave frequencies (1200 Hz for logic “1” and 2200 Hz for logic “0”) are modulated onto the 4–20 mA analog current loop.

Compatibility:

The digital overlay does not interfere with the analog signal.

Ensures seamless integration with legacy systems while enabling smart capabilities.

Figure 1: HART FSK Signal Overlay Diagram

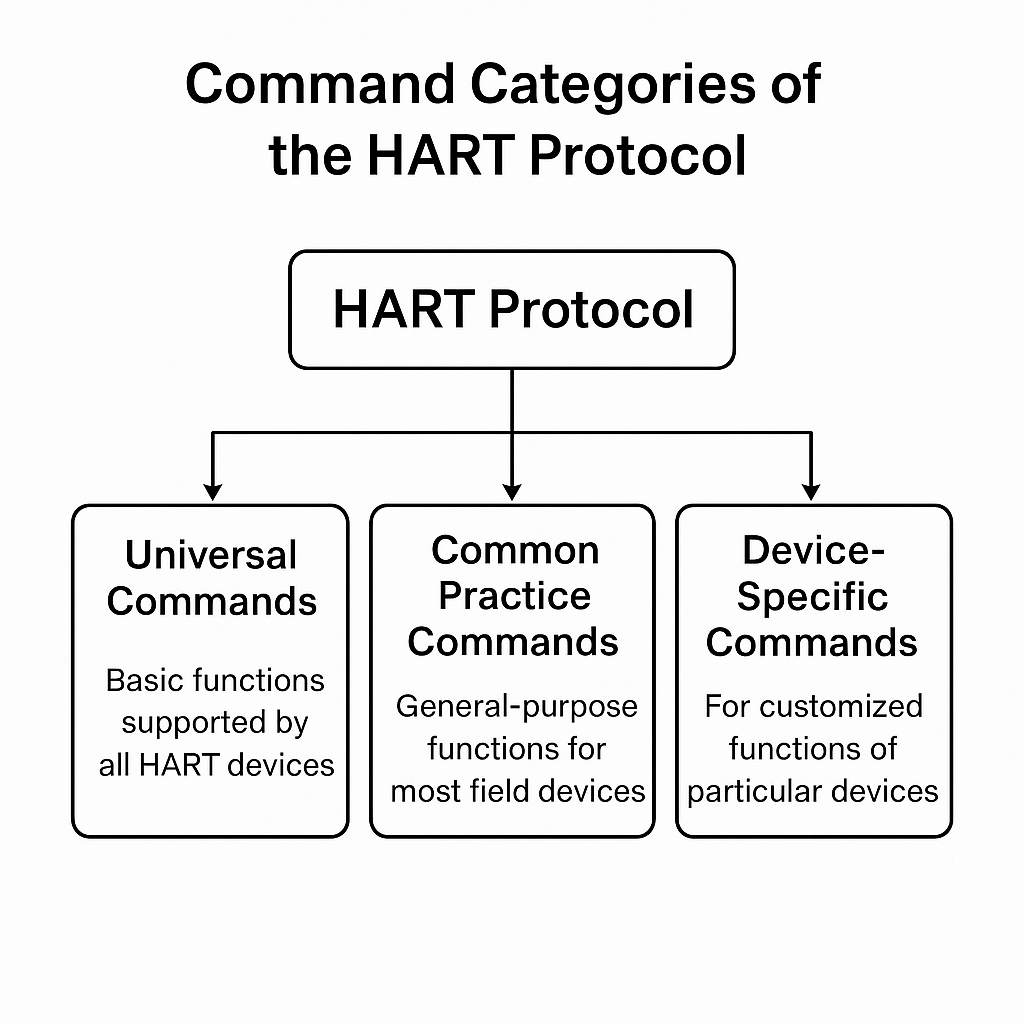

3. Command Structure: Three Functional Layers

Universal Commands: Basic functions supported by all HART devices (e.g., device identification, range setup).

Common Practice Commands: Features used by most devices (e.g., calibration, diagnostics).

Device-Specific Commands: Custom functions developed by individual manufacturers.

Figure 2: HART Command Layer Pyramid

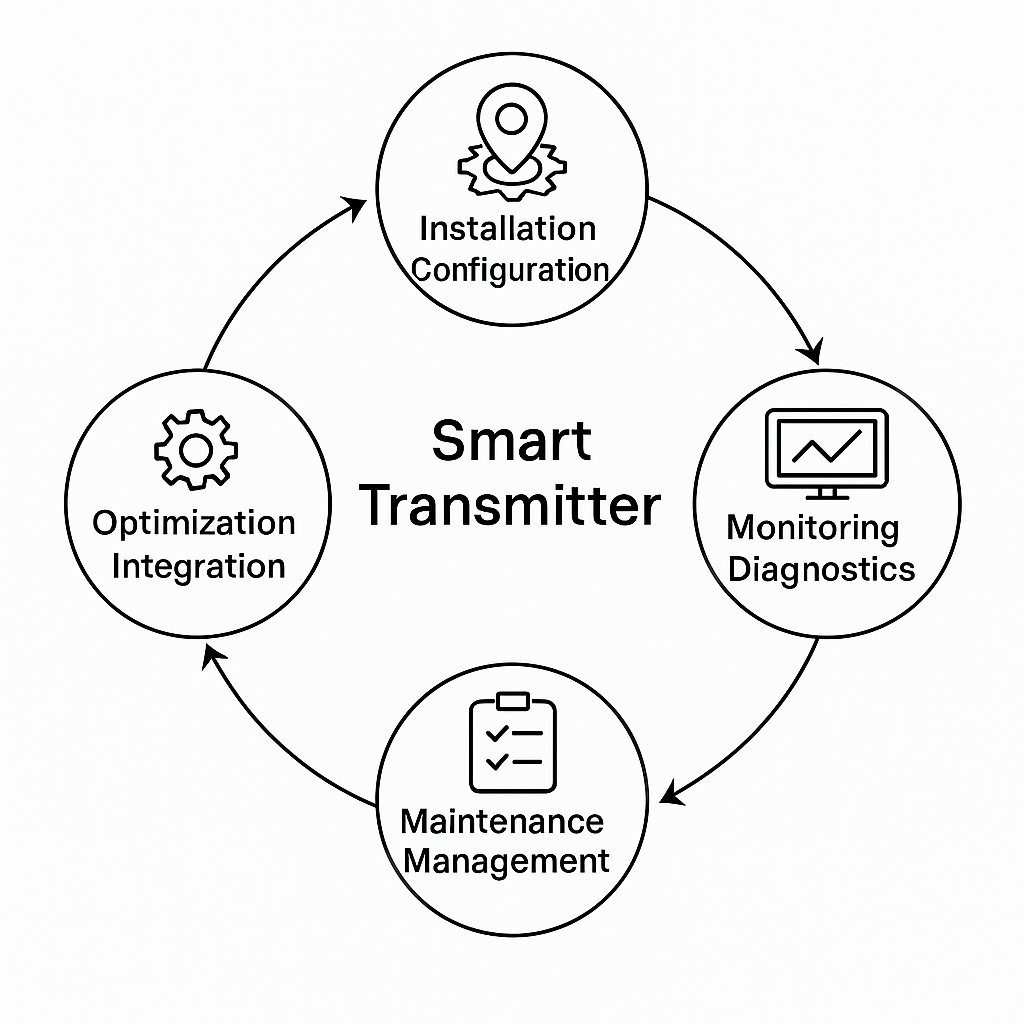

4. Application Advantages of HART-Enabled Instruments

Example: Pressure Transmitter

Efficient Commissioning:

Remotely access device tag, range, model, and location.

Simulate analog outputs for control loop testing.

Predictive Maintenance & Safety:

Detect deviations between analog and digital signals to identify faults early.

Provide real-time device status to safety interlock systems.

Smart Asset Management:

Create electronic instrument records (model, calibration logs).

Remotely fetch diagnostic codes to reduce field troubleshooting.

Cost Reduction:

One device can measure up to 4 variables.

Multidrop mode reduces wiring cost by allowing up to 15 (or 63 with Rev 7) devices on one loop.

Figure 3: Smart Transmitter Lifecycle Advantages

5. Key Features of the HART Protocol

Analog Compatibility: Reuses existing 4–20 mA infrastructure.

Enhanced Functionality: Digital capabilities such as remote configuration and diagnostics.

Flexible Communication Modes:

Point-to-Point Mode: One device per loop with superimposed digital signal.

Multidrop Mode: Fixed current at 4 mA with up to 15/63 devices.

Intrinsically Safe Design: Compliant with explosion-proof standards and bus-powered systems.

Reliable Data Transmission:

Half-duplex master/slave model.

Built-in checksum and error detection.

Interoperability:

Devices described using a standardized Device Description Language (DDL).

Supports multi-vendor systems.

6. Conclusion

The HART protocol, with its hybrid analog-digital approach, remains a cornerstone of smart field communication. It balances compatibility with existing infrastructure and the need for intelligent diagnostics and control. HART-enabled instruments are especially beneficial in process industries like oil & gas, chemical, and power, where safety, reliability, and maintainability are critical.