Steam flow measurement is critical in industries like power generation, chemical processing, and food manufacturing. Two common technologies used for this purpose are vortex flow meters and ultrasonic flow meters. But which one is more suitable for your application? This article compares both technologies in terms of working principles, installation requirements, performance under steam conditions, and cost-effectiveness.

⚙️ 1. Operating Principle

🔸 Vortex Flow Meter:

Uses a bluff body to generate vortices from the flowing steam. The frequency of vortex shedding is proportional to the flow rate and is detected by internal sensors.

Type: Volumetric flow meter

Ideal for: Saturated or superheated steam

Output: Frequency / 4–20mA / pulse / RS485

🔹 Ultrasonic Flow Meter:

Measures the transit time difference between ultrasonic pulses sent upstream and downstream through the steam flow.

Type: Time-of-flight or Doppler

Ideal for: Clean, dry steam or large pipes

Output: 4–20mA / Modbus / HART

🧪 2. Accuracy & Stability

| Feature | Vortex Flow Meter | Ultrasonic Flow Meter |

|---|---|---|

| Typical Accuracy | ±0.75% to ±1.0% | ±0.5% to ±1.0% |

| Low Flow Sensitivity | Moderate (may under-read) | High (better low-end accuracy) |

| Sensitivity to Wet Steam | High (may cause noise) | High (can lose signal) |

| Pressure/Temperature Impact | Minimal | Sensitive to changes |

🔧 3. Installation Considerations

| Aspect | Vortex Meter | Ultrasonic Meter |

|---|---|---|

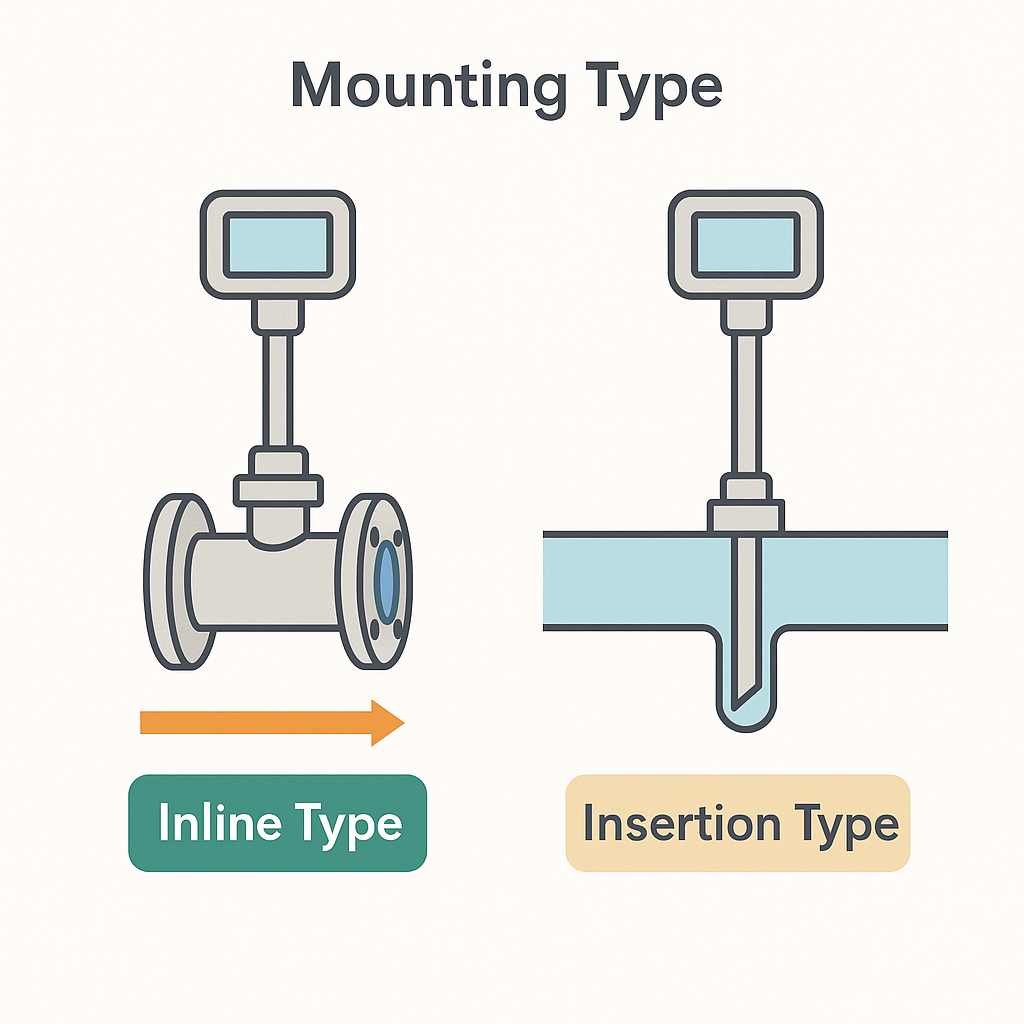

| Pipe modifications | Required (inline installation) | Not required (clamp-on option) |

| Straight-run piping | Essential (10–30×DN) | Less critical (depends on setup) |

| Maintenance | Simple, fewer electronics | Needs dry conditions and good coupling |

| Steam quality required | Medium | High (dry, non-condensing) |

⚠️ Note: Clamp-on ultrasonic meters often struggle with steam due to poor acoustic coupling unless special waveguides are used.

💰 4. Cost Comparison

| Cost Element | Vortex Flow Meter | Ultrasonic Flow Meter |

|---|---|---|

| Meter Price | $$ | $$$–$$$$ |

| Installation Cost | Medium | Low (for clamp-on) |

| Maintenance Cost | Low | Medium |

| Overall ROI | High | High (for large lines) |

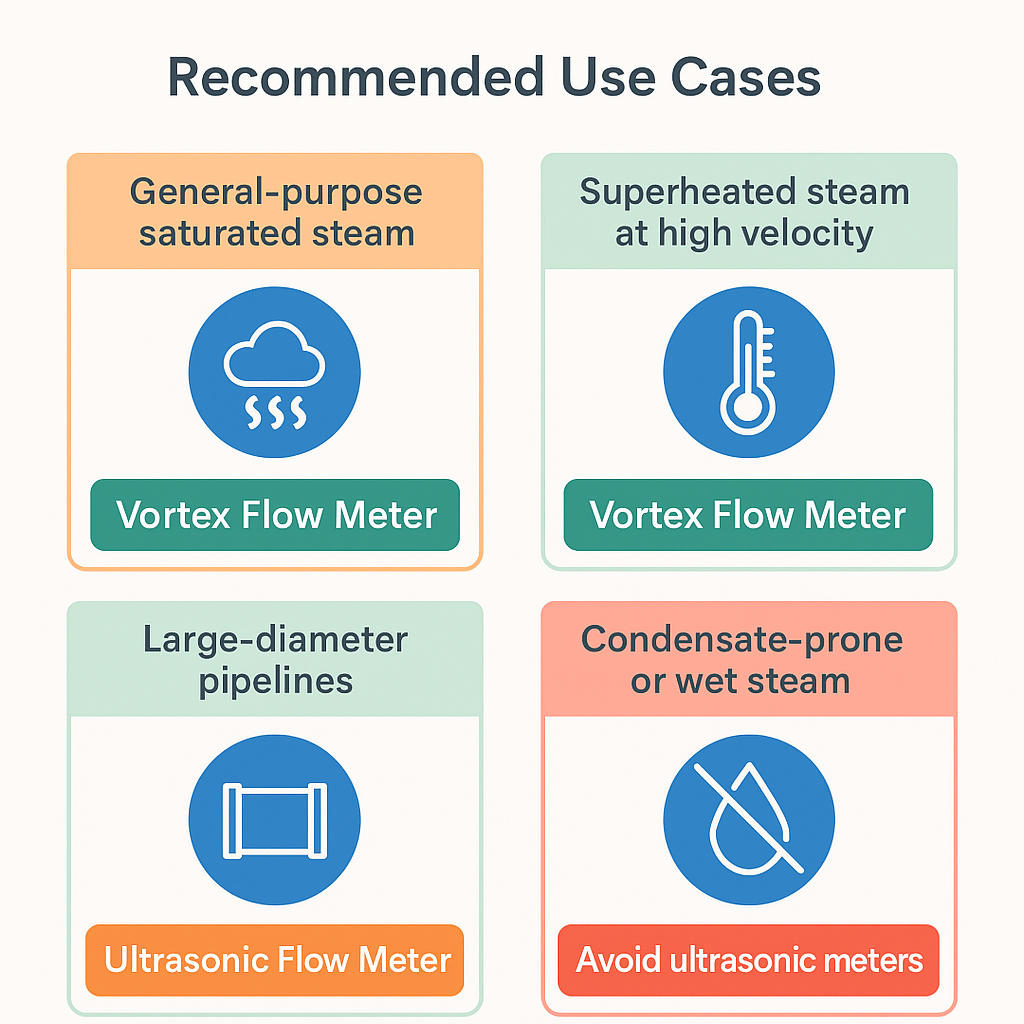

🏭 5. Recommended Use Cases

| Application Scenario | Preferred Meter Type |

|---|---|

| General-purpose saturated steam | ✅ Vortex Flow Meter |

| Superheated steam at high velocity | ✅ Vortex Flow Meter |

| Large-diameter pipelines (> DN300) | ✅ Ultrasonic Flow Meter |

| Sites requiring non-invasive setup | ✅ Ultrasonic (Clamp-on) |

| Condensate-prone or wet steam | ❌ Avoid ultrasonic meters |

📌 Conclusion

Both vortex and ultrasonic flow meters have their place in steam flow measurement. For most industrial steam lines, especially those with medium pipe sizes (DN25–DN300) and stable pressure/temperature, vortex flow meters offer reliable performance at a cost-effective price.

However, for large diameter pipelines or where non-intrusive installation is needed, ultrasonic clamp-on meters provide a good alternative—provided the steam is dry and clean.