1. Major Instrumentation Hazards That Can Lead to Safety Violations

According to national standards and petrochemical safety protocols, the following are frequently cited as major safety hazards:

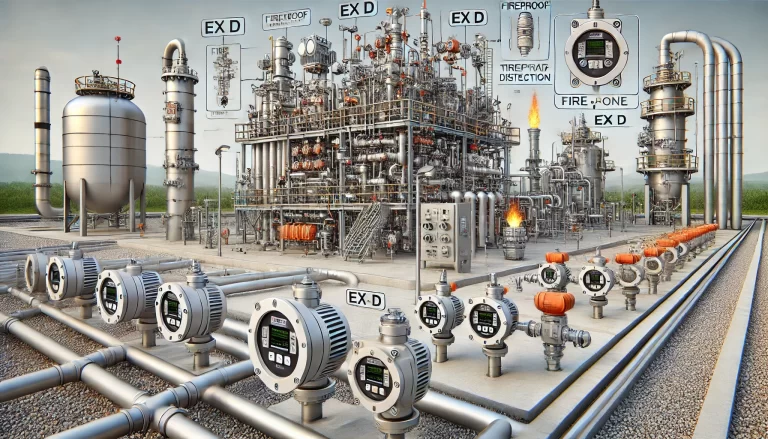

Lack of gas detectors (flammable/toxic) at key emission sources.

Incorrect selection of gas detectors—wrong gas type or specification.

Gas detectors installed but not functioning: power failure, alarm suppression, severe drift, etc.

Use of non-compliant or uncertified explosion-proof devices in hazardous areas.

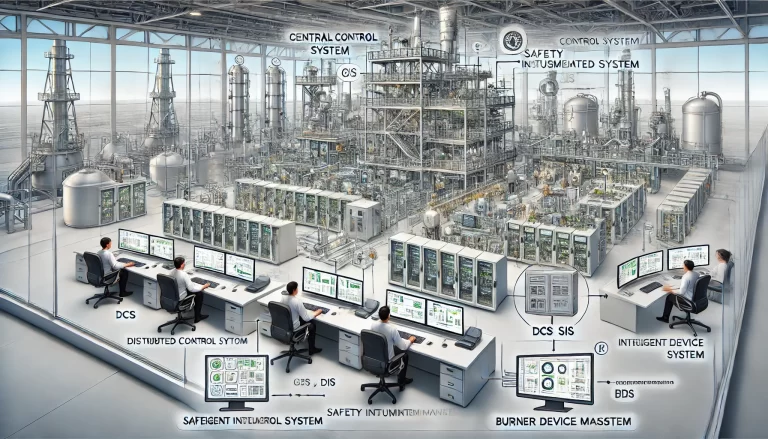

Absence of automated control or emergency shutdown systems in critical process units.

Lack of emergency shut-off function in Class I/II hazardous chemical tank areas; absence of SIS for toxic or liquefied gases.

Control rooms or cabinet rooms located in explosion-prone zones or violating fire separation regulations.

No dual power supply or UPS backup for automation systems.

2. Hazard Identification and Correction – Explosion-Proof Compliance

2.1 Incomplete Explosion-Proof Certification

Requirement: Equipment must include an explosion-proof label with a certificate number from an authorized body (GB 50093-2013 §10.1.2).

Issue: Nameplate lacks the certification number.

Corrective Action: Replace or relabel with certified device.

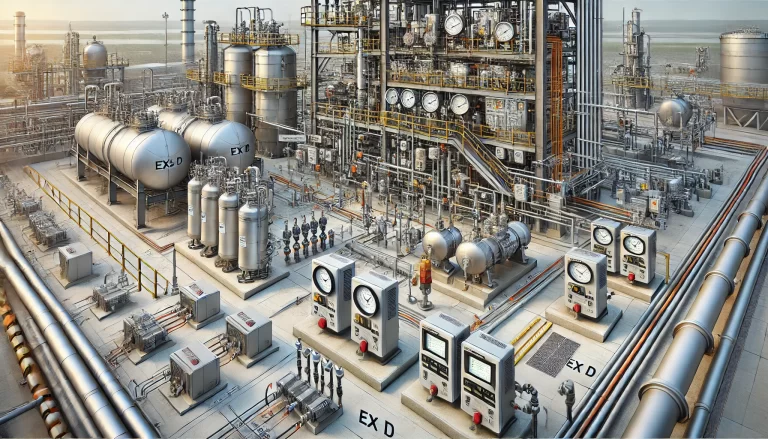

2.2 Improper Cable Gland Sealing

Standard: Explosion-proof cable entries must use appropriate glands or sealing materials (GB 50093-2013 §10.1.3).

Common Faults:

One sealing hole used for two cables.

Unsealed spare openings.

Loose sealing components.

Corrective Action: Ensure each cable has an individual gland; plug unused holes with certified fittings.

2.3 Loose Bolting at Explosion-Proof Interfaces

Standard: Fasteners and anti-loosening components (spring washers, etc.) must be present and secure (GB 50257-2014 §4.2.1.4).

2.4 Improper Flexible Conduit Termination

Requirement: Flexible conduit between field instruments and enclosures must include drip loops and waterproof seals (GB 50093-2013 §7.4.8).

3. Hazard Identification and Correction – Installation Non-Conformities

3.1 Upward Cable Entry on Junction Boxes

Issue: Entry ports facing upward increase water ingress risk.

Standard: Entry points must not face upward (GB 50093-2013 §6.1.9).

3.2 Missing Drainage Tee on Conduits

Standard: Protective conduits must be installed sloped and include a drain tee (SH/T 3019-2016 §7.3.6).

3.3 No Isolation Seal at Entry Points in Hazardous Zones

Standard: Isolation sealing must be provided within 450 mm of all ignition sources (GB 50058-2014 §5.4.3.5).

3.4 Improper Cable Tray Outlet Openings

Standard: Mechanical drilling required at side of tray, ideally at 2/3 height; holes must be smooth (SH/3569-2020 §7.1.15).

3.5 Unprotected or Tightly Bent Capillaries

Standard: Minimum bending radius ≥ 50mm; must be shielded from rapid temperature changes (GB 50093-2013 §6.1.12).

3.6 Incorrect Air Source Entry

Issue: No filter-regulator or incorrect orientation.

Standard: Air inlet must have filter and pressure reducer, installed vertically (SH/T 3551-2013 §12.1.5).

3.7 Missing Manual Shut-off Valve with Seal

Standard: Pneumatic control lines must include a sealable manual shutoff valve (SH/T 3005-2016 §10.3.6.8).