Introduction

When integrating a load cell into your weighing system, one of the most overlooked—but critical—decisions is choosing the correct wiring configuration.

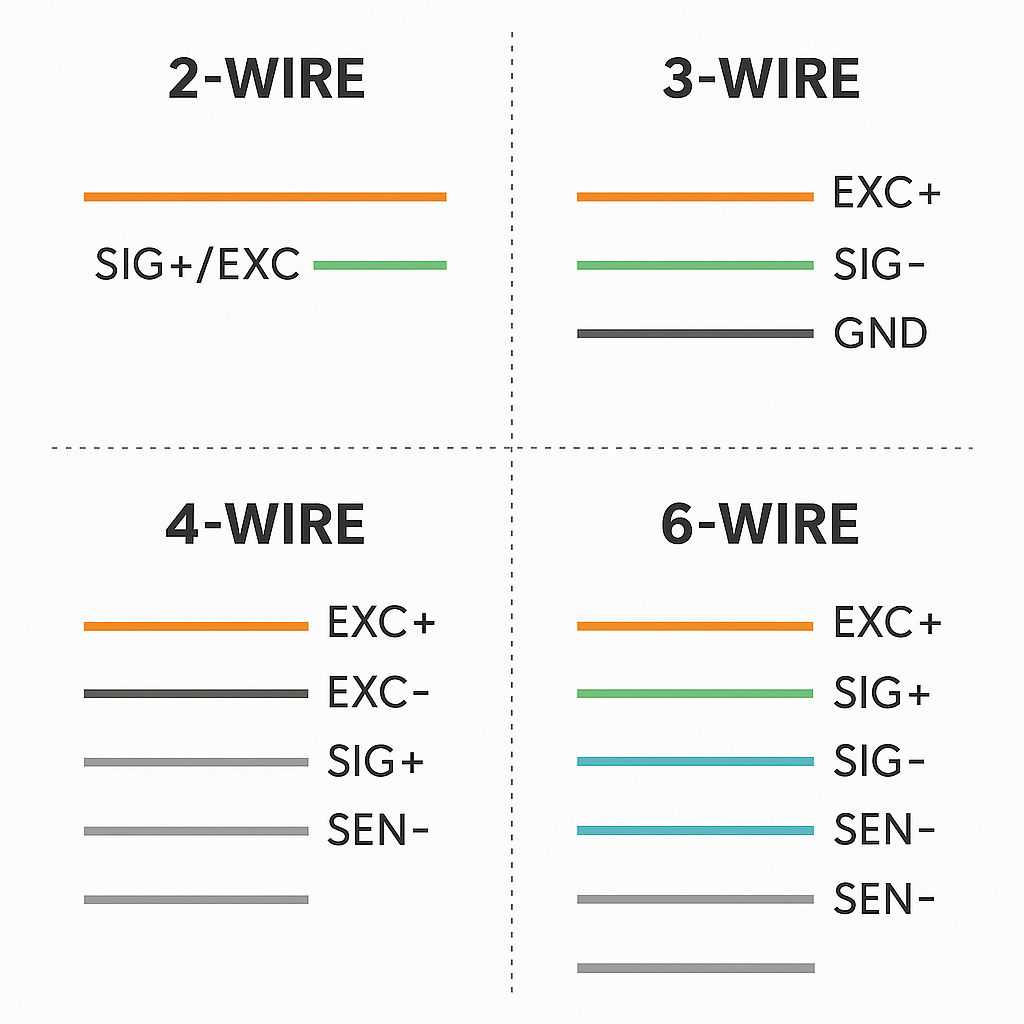

You may encounter 2-wire, 3-wire, or 4-wire load cells in specifications or datasheets.

So… what’s the difference, and why does it matter?

This article explains each wiring type, its pros and cons, and which one is best for your application.

1. Basic Concepts: What Do Load Cell Wires Do?

Typical strain gauge load cells include these types of wires:

Excitation+ / Excitation- (EX+ / EX−): Power supply to the bridge circuit

Signal+ / Signal- (SIG+ / SIG−): Voltage output proportional to load

Sense+ / Sense- (SEN+ / SEN−) (for 6-wire): Feedback to compensate voltage drops

Ground / Shield (optional): EMI shielding

The wiring configuration affects accuracy, stability, and ease of installation.

2. 2-Wire Load Cells

⚙️ Signal and excitation share the same wires

🟢 Pros:

Simplest wiring

Cost-effective

Often used in 4–20 mA current loop output sensors

🔴 Cons:

No separation of signal and power → susceptible to noise

Limited to current-output systems (not standard strain gauge types)

Not used for precision applications

🧩 Use Case:

Rugged industrial sensors where simplicity is more important than high accuracy.

3. 3-Wire Load Cells

⚙️ One wire for excitation, one for signal, and one for ground

🟢 Pros:

Basic separation between power and signal

Suitable for low-cost weighing systems

Easier wiring than 4-wire

🔴 Cons:

No sense lines → voltage drops across long cables cause errors

Ground loop issues in some installations

Affected by temperature and wire resistance

🧩 Use Case:

Short cable runs or small bench-scale systems where ultra-high precision is not required.

4. 4-Wire Load Cells

⚙️ Separate wires for excitation and signal, but no feedback/sense wires

🟢 Pros:

Industry standard for most load cells

Good balance of simplicity and accuracy

Compatible with most commercial weighing indicators

Better immunity to noise than 2- or 3-wire setups

🔴 Cons:

Voltage drop across long cables can affect output

No built-in compensation for cable resistance like 6-wire models

🧩 Use Case:

Platform scales, hopper/tank weighing, general-purpose industrial weighing.

Bonus: 6-Wire Load Cells (for completeness)

⚙️ Adds Sense+ and Sense- wires to measure actual voltage at the load cell

🟢 Pros:

Compensates for voltage drop across long cables

Temperature and drift resistant

Best for high-precision, long-cable installations

🔴 Cons:

Requires compatible indicators or transmitters

Slightly more complex wiring

🧩 Use Case:

Truck scales, silo systems, weighbridges, batching systems with >10m cable.

5. Comparison Table

| Feature | 2-Wire | 3-Wire | 4-Wire | 6-Wire |

|---|---|---|---|---|

| Number of conductors | 2 | 3 | 4 | 6 |

| Signal/Excitation separation | ❌ | ✅ (partial) | ✅ | ✅ |

| Compensates cable losses | ❌ | ❌ | ❌ | ✅ |

| Accuracy level | Low | Medium | High | Very High |

| Noise immunity | Medium | Medium | High | Very High |

| Recommended for | Industrial loop | Small scales | Most scales | Precision/remote |

Conclusion

The number of wires in a load cell directly affects its accuracy, noise resistance, and compatibility.

✅ 2-wire: Use only for current loop transmitters

✅ 3-wire: Acceptable for short-range, low-precision tasks

✅ 4-wire: Best general-purpose solution for 90% of applications

✅ 6-wire: Ideal for precision and long-distance installations

When in doubt, go with 4-wire—but if you need top accuracy over long distances, 6-wire is worth it.