Cable tray installation must comply with specific technical standards to ensure electrical safety, system reliability, and long-term maintainability. This document outlines the key requirements for cable tray layout, installation, and fireproofing in industrial and commercial environments.

1. Route Planning and Layout Principles

Coordinate with Building Structure: Cable tray routing should align with architectural design, avoiding unnecessary crossings, detours, or overlaps with other pipelines.

Shortest and Straightest Path: To reduce cable loss and simplify maintenance, cable routes should be as short and straight as possible.

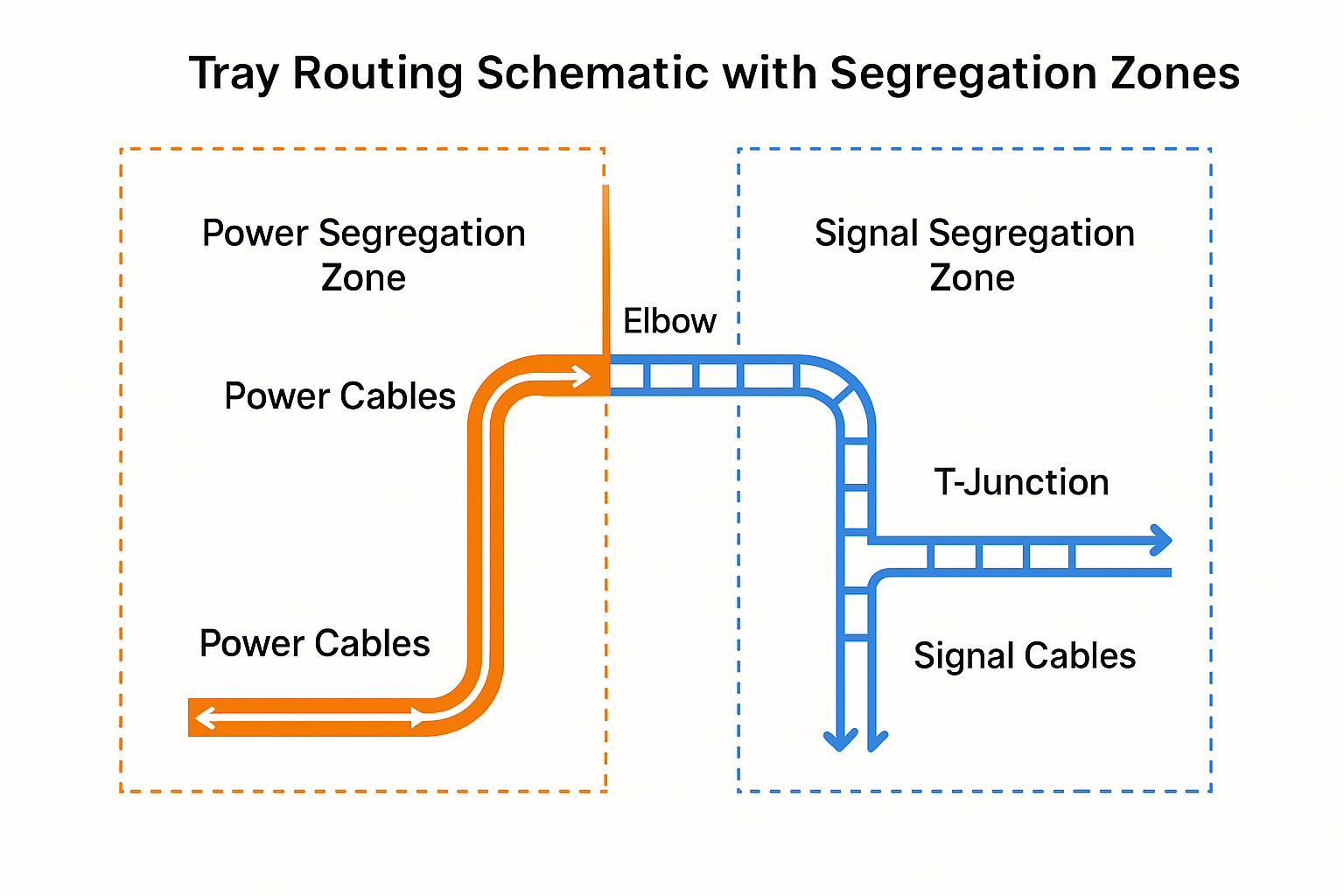

Segregation of Power and Signal Cables: Power (high-voltage) and signal (low-voltage) cables should be routed separately, using dedicated trays to minimize electromagnetic interference.

2. Tray Type and Material Selection

Based on Environment:

Indoor: Painted steel or galvanized trays.

Outdoor: Hot-dip galvanized or stainless steel trays.

Corrosive/High Humidity: Aluminum alloy or fiberglass-reinforced plastic trays.

Based on Load Capacity:

Select the tray width and thickness according to the number and weight of cables.

Ensure mechanical strength is sufficient to prevent deformation or failure under full load.

3. Installation Technical Requirements

Alignment:

Horizontal deviation: ≤2mm per meter.

Vertical deviation: ≤3mm per meter.

Must be level, plumb, and securely mounted on supports.

Joint Connections:

Use dedicated splice plates and bolts.

Ensure firm electrical continuity through grounding jumpers at each connection point.

Sharp edges or foreign debris inside the tray must be removed to prevent cable damage.

4. Optical Cable Laying Guidelines

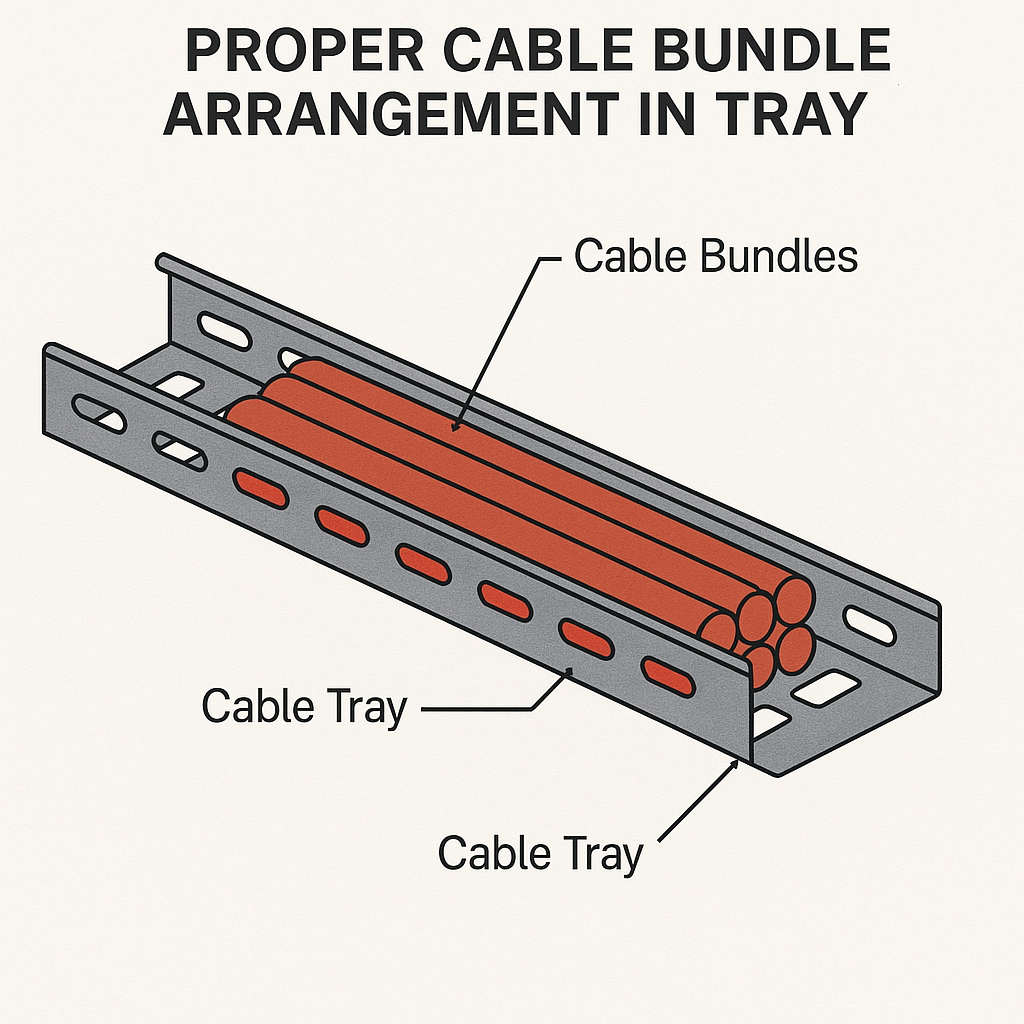

Arrangement: Cables must be laid in a neat, parallel fashion, avoiding twists and crossovers.

Fixing: Use cable ties or clips at regular intervals to secure cables in place and prevent movement.

Tension Control:

Single-mode fiber: Maximum pulling force ≤1500 N.

Multi-mode fiber: Maximum pulling force ≤1000 N.

5. Directional Changes and Branching

Use standard accessories such as:

Horizontal/vertical elbows,

T-junctions,

Cross-junctions.

These components ensure a clean, structured appearance and mechanical stability.

6. Fireproofing Measures for Cable Trays

6.1 Material Requirements

Fire-resistant trays must be made from non-combustible or flame-retardant materials such as:

Galvanized steel,

Stainless steel,

Fire-resistant coated trays,

Flame-retardant plastic composites.

Surfaces should be coated with fire-retardant paint to slow flame spread and increase heat resistance.

6.2 Fire Barrier Integration

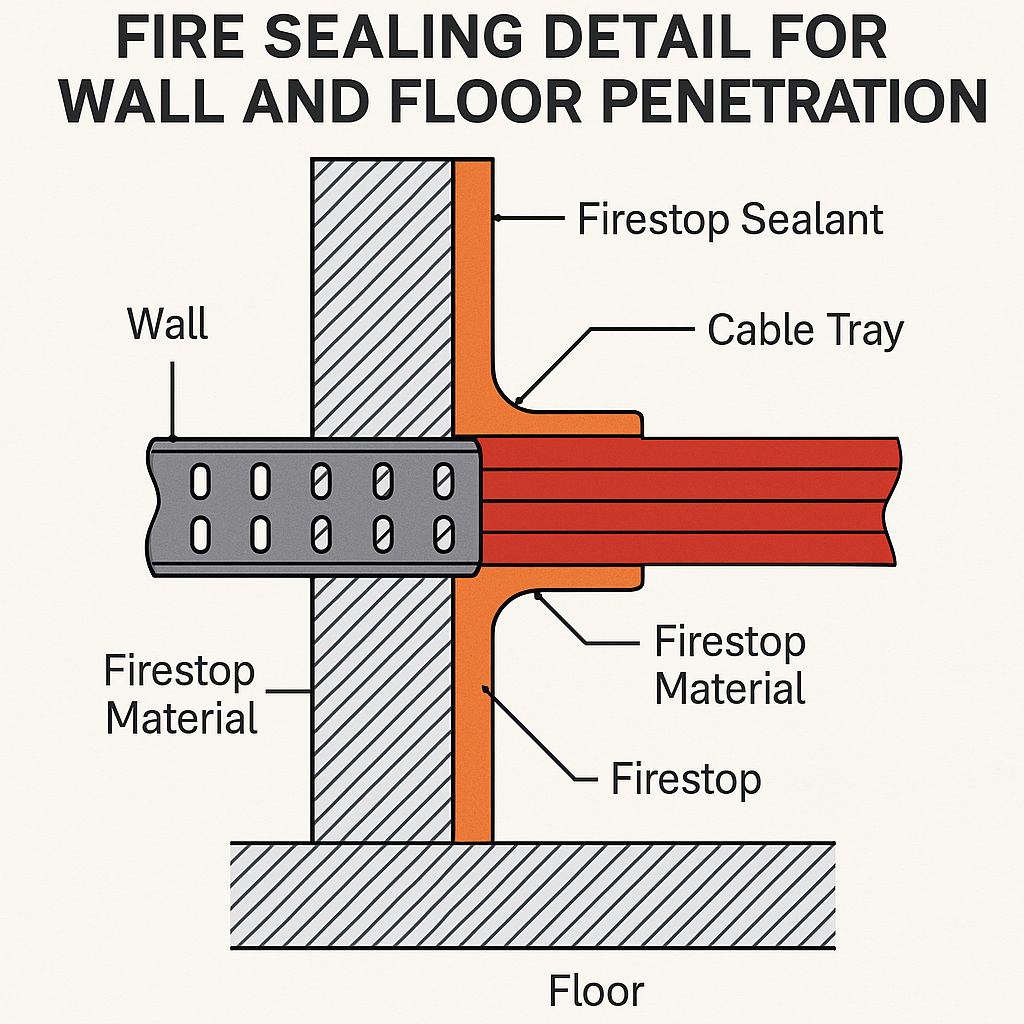

Install fire barriers within the tray to isolate different fire zones.

When cable trays pass through walls or floors, seal openings using fire-rated penetration sealing materials.

6.3 Fireproof Tray Application Notes

Only use fireproof trays for flame containment or isolation, not for unrelated functions.

Do not modify or damage the tray coating or structure during use.

If any abnormality is detected (corrosion, deformation), suspend use and inspect immediately.

Perform routine cleaning and fire resistance checks to ensure long-term effectiveness.

7. Heat Dissipation Considerations

For high-power cables or heat-sensitive systems:

Use perforated trays or wire mesh trays to improve airflow.

Maintain adequate clearance between cables to avoid heat accumulation.

8. Inspection and Maintenance

Post-installation Check:

Ensure tray connections are firm, straight, and properly aligned.

Confirm grounding continuity and absence of mechanical damage.

Routine Maintenance:

Periodically inspect outdoor trays for rust, moisture accumulation, or UV damage.

Fireproof trays require scheduled inspection for coating integrity and sealing effectiveness.