The diaphragm of a pressure transmitter plays a crucial role in determining measurement accuracy, long-term stability, and the overall reliability of the device. Choosing the correct diaphragm material and structure is essential to ensure optimal performance and durability, especially in demanding industrial environments.

1. Understand the Properties of the Measured Medium

The first step in selecting a suitable diaphragm is to understand the physical and chemical characteristics of the process medium, including:

Chemical composition (e.g., acids, alkalis, saltwater)

Temperature

Viscosity

Corrosiveness

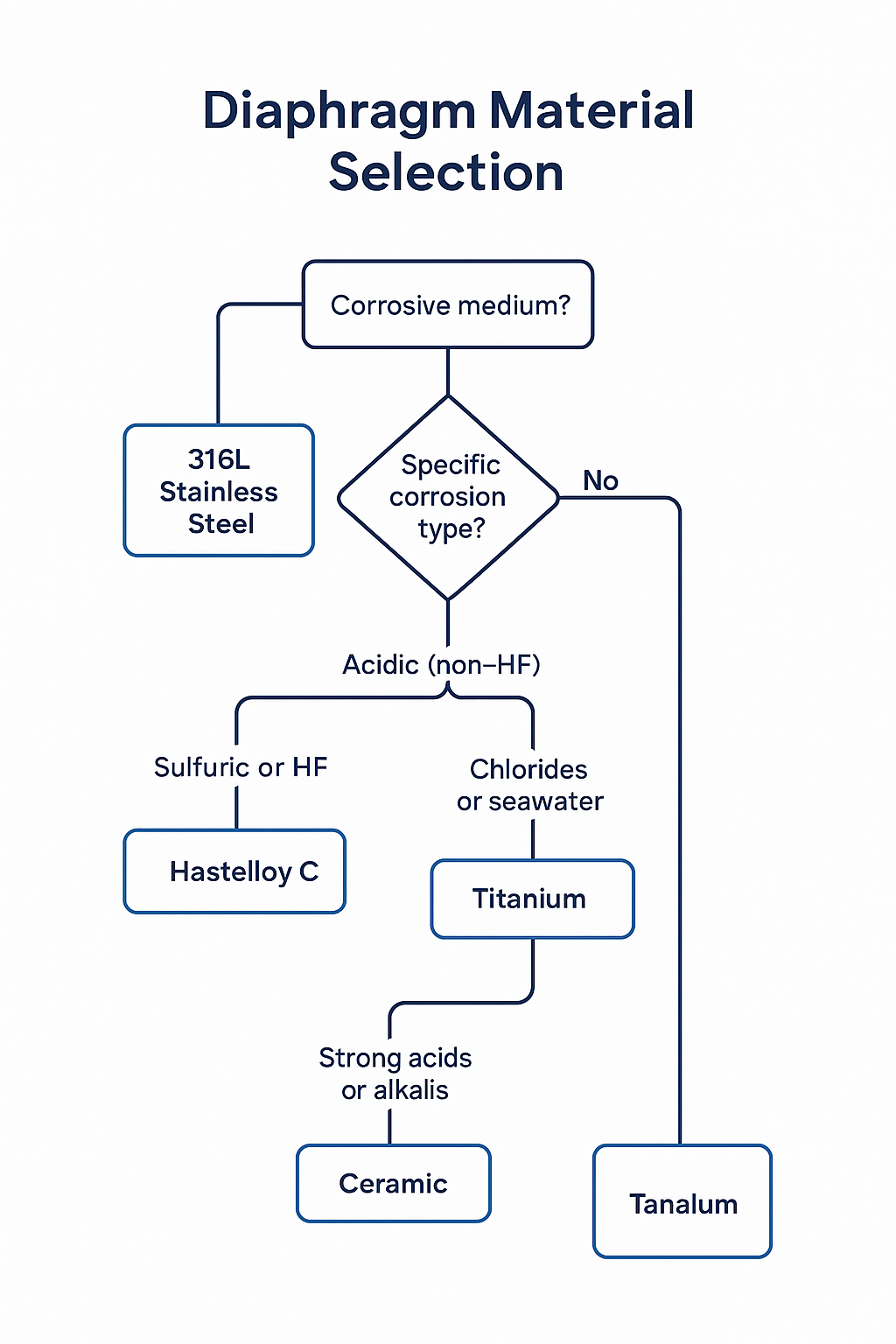

Highly corrosive media require diaphragms made of materials with superior corrosion resistance, such as Hastelloy C, titanium alloys, or tantalum.

2. Diaphragm Material Options and Their Applications

| Material | Corrosion Resistance | Typical Applications | Limitations |

|---|---|---|---|

| 316L Stainless Steel | Good (general-purpose) | Water, air, mild chemicals | Not suitable for highly corrosive media |

| Hastelloy C | Excellent in most acids (except HF) | Phosphoric acid, acidic gas, chemical processes | Avoid high-concentration sulfuric/nitric acid |

| Titanium Alloy | Excellent for chlorides, seawater | Seawater, brine, chlorine environments | Not for hydrofluoric acid or strong alkalis |

| Tantalum | Superior in highly corrosive media | Strong acids, aggressive chemicals | High cost |

| Ceramic (Al₂O₃, ZrO₂) | Very good in aggressive chemicals | Acidic or oxidizing environments | Lower mechanical flexibility & long-term drift |

3. Consider Environmental Factors

Hydrogen Environments:

For applications involving high concentrations of hydrogen (70–100%), use gold-plated diaphragms to avoid hydrogen embrittlement.High Temperature Conditions:

For processes between 200°C and 400°C, select high-temperature-rated diaphragms. These prevent silicone oil vaporization, which can lead to significant measurement errors.

4. Accuracy Requirements

For applications requiring high precision:

Select transmitters with higher accuracy classes (e.g., ±0.1%).

Ensure diaphragm thickness and profile support accurate and stable signal transmission.

5. Installation and Maintenance Considerations

Ease of installation and maintenance is a practical factor:

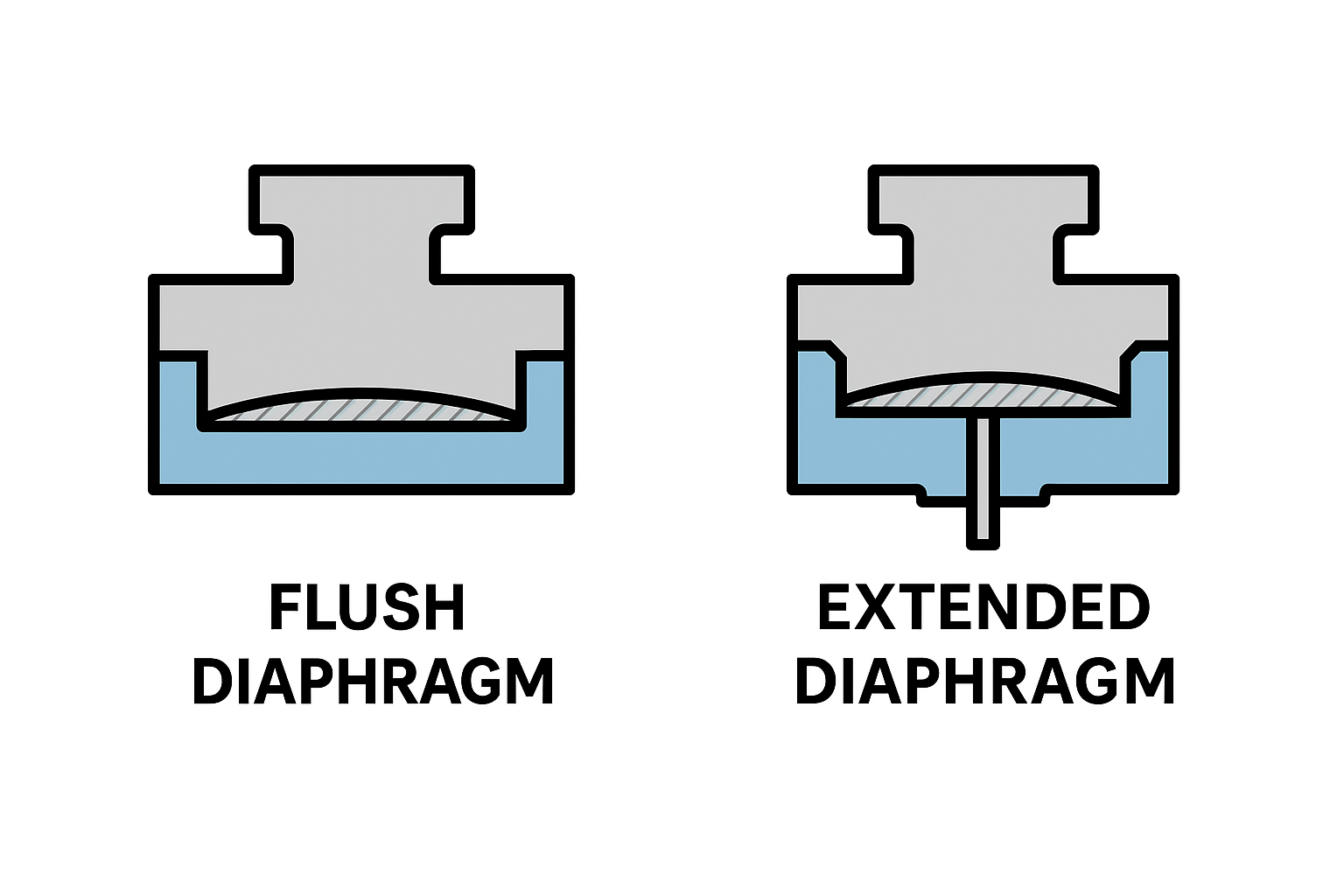

Flush-type diaphragms (flat diaphragms) are easier to clean and are preferred in viscous or crystallizing media.

Consider removable diaphragm seals for maintenance-heavy environments.

6. Special Applications in Harsh Industries

In highly demanding environments such as petrochemical, power plants, or pharmaceutical processes:

Select custom diaphragm configurations or multi-layer structures.

Ensure compatibility with welded seals, capillary extensions, or remote seal designs for safety and reliability.

Conclusion

Selecting the right diaphragm for a pressure transmitter requires a balanced consideration of the process medium, environmental conditions, measurement requirements, and long-term maintenance strategy. Proper diaphragm selection enhances not only measurement accuracy but also ensures operational safety and system longevity.