In complex fluid control systems, pressure units can often be confusing, with different terms used to describe seemingly similar concepts. One common source of confusion is the distinction between PN16 and 1.6 MPa. While they may appear equivalent at first glance, their definitions, applications, and implications vary significantly. This article aims to clarify the differences and relationships between these two pressure terms from a technical and engineering perspective.

1. What Is PN16? – A Nominal Pressure Indicator

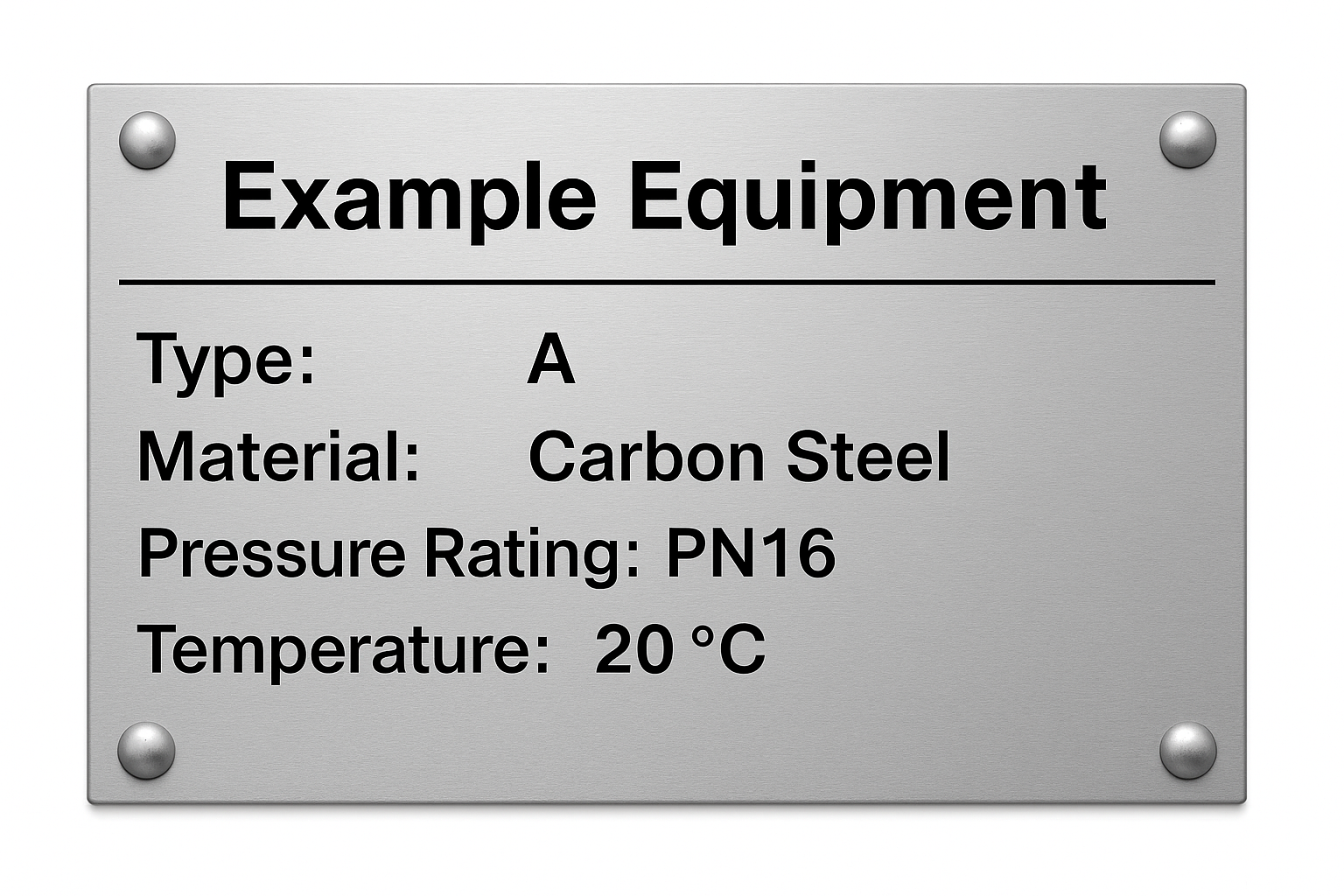

PN16 refers to the Nominal Pressure Rating of industrial components such as valves, pipelines, and flanges. It is a standardized designation that indicates the pressure-bearing capacity of a component under specific conditions.

▶ Meaning of PN16

PN stands for “Pressure Nominal”.

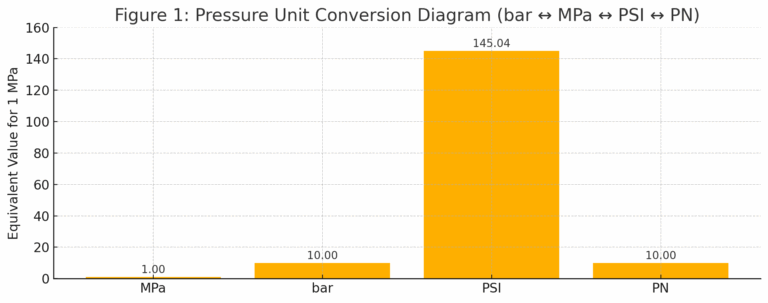

The number 16 denotes 16 bar, which is equivalent to 1.6 MPa (since 1 bar ≈ 0.1 MPa).

PN16 specifies that the component is designed to withstand a maximum operating pressure of 16 bar at a reference temperature of 20°C.

▶ Typical Applications

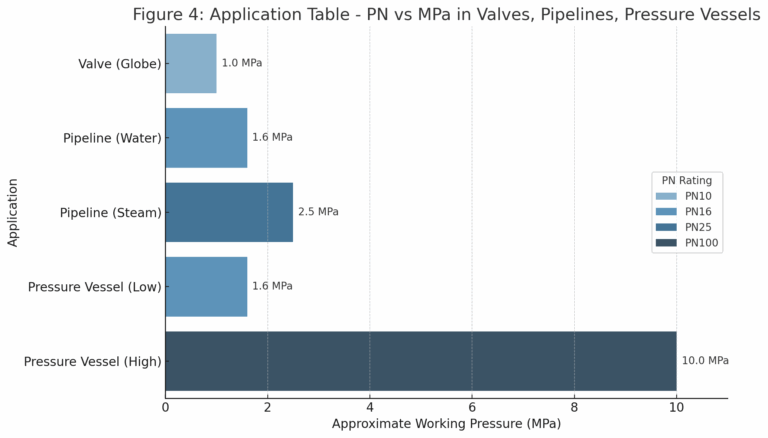

PN16 ratings are commonly found on:

Valves

Pipe fittings

Flanged connections

These ratings help ensure that components are suitable for systems operating up to 1.6 MPa under normal temperature conditions.

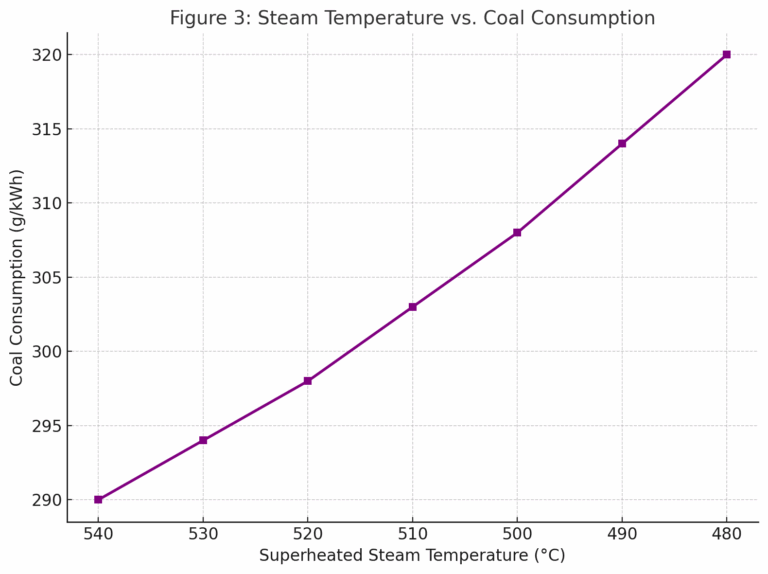

▶ Temperature Derating Consideration

The PN16 rating is valid at 20°C. As the temperature increases, the material strength may decrease, leading to a lower allowable pressure. Therefore, temperature-pressure derating curves must be used when operating at elevated temperatures.

2. What Is 1.6 MPa? – An Actual Pressure Measurement

1.6 MPa uses the SI (International System of Units) to express pressure. It is a direct, absolute pressure value and not a design classification like PN.

▶ Meaning of 1.6 MPa

MPa stands for Megapascal (1 MPa = 1,000,000 Pa).

1.6 MPa directly refers to a measured pressure of 1.6 Megapascals.

▶ Typical Applications

Unlike PN16, 1.6 MPa is:

Used across a wide range of fluid systems, including hydraulic, pneumatic, and process systems.

Often applied to describe real-time system pressure, such as pressure within a pipeline or pressure vessel.

▶ Relation to Temperature

Unlike PN ratings, 1.6 MPa is a static value and does not inherently consider temperature. However, system design must still account for temperature effects on materials and seals.

3. Key Differences and Similarities Between PN16 and 1.6 MPa

| Aspect | PN16 | 1.6 MPa |

|---|---|---|

| Nature of Value | Nominal pressure class (design-based) | Actual working pressure (measured value) |

| Unit Conversion | PN16 = 16 bar = 1.6 MPa | 1.6 MPa = 16 bar = PN16 (numerically equal) |

| Application Scope | Used in component rating (valves, pipes) | Used in system pressure measurement |

| Temperature Dependence | Defined at 20°C with derating required | Not defined by temperature; context dependent |

| Relevance | Reflects mechanical design capacity | Reflects real-time operating conditions |

4. How to Use These Terms Correctly

✅ Identify the Context of Use

For equipment selection, refer to PN ratings to ensure components can handle design pressures, considering fluid properties and temperature.

For system analysis or documentation, use MPa to reflect actual pressure readings.

✅ Avoid Conceptual Confusion

While PN16 and 1.6 MPa are numerically equivalent, they are not interchangeable. PN16 refers to a rating based on engineering standards, while 1.6 MPa is a unit of measurement.

✅ Consider Temperature Derating

Always check material-specific temperature-pressure curves when operating above 20°C to prevent pressure overload and equipment failure.

Conclusion

Although PN16 and 1.6 MPa both reference a pressure level of 1.6 Megapascals, they serve different functions in the fluid control industry. Understanding the design implications of PN16 versus the measured reality of 1.6 MPa helps engineers make accurate and safe decisions when selecting components or analyzing systems. By recognizing the differences and using these terms appropriately, you can avoid common misunderstandings and ensure optimal system performance.