Introduction

As robotic systems become more intelligent and dexterous, they increasingly require feedback in all directions—not just linear force or rotational torque.

This is where 6-axis force/torque (F/T) sensors come into play. These advanced sensors provide real-time data on forces and torques in all three spatial dimensions, enabling precise control, collision detection, and adaptive behavior.

This article explains how 6-axis sensors work, where they are used, and what to consider when selecting one for your system.

1. What Is a 6-Axis Force/Torque Sensor?

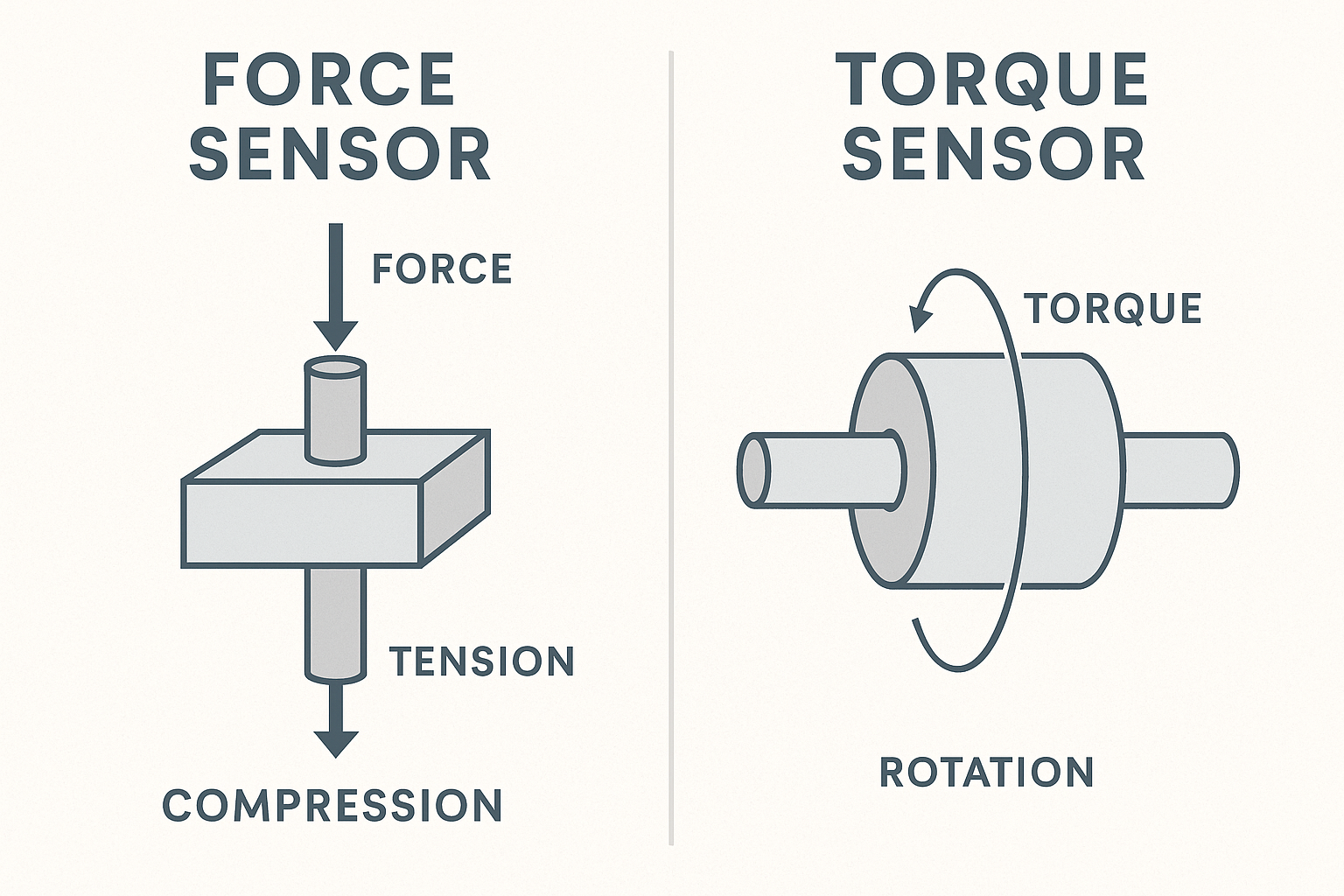

A 6-axis F/T sensor is a device that measures:

Forces: Fx, Fy, Fz (X, Y, and Z directions)

Torques: Mx, My, Mz (rotation around X, Y, Z axes)

📌 That means you get a complete picture of how your robot or machine interacts with its environment.

It’s like giving your robot a sense of “touch and resistance” in every direction.

2. How Does It Work?

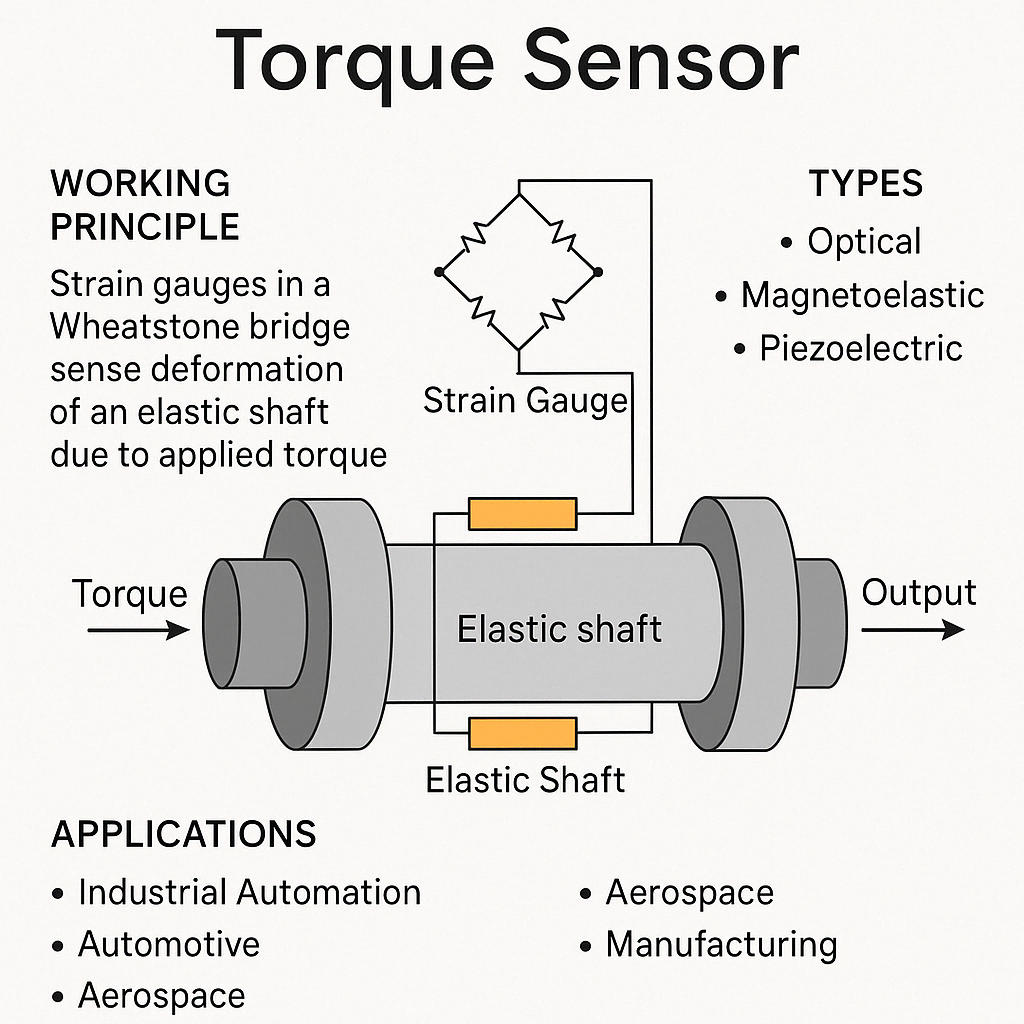

Inside the sensor is a strain gauge or MEMS-based sensing core, mounted on a flexure structure. When forces or torques are applied, the structure deforms slightly, and the internal sensors measure strain in all directions.

The sensor then outputs six independent signals—either analog or digital—that can be fed into a controller, robot arm, or data acquisition system.

3. Benefits of 6-Axis Sensing

✅ Multidirectional Awareness

Capture full 3D force and torque interaction in real time.

✅ Precision Assembly and Compliance Control

Enable force-guided motion, soft contact, or automatic insertion.

✅ Improved Safety in HRC

Detect unintended contact in collaborative robotics.

✅ Increased Flexibility

Adapt to varying load angles, surface positions, and part tolerances.

✅ Unified Sensor Footprint

Eliminates the need for multiple single-axis sensors.

4. Typical Applications

| Application | Use of 6-Axis Sensor |

|---|---|

| Robotic Assembly (e.g. press-fit) | Ensures correct insertion angle + contact force |

| Surface Polishing / Deburring | Maintains constant tool pressure in multiple directions |

| Surgical and Medical Robotics | Detects subtle human–robot interactions |

| Product Testing / R&D Labs | Measures load paths, contact forces, and joint movement |

| Prosthetics & Exoskeletons | Provides feedback for natural movement control |

| Teleoperation / Haptics | Simulates real-world touch via force feedback |

5. Key Selection Criteria

Measuring Range: Ensure each axis has sufficient capacity (e.g., Fx = ±200 N, Mz = ±10 Nm)

Output Type: Choose from analog voltage, USB, RS485, EtherCAT, etc.

Size and Weight: Consider impact on end-effector dynamics

Mounting Interface: Compatible with robotic wrists or platforms

Sampling Rate: Fast enough for dynamic motion control (>1 kHz preferred)

IP Rating: For industrial use, look for IP65+ protection

6. Challenges to Consider

Cost: 6-axis sensors are more expensive than single-axis models

Integration: Requires controller support for 6 DoF data streams

Signal Processing: May need filtering or calibration matrix adjustments

Space Constraints: Compact robots may not accommodate larger sensor bodies

Conclusion

6-axis force/torque sensors offer unmatched insight into how your robotic system physically interacts with the world. Whether you’re building a flexible assembly robot or conducting advanced material tests, these sensors unlock new levels of responsiveness, safety, and performance.

When accuracy and multi-directional feedback matter, a 6-axis sensor is not a luxury—it’s a necessity.