Introduction

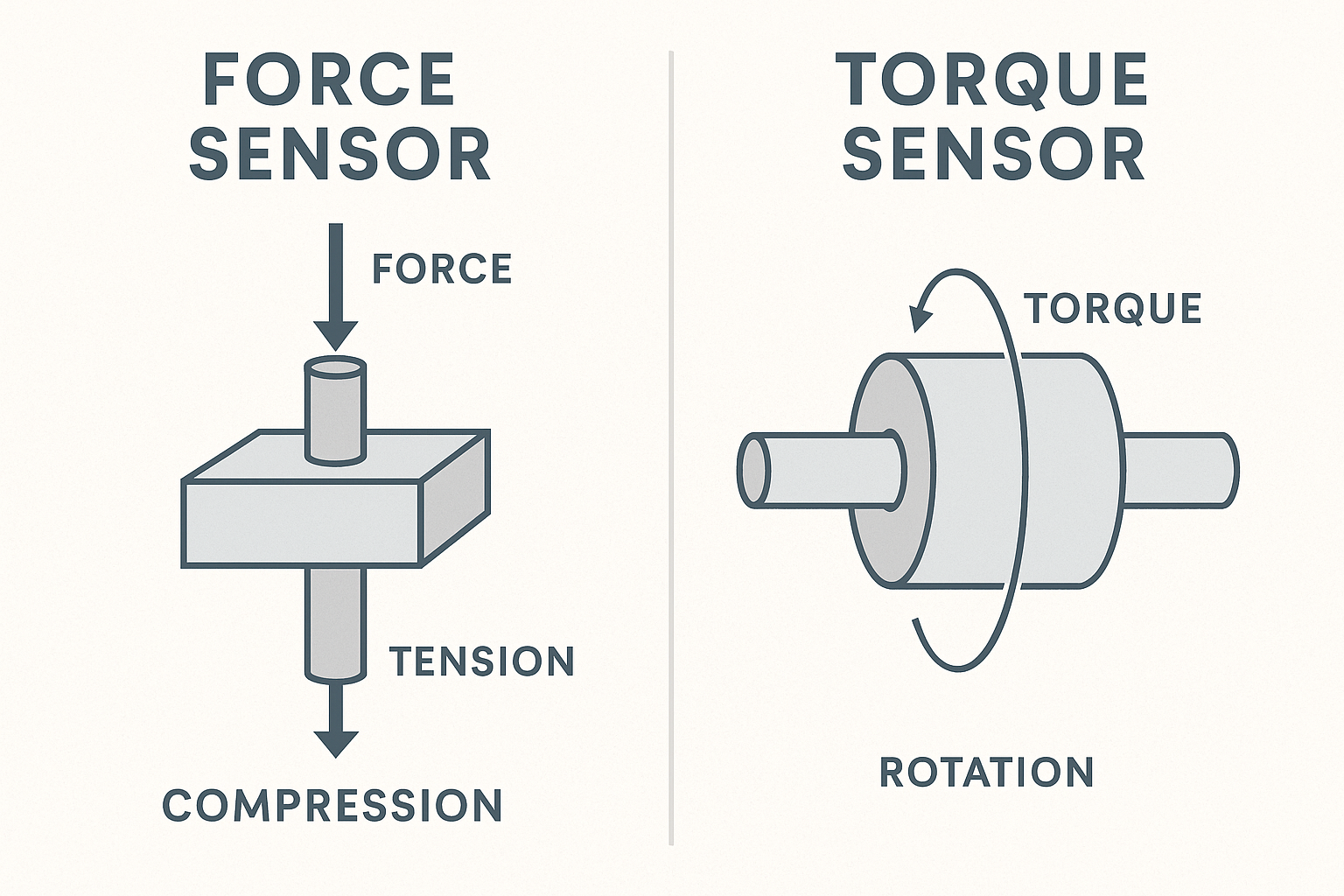

In automation, robotics, and industrial testing, understanding the difference between force and torque sensors is essential for choosing the right measurement tool.

Though both measure mechanical loads, they serve different purposes, operate in distinct ways, and are used in different parts of a system.

This article explains how force and torque sensors differ in principle, structure, application, and selection—so you can make better design and integration decisions.

1. What Is a Force Sensor?

A force sensor measures linear force along a straight line—typically tension (pulling) or compression (pushing). It converts mechanical force into an electrical signal proportional to the load.

📌 Common Measurement Units:

Newtons (N)

Kilograms-force (kgf)

Pounds-force (lbf)

🧰 Typical Applications:

Load cells in weighing systems

Robotic grippers

Press-fit force verification

Structural or material testing

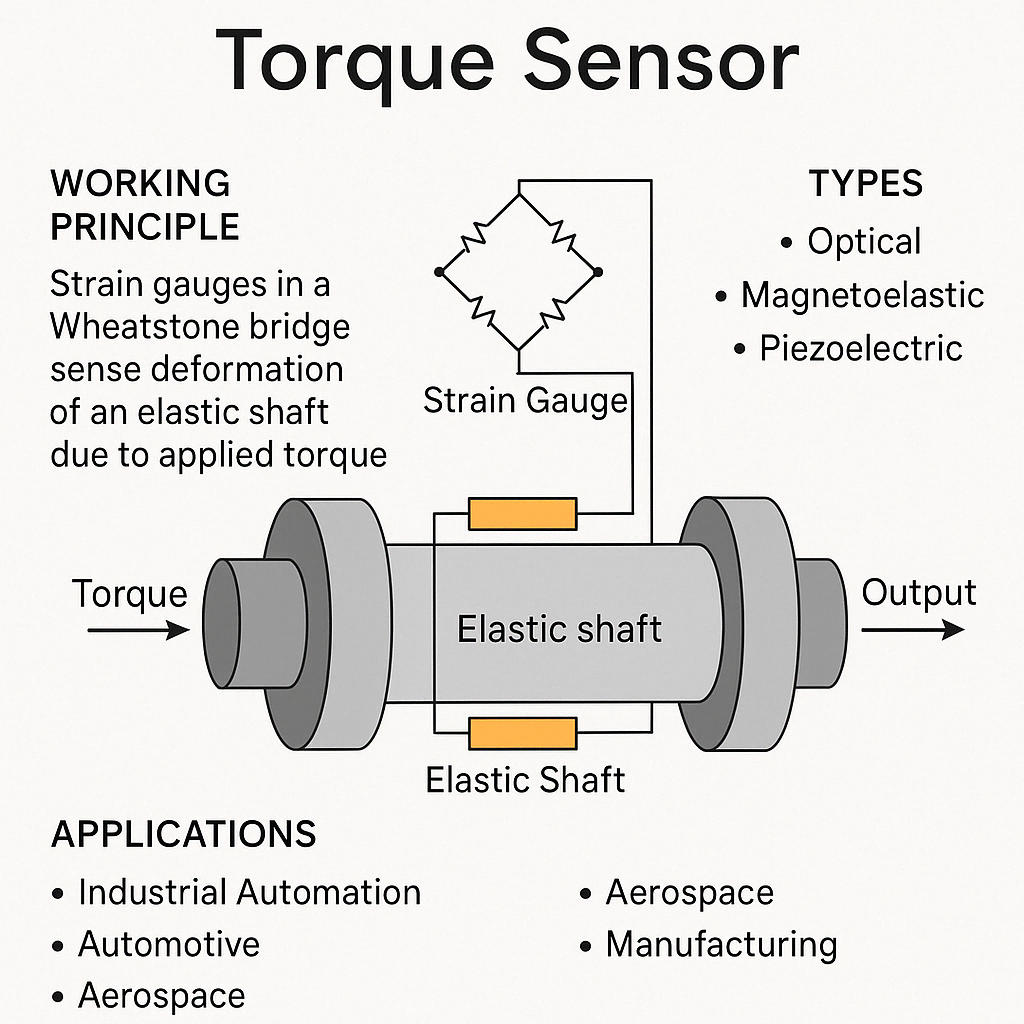

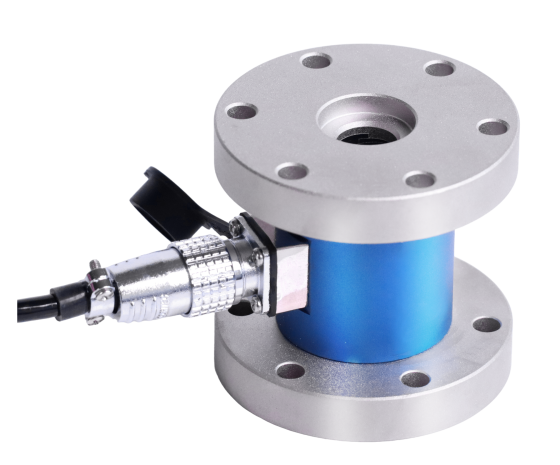

2. What Is a Torque Sensor?

A torque sensor measures rotational force applied about an axis. Also known as a torque transducer, it outputs a signal proportional to the twisting moment.

📌 Common Measurement Units:

Newton-meters (Nm)

Pound-inches (lbf·in)

🧰 Typical Applications:

Electric motor or gearbox testing

Tool torque calibration (e.g., screwdrivers)

Robotic joint monitoring

Automotive engine performance analysis

3. Key Differences at a Glance

| Feature | Force Sensor | Torque Sensor |

|---|---|---|

| Measured Quantity | Linear load (push or pull) | Rotational load (twisting moment) |

| Direction | Single axis (axial) | Rotational around shaft or axis |

| Output Signal | Analog (mV/V, 4–20 mA), Digital | Same; some include encoder outputs |

| Mounting Location | Between structure and load | Inline with shaft or rotating component |

| Typical Form Factor | Beam, S-type, pancake | Shaft-style, flange-type, rotary body |

| Calibration Units | N, kgf, lbf | Nm, oz·in, lbf·in |

4. How to Choose Between Them

| If your application involves… | You need a… |

|---|---|

| Weighing an object | Force Sensor |

| Measuring how tightly a screw is fastened | Torque Sensor |

| Measuring grip strength of a robotic gripper | Force Sensor |

| Monitoring rotational load on a motor shaft | Torque Sensor |

| Pressing or clamping force in assembly equipment | Force Sensor |

| Rotational compliance control in robot joints | Torque Sensor |

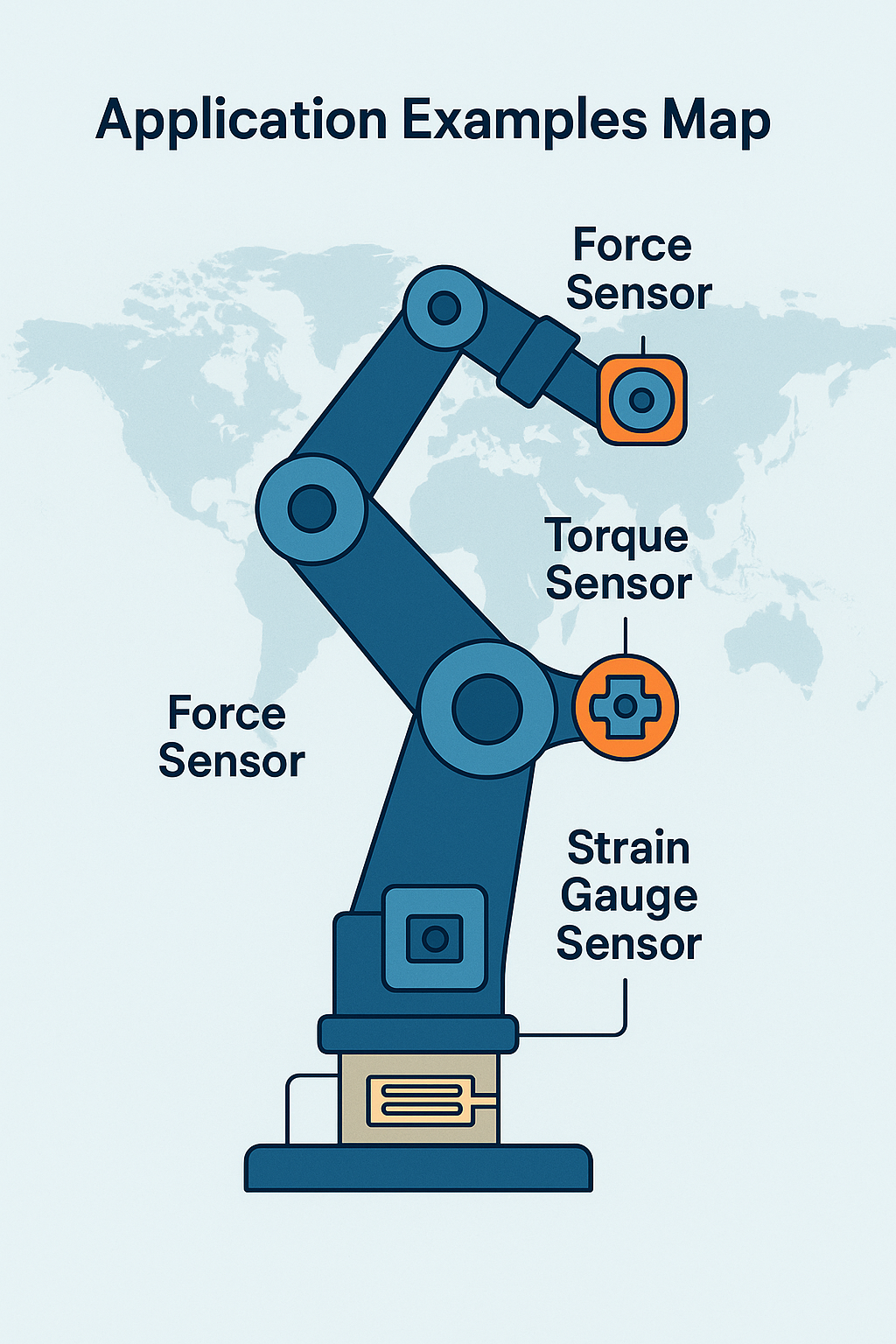

5. Can They Be Used Together?

Absolutely.

In complex systems such as:

Robotic arms

Servo-controlled testing rigs

Surgical robots

…it’s common to use both force and torque sensors simultaneously to monitor and control motion in all degrees of freedom.

6-axis F/T sensors even combine both in one unit—measuring:

Fx, Fy, Fz (forces)

Mx, My, Mz (torques)

6. Final Thoughts

While force and torque sensors both belong to the family of mechanical transducers, their differences lie in the type of mechanical load, installation location, and application focus.

👉 Use force sensors for linear actions like pressing, lifting, or gripping.

👉 Use torque sensors when rotation, twisting, or turning forces need to be measured or controlled.

Choosing the correct one improves not only measurement accuracy but also the safety, performance, and intelligence of your system.