Introduction

As robotics continues to revolutionize manufacturing, healthcare, logistics, and service industries, force sensing has become a critical enabler of safety, precision, and adaptability.

Whether it’s a robot gripping fragile objects, aligning components with tight tolerances, or detecting contact with humans, a properly selected force sensor ensures intelligent, feedback-driven control.

This guide will walk you through the key criteria for selecting the right force sensor for your robotic application.

1. Why Do Robots Need Force Sensors?

Force sensors provide real-time feedback on physical interaction between the robot and its environment. They allow robots to:

Detect and react to contact

Control gripping force to avoid damage

Perform adaptive assembly and part alignment

Maintain consistent pressure in polishing, welding, or gluing

Enable safe human-robot collaboration (HRC)

2. Common Types of Force Sensors in Robotics

| Sensor Type | Typical Use |

|---|---|

| Strain Gauge Load Cells | Gripper force feedback, joint torque monitoring |

| Piezoelectric Sensors | Dynamic force detection, vibration sensing |

| 6-Axis Force/Torque Sensors | Full 3D force/torque feedback at the end-effector |

| Capacitive/Optical Tactile Sensors | High-resolution fingertip or contact surfaces |

📌 The optimal sensor depends on how many degrees of freedom (DOF) and what kind of interaction your robot needs.

3. Key Factors to Consider

✅ Force Range and Sensitivity

Choose a sensor that covers the expected force range with enough resolution for fine control

For delicate object handling, sensors with low-range, high-sensitivity are preferred

For industrial robots, use sensors rated for higher impact or payload forces

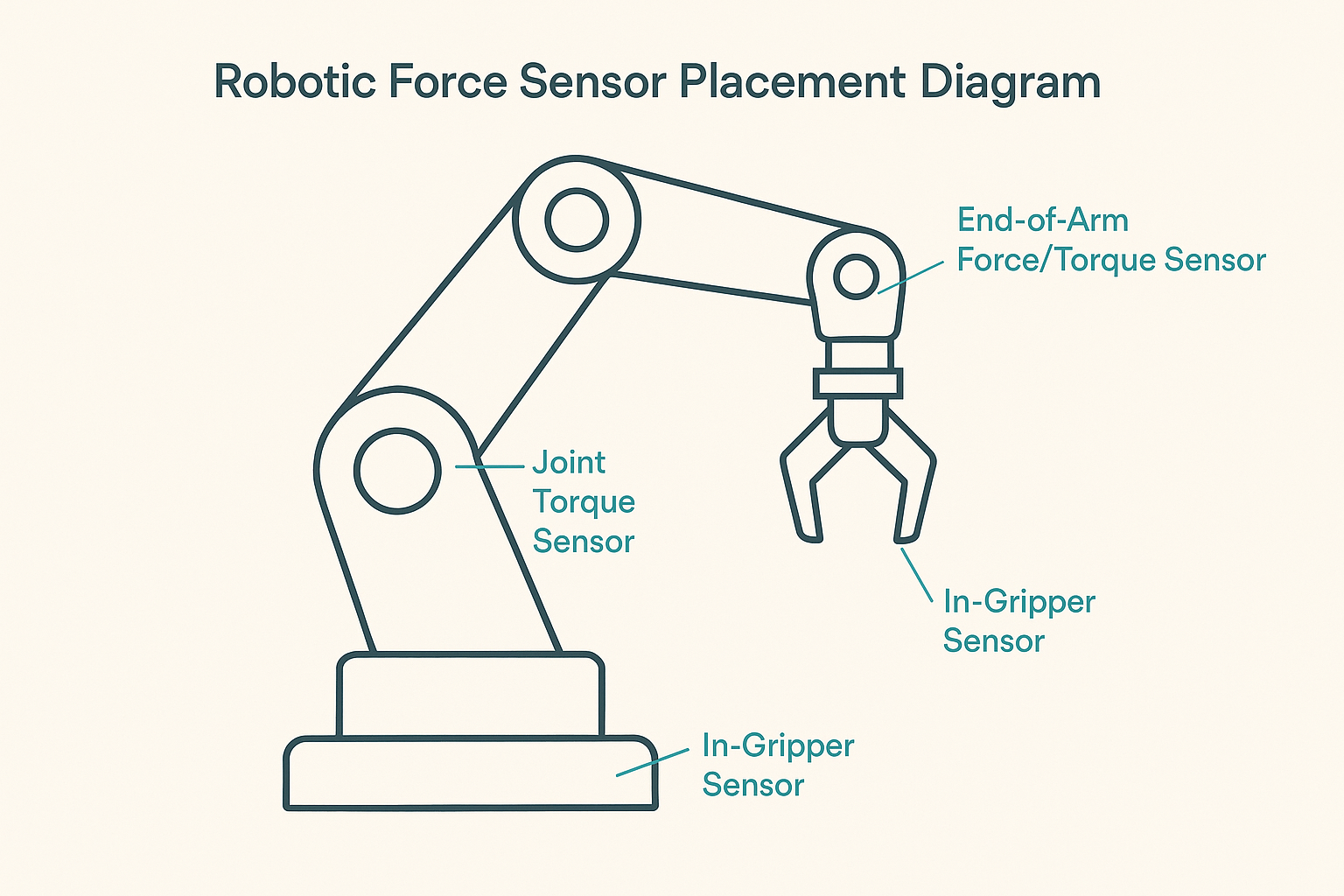

✅ Mounting Location

In-gripper sensors measure grip strength directly

Joint torque sensors provide motion control feedback

End-of-arm 6-axis sensors offer comprehensive contact force data

Make sure the sensor form factor fits your robot’s mechanical design.

✅ Output Signal Type

Analog (mV/V, 0–10V, 4–20mA) for simple integration

Digital (RS485, CAN, EtherCAT) for multi-axis precision control

Match sensor output to your robot controller or PLC input

✅ Dynamic vs. Static Performance

For continuous contact and manipulation, prioritize stability and zero drift

For impact or vibration detection, choose sensors with fast response and high natural frequency

4. Application-Specific Recommendations

| Application | Recommended Sensor Traits |

|---|---|

| Gripping fragile or variable objects | Low-range, compact, analog or digital output |

| Robotic assembly (press-fit, alignment) | High precision, strain gauge or 6-axis torque sensors |

| Human-robot collaboration (HRC) | Soft tactile sensors, overload protection |

| Robotic polishing or sanding | Dynamic force feedback, high-frequency response |

| Surgical or medical robotics | Ultra-miniature, biocompatible sensors with fine control |

5. Environmental and Safety Considerations

Use sealed or IP-rated sensors for dusty or wet environments

Ensure overload protection is built-in or added externally

For mobile or battery-powered robots, prefer low-power, digital-output sensors

Verify compliance with ISO 10218 or ISO/TS 15066 for collaborative safety zones

6. Bonus Tip: Calibration and Software Integration

Choose sensors with factory calibration certificates

Use sensors with available drivers or SDKs for integration into ROS, LabVIEW, or PLCs

Consider sensors with temperature compensation for variable working conditions

Conclusion

Choosing a force sensor for robotics is not just about specs—it’s about understanding the interaction between robot, task, and environment. A well-selected sensor enhances dexterity, increases safety, and unlocks advanced capabilities like compliant control and tactile intelligence.

As robots get smarter, so must their sensors.

Right sensor = Smarter robot.