1. Introduction

Valve selection is a critical aspect of piping system design in chemical processes. The right valve type ensures process efficiency, safety, and longevity of the equipment. This guide outlines the general principles of valve selection and provides practical recommendations for commonly used valve types.

2. General Selection Principles

2.1 Define the Valve Function

Identify the control objective: shut-off, throttling, direction control, backflow prevention.

Determine flow characteristics, system pressure, and required response time.

2.2 Understand Valve Characteristics

Study the structural and functional differences among valve types.

Match valve properties with process requirements (e.g., corrosion resistance, pressure tolerance).

2.3 Select End Connection Type

Threaded (DN ≤50 mm): Easy installation; limited to low-pressure applications.

Flanged: Widely applicable; easy to assemble/disassemble.

Welded: High reliability; suitable for high-temperature and high-pressure applications; limited reusability.

2.4 Choose Appropriate Valve Materials

Base selection on media properties (corrosiveness, temperature, viscosity).

Common body materials: cast iron, carbon steel, stainless steel.

Seal materials: rubber, copper, alloy steel, PTFE (F4).

3. Common Valve Types and Application Guidelines

3.1 Gate Valve

Use: Fully open/close operations with low fluid resistance.

Pros: Minimal pressure loss, suitable for high-pressure/high-temperature.

Cons: Not suitable for flow regulation; slow actuation; high structure height.

Application: Steam, oil, high-temperature fluids; not suitable for coking media.

Selection Tip: Use wedge-type gate valve for coking-prone media.

3.2 Ball Valve

Use: Fast shut-off; good for slurries and viscous media.

Pros: Excellent sealing, low torque, rapid actuation.

Cons: Poor throttling; high torque in large diameters.

Application: Corrosive, high-viscosity, or clean media; emergency shut-off.

Special Notes: Use gear-operated ball valves for DN ≥200 mm.

3.3 Check Valve

Use: Prevent backflow; relies on pressure differential.

Type Selection:

Lift Check Valve (DN ≤40 mm): Horizontal installation only.

Swing Check Valve (DN 50–400 mm): Horizontal or vertical installation.

Buffer/Clamped Check Valve (DN ≥100 mm): For high flow conditions.

Application: Clean fluids, steam, oil; not for dirty or solid-laden fluids.

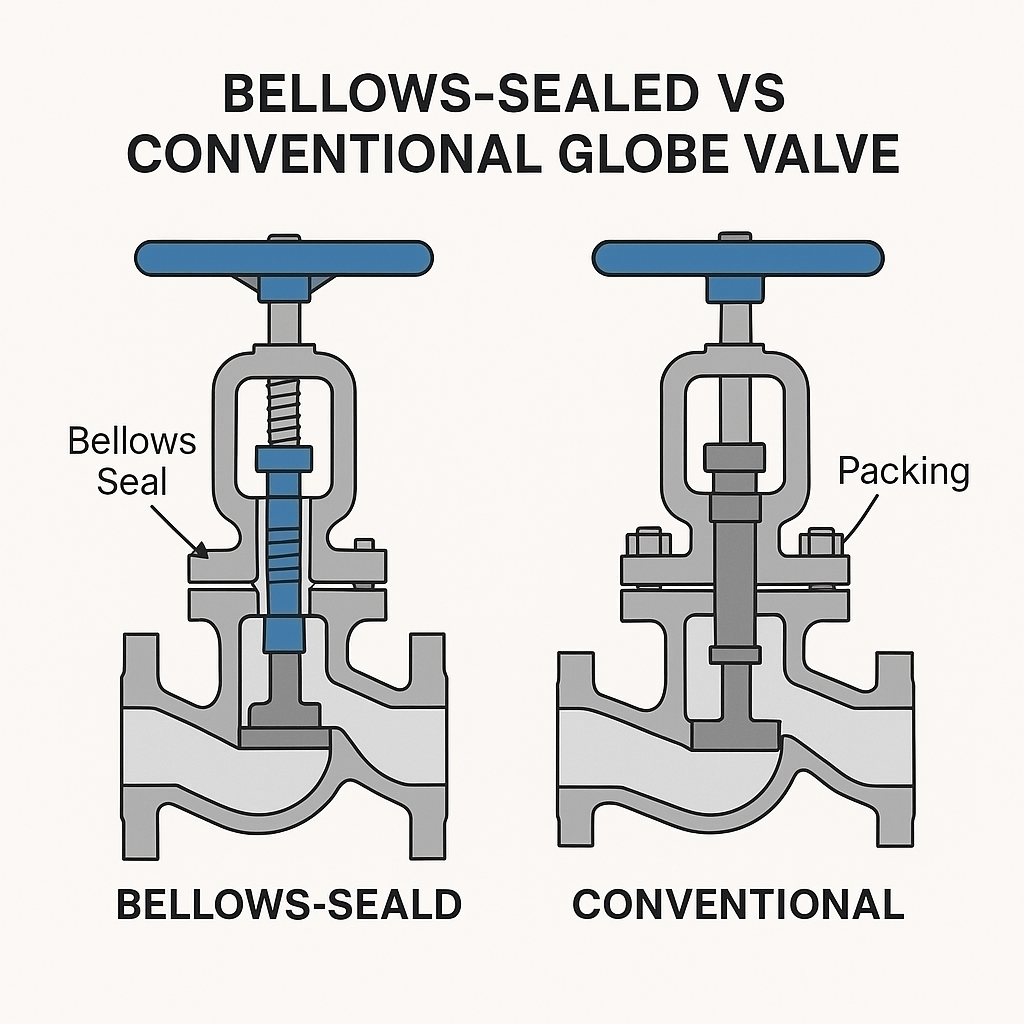

3.4 Globe Valve

Use: Precise flow or pressure control.

Pros: Good sealing; suitable for high-pressure and high-temperature.

Cons: High flow resistance; not ideal for dirty media.

Application: Sampling valves, vacuum systems, small-bore pipelines.

Special Notes: Use bellows-type globe valves for toxic media.

3.5 Throttle Valve

Use: Coarse flow regulation.

Pros: Simple design; cost-effective.

Cons: Poor accuracy; prone to erosion with dirty fluids.

Application: Clean, low-temp, high-pressure systems.

3.6 Butterfly Valve

Use: On/off and throttling service for large-diameter pipes.

Pros: Compact, low cost, quick actuation.

Cons: Limited sealing under high pressure.

Application: Water, oil, non-critical gases; large pipelines.

Selection Tip: Use soft-seal for low temp (< 300°C), low pressure (< 1.0 MPa).

3.7 Plug Valve

Use: Quick shut-off in corrosive/toxic service.

Pros: Bi-directional seal, compact.

Cons: High torque, potential contamination (lubricated type).

Application: Intermittent flow, multiple flow paths.

3.8 Diaphragm Valve

Use: Corrosive or slurry fluids; hygienic applications.

Pros: No leakage; clean separation of actuator and fluid.

Cons: Limited to low pressure and temperature (< 1.0 MPa, < 200°C).

Application: Pharmaceuticals, food, viscous slurries.

4. Key Considerations in Valve Selection

| Factor | Description |

|---|---|

| Fluid Type | Liquid, gas, steam, slurry, corrosive, clean/dirty |

| Valve Function | Shut-off, throttling, non-return, emergency isolation |

| Pressure & Temp | Must meet design conditions of the pipeline system |

| Installation Space | Height, direction, maintenance accessibility |

| Pressure Loss | Evaluate allowable pressure drop vs process need |

| Materials | Corrosion resistance, strength, sealing capability |

6. Conclusion

Proper valve selection requires a thorough understanding of process conditions and valve design characteristics. This guide provides a foundational approach to choosing the appropriate valve based on medium type, pressure/temperature conditions, and control requirements. For detailed project designs, consult manufacturer specifications and industry standards.