Paper, one of the Four Great Inventions of ancient China, remains a cornerstone of modern civilization. Today, the pulp and paper industry is not only essential to national economic development but also critical to environmental and societal progress. Among the many technologies supporting this industry, pressure sensors play a vital role across various stages—from raw material preparation to wastewater treatment.

1. Pressure Sensors in Raw Material Preparation

During the initial stages of papermaking, raw materials such as wood chips or recycled paper are often subjected to high-temperature chemical digestion. This process occurs in environments with elevated pressures and temperatures. Standard pressure sensors may not withstand these harsh conditions, so high-temperature pressure sensors or sensors equipped with cooling fins are recommended.

Illustration 1: Typical Pressure Sensor Placement in Digester Systems

High-temperature-rated sensors offer extended temperature ranges and ensure long-term stability and reliability, even in extreme environments.

2. Pressure Sensors in Pulping and Papermaking

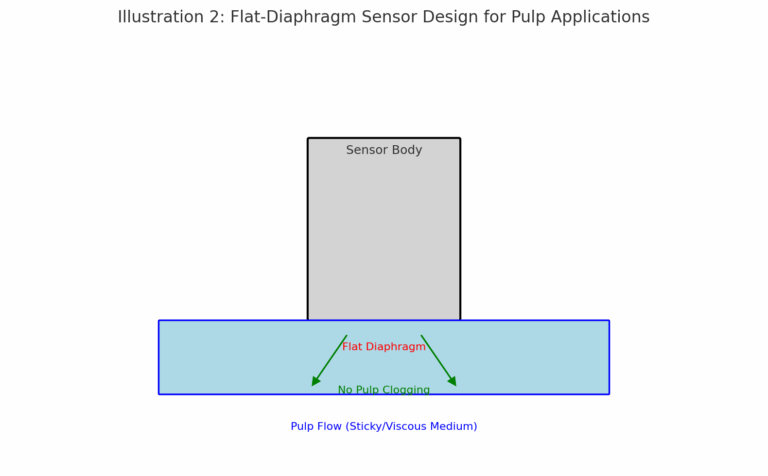

Pulping produces a viscous slurry that can cause clogging or fouling in standard pressure sensors. In this scenario, flat-diaphragm pressure sensors are highly effective.

These sensors:

Prevent clogging from fibrous or sticky pulp

Allow for easier cleaning and maintenance

Improve accuracy in flow or level control

Illustration 2: Flat-Diaphragm Sensor Design for Pulp Applications

Using such specialized sensors helps maintain consistency in slurry flow and ensures better control in downstream papermaking processes.

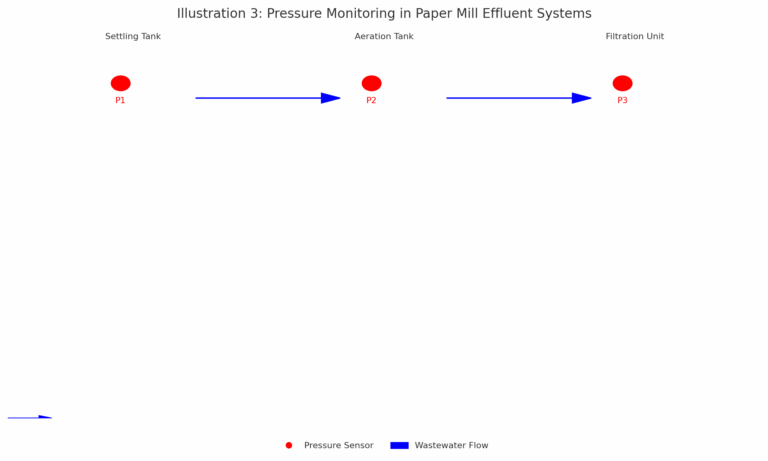

3. Pressure Sensors in Wastewater Treatment

Wastewater treatment is a critical component of the paper production process. Among the commonly used sensors, the 3051-type differential pressure sensor stands out for its precision and versatility.

In wastewater treatment systems, pressure sensors are used to measure:

Liquid level in settling tanks

Flow rate of treatment chemicals

Pressure in filtration and aeration systems

The 3051 sensor, typically made of 316L stainless steel, offers excellent corrosion resistance. It supports real-time configuration adjustments, including:

Remote range setting

Process variable monitoring

Intelligent signal linearization

Illustration 3: Pressure Monitoring in Paper Mill Effluent Systems

These features help ensure accurate and reliable measurement, essential for environmental compliance and operational efficiency.

4. Industry Outlook and Sensor Impact

Driven by the global rise in packaging demand and improving supply-demand dynamics, the pulp and paper market is expanding steadily. The application of pressure sensors enhances production by:

Increasing process speed and control accuracy

Reducing raw material and energy waste

Minimizing equipment downtime

Lowering production costs

In short, pressure sensors contribute to higher paper quality, reduced environmental impact, and enhanced competitiveness in the global market.

Conclusion

As the pulp and paper industry evolves toward intelligent manufacturing and greener processes, the role of pressure sensors becomes increasingly significant. Whether in high-temperature digesters, thick slurry pipelines, or effluent treatment units, choosing the right pressure sensor ensures long-term efficiency, safety, and sustainability.