Introduction

In thermal power generation, maintaining appropriate steam parameters is critical not only for system safety but also for operational efficiency. Among these parameters, superheated steam temperature stands out as a key indicator that must strike a balance between economic performance and system integrity. While drum pressure is important for safety, superheated steam temperature directly impacts both the thermal efficiency of the unit and the lifespan of critical components.

1. The Economic Impact of Steam Temperature

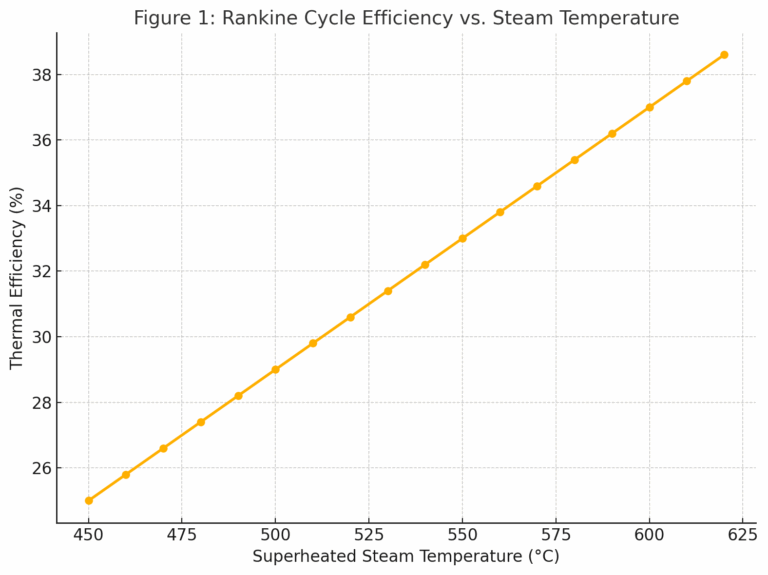

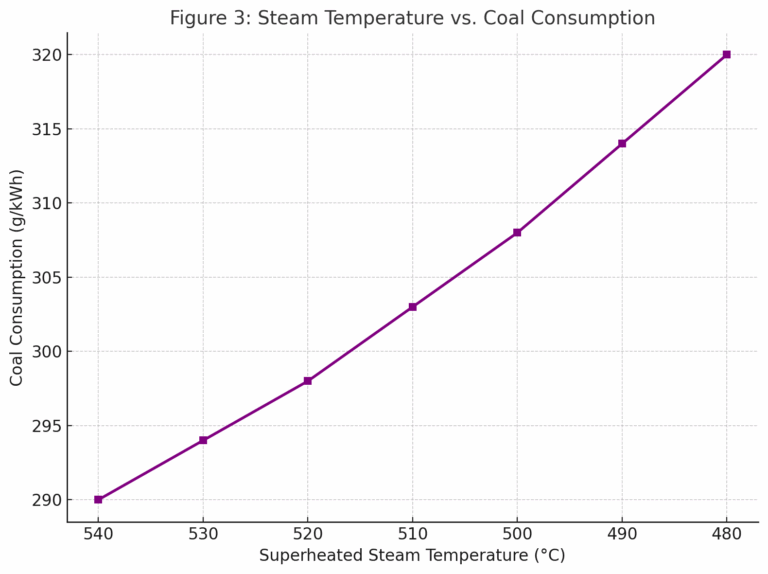

According to the Rankine cycle principle, the higher the working fluid temperature, the greater its ability to do work, and thus, the higher the thermal efficiency of the system. Even small temperature deviations can significantly influence energy consumption:

For subcritical and supercritical power units, a 10°C drop in superheated steam temperature can lead to an increase of 1.0 grams of standard coal per kilowatt-hour (g/kWh) of electricity generated.

For reheated steam, the same temperature drop may increase coal consumption by 0.8 g/kWh.

Another reference states: for every 5°C decrease, overall thermal efficiency may drop by approximately 1%.

These numbers may vary depending on the unit capacity and specific design, but the economic trend remains consistent: lower steam temperatures lead to higher fuel consumption and reduced efficiency.

2. The Safety Risks of Excessive Steam Temperature

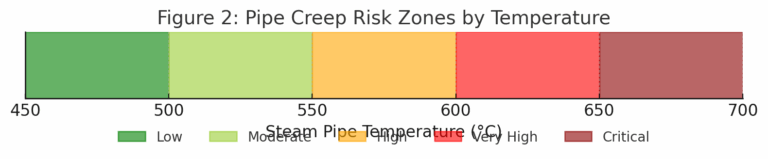

Despite the temptation to raise steam temperature for better efficiency, there is a strict upper limit dictated by material constraints. Steam pipes and components have limited temperature tolerance:

Operating at temperatures higher than design limits can induce high-temperature creep, a slow deformation of metal under heat and stress, eventually leading to pipe rupture or failure.

Even if immediate damage does not occur, prolonged exposure to elevated temperatures significantly shortens the lifespan of steam pipes and turbines.

Therefore, stable and precise steam temperature control is a dual requirement: improving economic efficiency without compromising safety.

3. Why Steam Temperature Control Is More Demanding Than Drum Level Control

In contrast to drum water level—where maintaining values within a safe range is sufficient—superheated steam temperature demands continuous precision:

A slightly lower temperature reduces efficiency and increases operating cost.

A slightly higher temperature introduces severe safety risks.

To ensure both performance and protection, steam temperature must be kept as stable as possible, ideally at the upper edge of the safety margin. However, this is extremely difficult due to factors such as:

Load fluctuations

Fuel composition changes

Ambient temperature and pressure variation

Heat transfer dynamics within the boiler

Thus, while theoretically, it is possible to raise the setpoint to improve efficiency, in practice, maintaining a flat and optimal temperature curve remains a significant technical challenge.

4. Conclusion and Outlook

In thermal power systems, the superheated steam temperature is not just another process variable—it is a strategic lever for balancing cost-efficiency with equipment longevity and plant safety. Controlling it with precision demands robust instrumentation, real-time feedback control systems, and continuous operator attention.

While technological advancements—such as predictive control algorithms and AI-based optimization—are making steam temperature control more manageable, the fundamental challenge remains:

“Too low wastes fuel. Too high risks lives. Precision is not optional—it is essential.”