1. What Is Temperature and Pressure Compensation?

Temperature and pressure compensation refers to the process of correcting flow measurements by accounting for real-time temperature and pressure deviations from standard conditions. These two factors—temperature and pressure—have significant influence on gas and steam flow readings. To achieve accurate flow measurement results, it is essential to apply compensation formulas that adjust for these variations.

Most instruments display flow values under standard conditions (e.g., 25°C and 1 atm). However, actual field conditions typically vary, necessitating automatic compensation to correct the raw measurements.

2. Why Is Compensation Necessary for Steam?

Steam, being a compressible fluid, is sensitive to changes in temperature and pressure. Specifically:

When temperature increases or pressure decreases, steam expands—causing the volumetric flow measurement to be higher than actual.

When temperature decreases or pressure increases, the steam compresses—resulting in a lower volumetric reading.

Since steam is usually billed in mass flow units (e.g., tons/hour), and steam density changes with both temperature and pressure, compensation is essentially a density correction process. Accurate steam flow measurement requires real-time calculation of density based on current operating temperature and pressure.

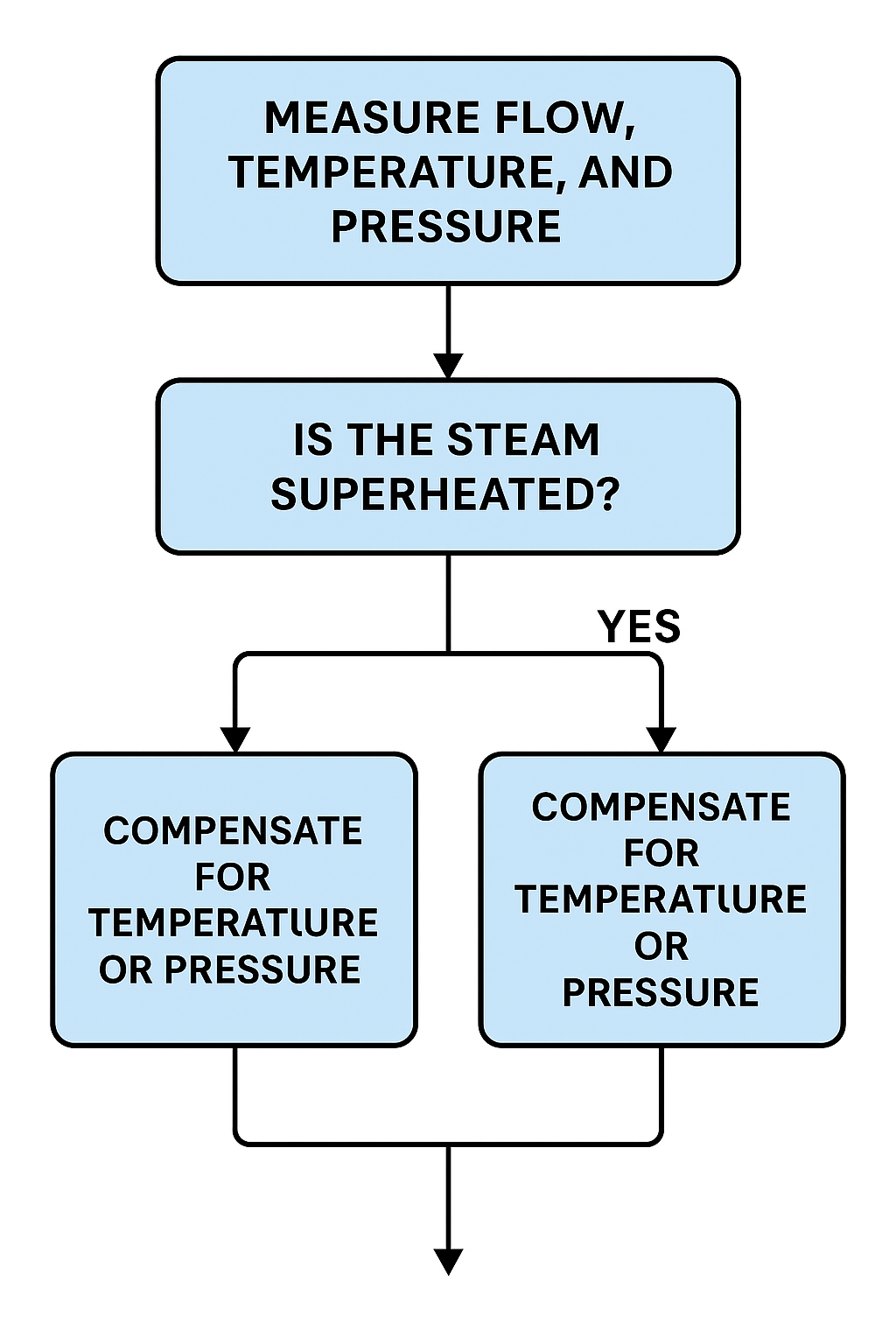

3. Where Is Temperature and Pressure Compensation Required?

| Application Scenario | Compensation Needed | Remarks |

|---|---|---|

| Gas flow measurement | Temperature + Pressure compensation | Gases expand/compress under different conditions, affecting volume flow. |

| Superheated steam | Temperature + Pressure compensation | Mass flow varies as steam density changes with both parameters. |

| Saturated steam | Temperature or Pressure (single) | Density is uniquely determined by either temperature or pressure. |

| Liquid measurement | Usually temperature only | Pressure can often be ignored if <5 MPa. |

4. How Is Compensation Implemented?

The implementation method depends on both the type of steam and the instrumentation used:

Saturated Steam: There exists a fixed relationship between temperature and pressure. Measuring either parameter allows calculation of the other and the corresponding steam density. Thus, only one parameter is needed for compensation.

Superheated Steam: Both temperature and pressure must be measured simultaneously. Steam density is then determined via steam tables or formulas (e.g., IAPWS-IF97 or other thermodynamic equations).

Stable Conditions: In some stable, non-critical applications, fixed density values may be used based on assumed operating conditions—but this method introduces significant errors if the conditions fluctuate, and is not recommended.

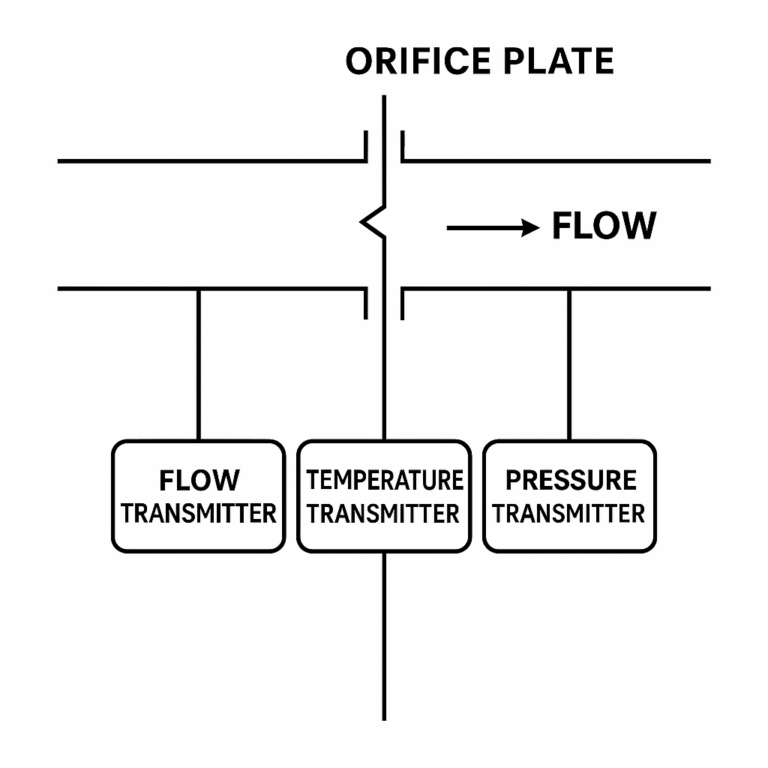

5. Instrumentation Considerations

Typical flow meters used for steam measurement include:

Vortex Flow Meters

Differential Pressure Flow Meters (Orifice Plate, Venturi, etc.)

Ultrasonic Flow Meters

Mass Flow Meters (Coriolis type)

Instruments used for temperature and pressure input may include:

RTDs or Thermocouples (for temperature)

Pressure Transmitters (for pressure)

These values are processed by the flow computer or DCS system to calculate compensated mass flow in real-time.

6. Summary

Temperature and pressure compensation is essential for achieving accurate steam flow measurements. It corrects the effects of compressibility by dynamically adjusting for density changes, ensuring billing and process control decisions are based on reliable data.

Whether dealing with saturated or superheated steam, compensation strategies must be selected based on the fluid characteristics and system requirements. Investing in proper instrumentation and applying the correct compensation model enhances both accuracy and operational efficiency.