1. Overview

Bar-type flow meters, also known as insertion differential pressure flow meters, operate based on Bernoulli’s principle. By measuring the differential pressure generated across the sensor (total pressure minus static pressure), they calculate flow velocity and volume. Their simple structure, low pressure loss, and ease of installation make them ideal for large-diameter pipelines (typically DN300 and above) across gas, liquid, and steam applications.

2. Major Types and Key Parameter Comparison

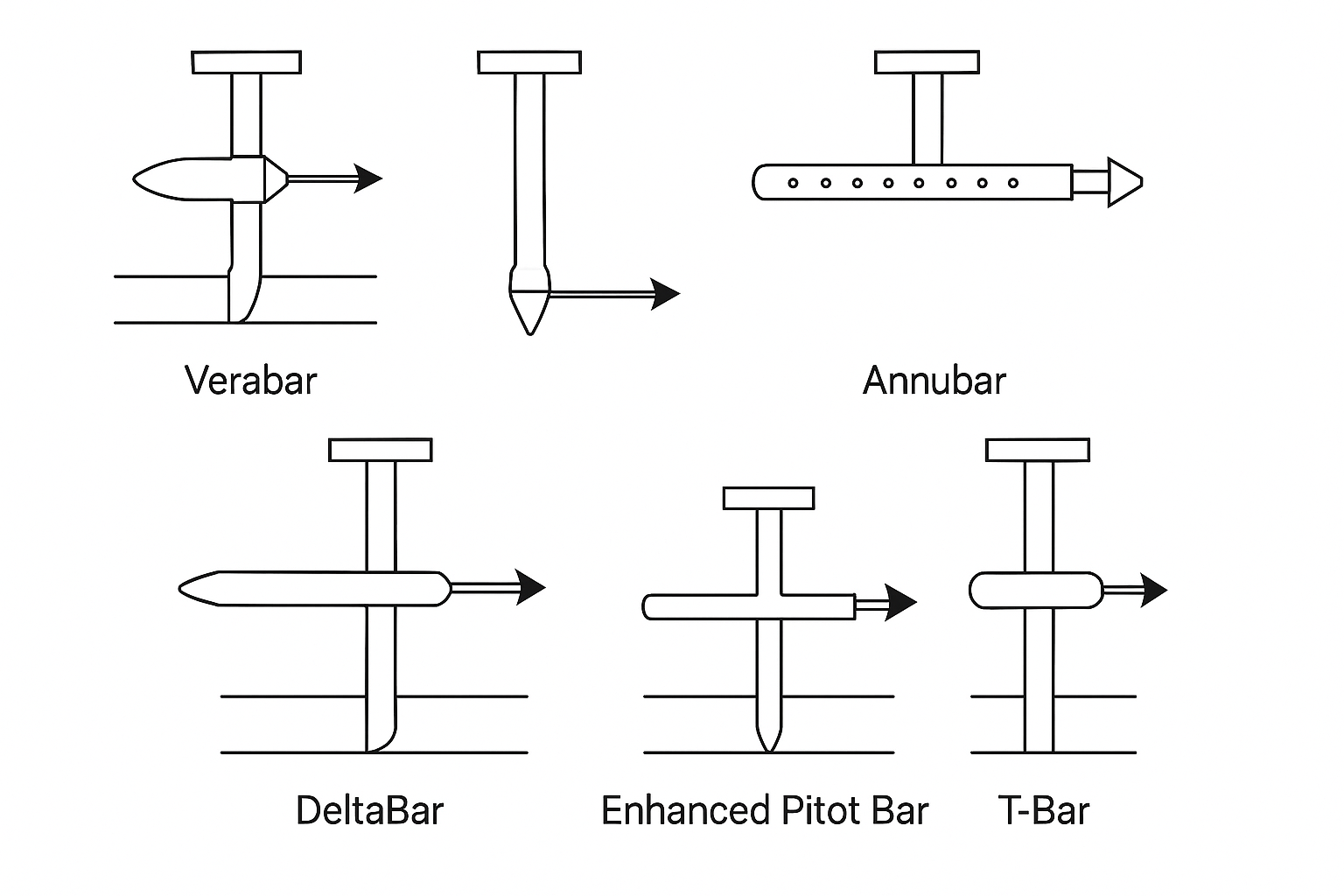

2.1 Verabar

Principle: Bullet-shaped cross-section with multiple pressure ports and dynamic compensation algorithm.

Accuracy: ±1.0% (typical); error increases to ±15–20% at <0.8 m/s.

Turndown Ratio: 10:1 (volumetric), 8:1 (mass).

Size Range: DN38–9000.

Media Compatibility: Natural gas, compressed air, steam, low-viscosity liquids (≤10 cP).

Temp/Pressure: Up to 550°C, 40 MPa.

Installation: Requires 10D/5D straight pipe; anti-block design.

Price: Approx. RMB 80,000–120,000 for DN800.

2.2 DeltaBar

Principle: Utilizes wake vortex shedding with dual-signal fusion for low-velocity stability.

Accuracy: ±0.2%–0.5% (typical); ±8–12% at 0.6 m/s.

Turndown Ratio: 30:1 (bidirectional).

Size Range: DN3–9000.

Media Compatibility: High-pressure steam (≤25.5 MPa), corrosive fluids, two-phase flow.

Temp/Pressure: -200°C to 1240°C, up to 68 MPa.

Installation: On-line insertion supported.

Price: Approx. RMB 70,000–100,000 for DN800.

2.3 Annubar

Principle: Multi-port pressure sensing with internal averaging chamber.

Accuracy: ±1.0–5.0% (varies by condition); poor low-velocity performance.

Turndown Ratio: 10:1 (volumetric), 8:1 (mass).

Size Range: DN50–12000.

Media Compatibility: Heavy oil (≤30 cP), dirty gas (with purge system).

Temp/Pressure: Up to 450°C, 20 MPa.

Installation: Moderate anti-clog capability; requires routine cleaning.

Price: Approx. RMB 120,000–180,000 for DN800.

2.4 Enhanced Pitot Bar

Principle: 8–12 pressure ports with AI dynamic compensation for improved sensitivity.

Accuracy: ±5–10% at 0.5 m/s.

Turndown Ratio: 50:1.

Size Range: DN50–5000.

Media Compatibility: Wet steam (80%–95% dryness), requires integrated humidity sensor.

Temp/Pressure: Up to 650°C, 32 MPa.

Installation: 3D upstream pipe required; maintenance every 6 months.

Price: Approx. RMB 40,000–80,000 for DN800.

2.5 T-Bar

Principle: Symmetrical T-bar design, vibration-resistant for disturbed flows.

Accuracy: ±1.5% (typical); >30% error at <2 m/s.

Turndown Ratio: 5:1.

Size Range: DN300–3000.

Media Compatibility: High-pressure steam, particulate-laden gas (with wear-resistant coating).

Temp/Pressure: Up to 500°C, 38 MPa.

Price: Approx. RMB 50,000–80,000 for DN800.

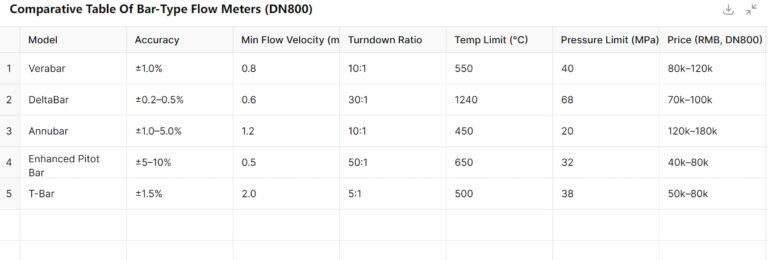

3. Summary Comparison Table (Proposed Illustration)

Suggested Diagram: Tabular chart comparing:

Accuracy

Minimum working flow velocity

Turndown ratio

Pipe size range

Pressure/temperature limits

Maintenance needs

Cost (DN800 reference)

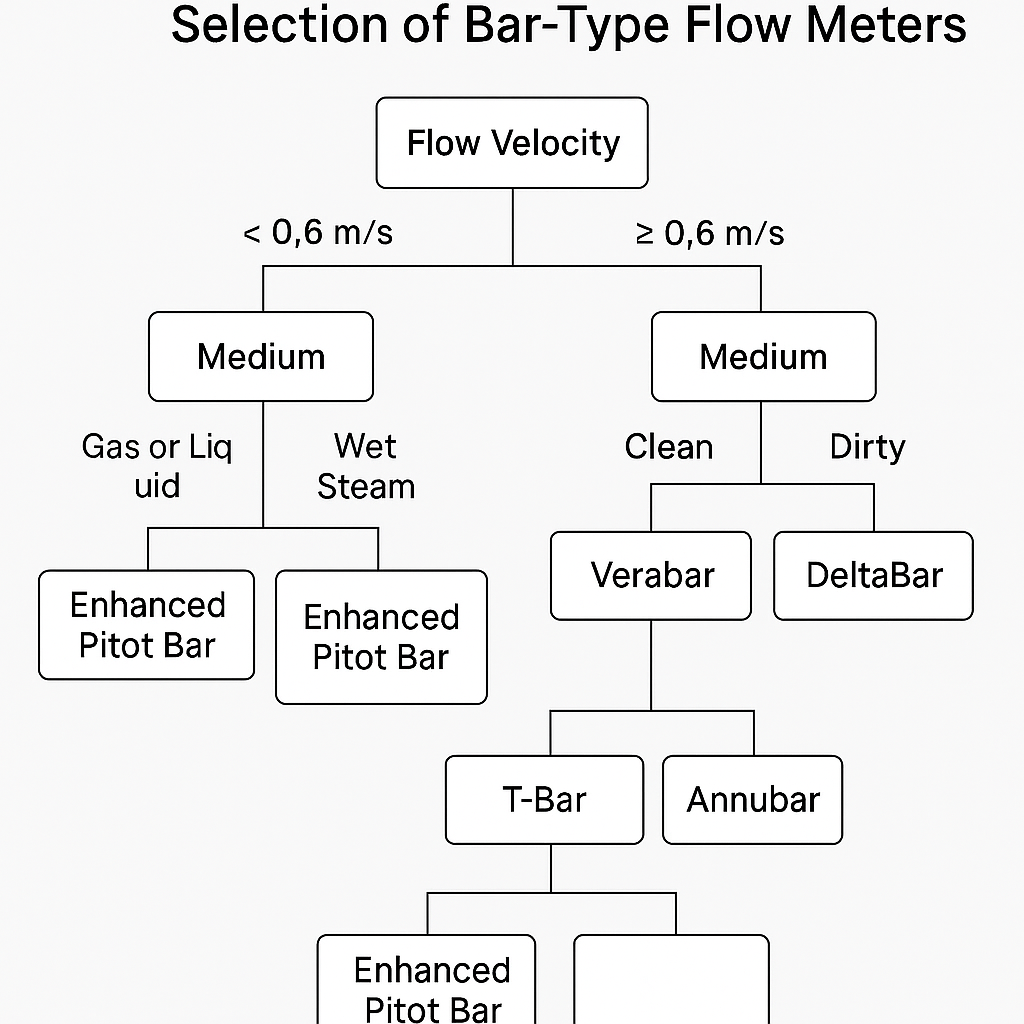

4. Selection Guidelines

Low-Velocity Applications (<0.6 m/s)

Best Option: Ultrasonic flow meters (±3–5% accuracy), high cost (RMB 150,000–250,000).

Alternative: Enhanced Pitot Bar + AI compensation (±5–10%), paired with high-end transmitter (e.g., Rosemount 3051S).

Typical Steam Flow (0.6–10 m/s)

Cost-effective: DeltaBar (balanced performance), Enhanced Pitot (20–30% cheaper).

High-accuracy: Annubar (used in trade settlement), higher maintenance expected.

High-Vibration / Dirty Media

Robustness: T-Bar or V-cone flow meters.

Anti-Clogging: Verabar (bullet-head design) or DeltaBar (self-drain).

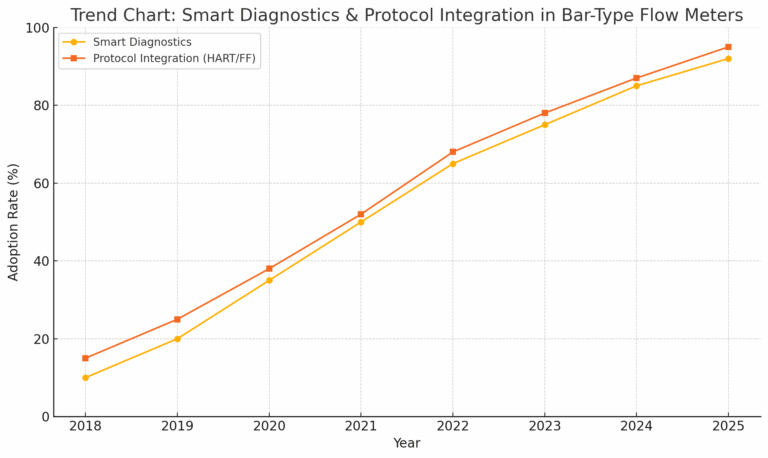

5. Technology Trends

Smart Features: Integrated STM32H7-class edge chips for real-time filtering, offloading DCS.

Sensor Fusion: Coupling with thermal mass or humidity sensors for two-phase flow precision.

Material Upgrades: Ceramic or Hastelloy coatings for extended life in corrosive conditions.

Protocol Standardization: HART, FF, etc. for remote diagnostics and configuration.

6. Conclusion

Choosing the right bar-type flow meter requires balancing accuracy, turndown ratio, media type, and budget.

DeltaBar: Best for large-diameter and high-pressure systems.

Enhanced Pitot: Excellent cost-performance for low-velocity needs.

Verabar and Annubar: Respectively suited for standard and precision trade applications.

With the rise of smart instrumentation and advanced materials, bar-type meters will continue to evolve as key tools in modern industrial flow measurement.