Chemical plants are often regarded as highly automated systems. This is not just a fact; it is a necessity driven by the inherent complexity and uncertainty of chemical processes. The process control systems in these plants rely heavily on feedback mechanisms, particularly the Proportional-Integral-Derivative (PID) control loop, which plays a central role in managing plant operations. In this article, we will explore why chemical plants require such high levels of automation, and why PID control is the dominant method in process control.

The High Level of Automation in Chemical Plants

Chemical plants are dynamic environments where continuous and complex processes take place. The automation in these plants is not just a technological preference but a necessity for several reasons:

Complex Processes and Dynamic Behavior: Chemical processes are influenced by a multitude of variables, including temperature, pressure, flow, and chemical composition. These variables are often subject to fluctuations, making it challenging to achieve consistency. Automation is required to continuously monitor and adjust these parameters in real-time to ensure the stability of the plant and its operations.

Uncertainty in Plant Operations: One of the key factors that contribute to the high automation level is the uncertainty inherent in chemical plants. Non-linearities in valves, changes in pipeline characteristics, variations in material properties, and unpredictable external disturbances all contribute to the complexity of maintaining optimal plant performance. It is difficult to model all these variables accurately, which makes automation essential for maintaining stability and minimizing risks.

Safety and Efficiency: High automation levels are also necessary to ensure the safety of the plant. By automatically adjusting parameters based on real-time data, automation helps prevent dangerous situations caused by sudden process deviations. Furthermore, automation improves the overall efficiency of the plant by reducing manual interventions and minimizing human errors.

The Role of PID Control in Process Control

In process control, one of the most commonly used methods is feedback control, and the PID control loop is the most widely applied technique. But why is PID so prevalent in the chemical industry?

Why Feedback Control is Essential

Feedback control involves continuously monitoring the output of a process and making adjustments to keep the process variables within a desired range. If the system’s output deviates from the desired value, the feedback control mechanism corrects the error.

This is particularly useful in chemical plants, where variables such as flow, temperature, and level can change unexpectedly due to fluctuations in the process. Feedback control systems offer two significant benefits:

Reduction of Uncertainty: By continually detecting and correcting deviations from the desired setpoint, feedback control systems reduce the uncertainty in the process. This allows the plant to operate with greater consistency, even in the face of fluctuating input conditions and disturbances.

Improvement of Performance: Feedback control not only stabilizes the system but also enhances performance. The system can maintain optimal conditions and respond to disturbances more effectively, increasing process efficiency and product quality.

Why PID Control is So Common

PID control, a type of feedback control, is particularly favored in chemical plants because of its simplicity and effectiveness. It is a three-parameter algorithm consisting of:

Proportional (P): The proportional term responds to the current error. The greater the error, the greater the corrective action.

Integral (I): The integral term accounts for accumulated errors over time and helps eliminate long-term bias.

Derivative (D): The derivative term predicts future errors based on the rate of change, allowing the system to respond more proactively.

PID control is widely used because of its simplicity and ability to handle complex, dynamic processes efficiently. Despite being a simple algorithm, PID can effectively manage many chemical processes, such as flow control, temperature regulation, and liquid level control, in a wide variety of applications.

Handling Non-Linearity and Uncertainty with PID

The reason why PID is so effective in chemical plants is its ability to deal with the inherent non-linearity and uncertainty of the processes. For example, controlling flow in a chemical plant involves dealing with non-linearities in valves and changes in pipeline characteristics. These dynamics are difficult to model accurately, but PID control can compensate for these uncertainties by continuously adjusting the output based on real-time feedback.

Unlike more complex control systems that rely on detailed models of the process, PID control simplifies the task by focusing on deviations from the desired setpoint and adjusting accordingly. This simplicity makes PID not only easy to implement but also cost-effective.

Limitations of PID and the Need for More Advanced Control Methods

While PID control is highly effective in many cases, there are situations where more advanced control strategies are needed:

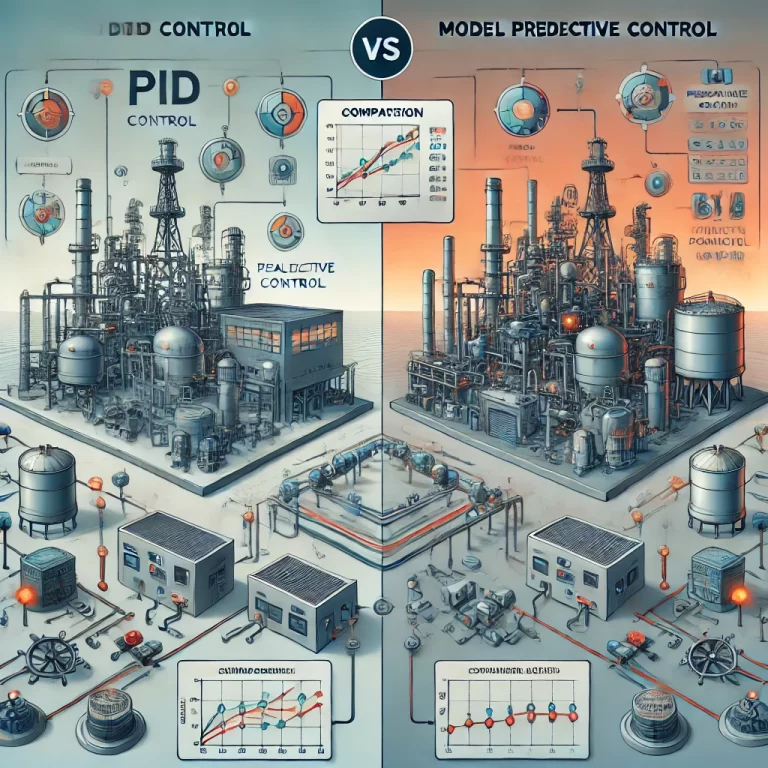

When Process Characteristics Change: In some cases, the process may shift, and the optimal operating point may no longer be valid. In these instances, more advanced control techniques, such as Model Predictive Control (MPC), may be needed to adjust for the new conditions and ensure the process remains within safe operating limits.

Handling Multivariable Systems: When dealing with processes that have multiple interdependent variables, PID may struggle to maintain optimal performance. This is where multi-variable control comes into play, allowing for better management of processes that involve complex interactions between variables.

PID Tuning and Real-World Application

In real-world industrial applications, tuning the PID controller is crucial to ensure optimal performance. Tuning involves adjusting the proportional, integral, and derivative constants to match the specific dynamics of the process. One widely used method is the Lambda tuning method, which simplifies the model of the controlled system to a first-order process with pure delay, making it easier to apply PID control effectively.

However, the simplicity of PID tuning comes at a cost: while it is easy to implement, it often cannot provide the precise control that a more detailed model-based approach would offer. This is why, in some applications, engineers opt for more complex control methods when dealing with systems that require high precision.

Conclusion: The Necessity of Automation and PID Control in Chemical Plants

The automation in chemical plants, driven by feedback control systems like PID, is essential due to the high level of uncertainty and complexity inherent in these processes. PID control, with its simplicity and effectiveness, allows operators to maintain stability and improve performance, even when dealing with unpredictable conditions.

While PID control is sufficient for many applications, there are situations where advanced methods like Model Predictive Control are necessary to handle changing process dynamics and optimize performance. Nonetheless, the ongoing reliance on PID in chemical plants highlights the enduring importance of feedback control in industrial automation.

By understanding and utilizing these control systems, chemical plants can continue to enhance safety, efficiency, and performance, even in the face of increasing complexity and uncertainty.