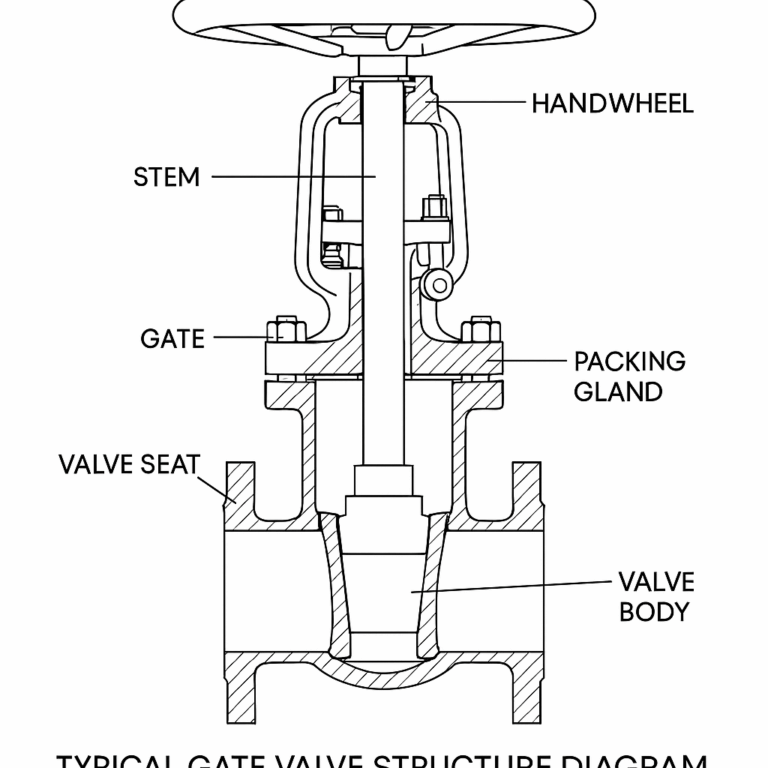

1. Overview of Gate Valve Structure

Gate valves are widely used in industrial sectors such as petrochemicals, power stations, long-distance pipelines, and marine applications. They control the flow of media by moving a gate (wedge or parallel plate) between the valve seats to open or close the passage. A typical gate valve is composed of the valve body, valve seat, gate, stem, bonnet, packing gland, stem nut, and handwheel.

Illustration 1: Typical Gate Valve Structure Diagram

Gate valves are categorized into two major types based on gate structure:

Wedge Gate Valves: The sealing surface is inclined, relying on the wedge force for closure.

Parallel Gate Valves: The sealing surfaces are parallel, relying on spring mechanisms or fluid pressure for sealing.

They are further divided into:

Rising Stem (OS&Y): The stem moves with the gate; the stem position indicates the valve status.

Non-rising Stem: The stem remains stationary; only the gate moves internally.

2. Common Causes of Gate Valve Leakage

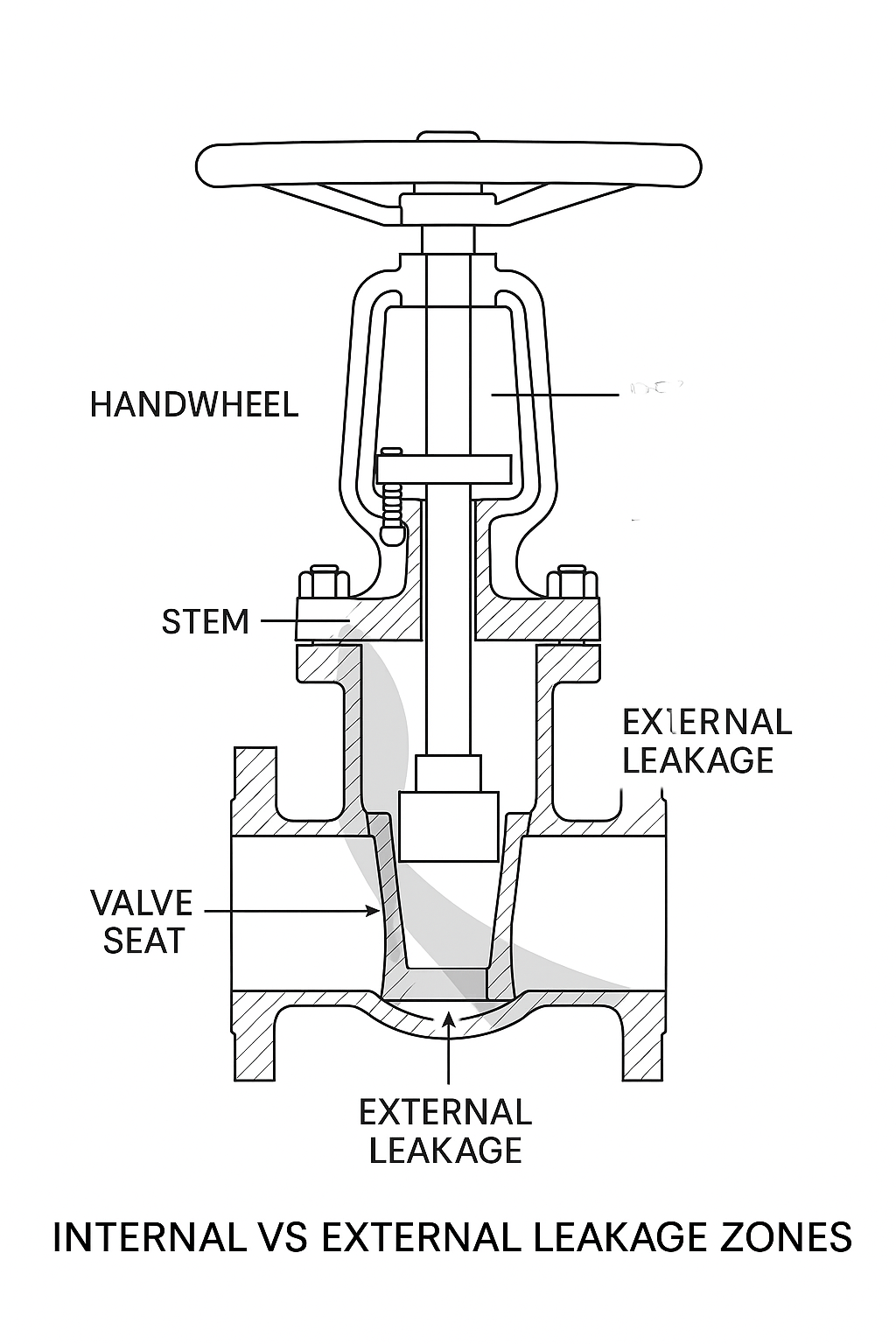

Gate valve leakage can be classified into internal leakage (leakage across closed gate) and external leakage (leakage through valve body or stem). Major causes include:

2.1 Low Machining Precision of the Wedge Seal

There are two main types of wedge seals:

Metallic (hard seal)

Composite graphite (soft seal)

If machining precision is poor, gaps may remain between the gate and seat, leading to internal leakage.

2.2 Unstable Operating Conditions

Frequent pressure or temperature fluctuations during operation can cause deformation of the seal ring, leading to gradual increase in internal leakage.

2.3 Poor Maintenance Quality

If impurities remain on sealing surfaces during reassembly, they can scratch the seat during operation and form leak paths.

2.4 Corrosion of the Sealing Ring

Media may corrode the sealing ring over time. Material hardness, corrosion resistance, and plastic deformability under load must be considered during design.

2.5 Improper Operation of Actuator

If the actuator fails to drive the valve to the fully open or fully closed position, it results in incomplete sealing and internal leakage.

2.6 Casting Defects in Valve Body

Common defects such as porosity, inclusions, cracks, or sand holes can cause external leakage if not identified and repaired before installation.

Illustration 2: Common Internal vs. External Leakage Locations

3. Remedial Measures for Leakage

3.1 Increase Bolt Preload Force

Tightening the valve body cover bolts increases preload on the sealing components, promoting plastic deformation to fill micro-gaps. If this does not reduce leakage, stop further tightening to avoid damage.

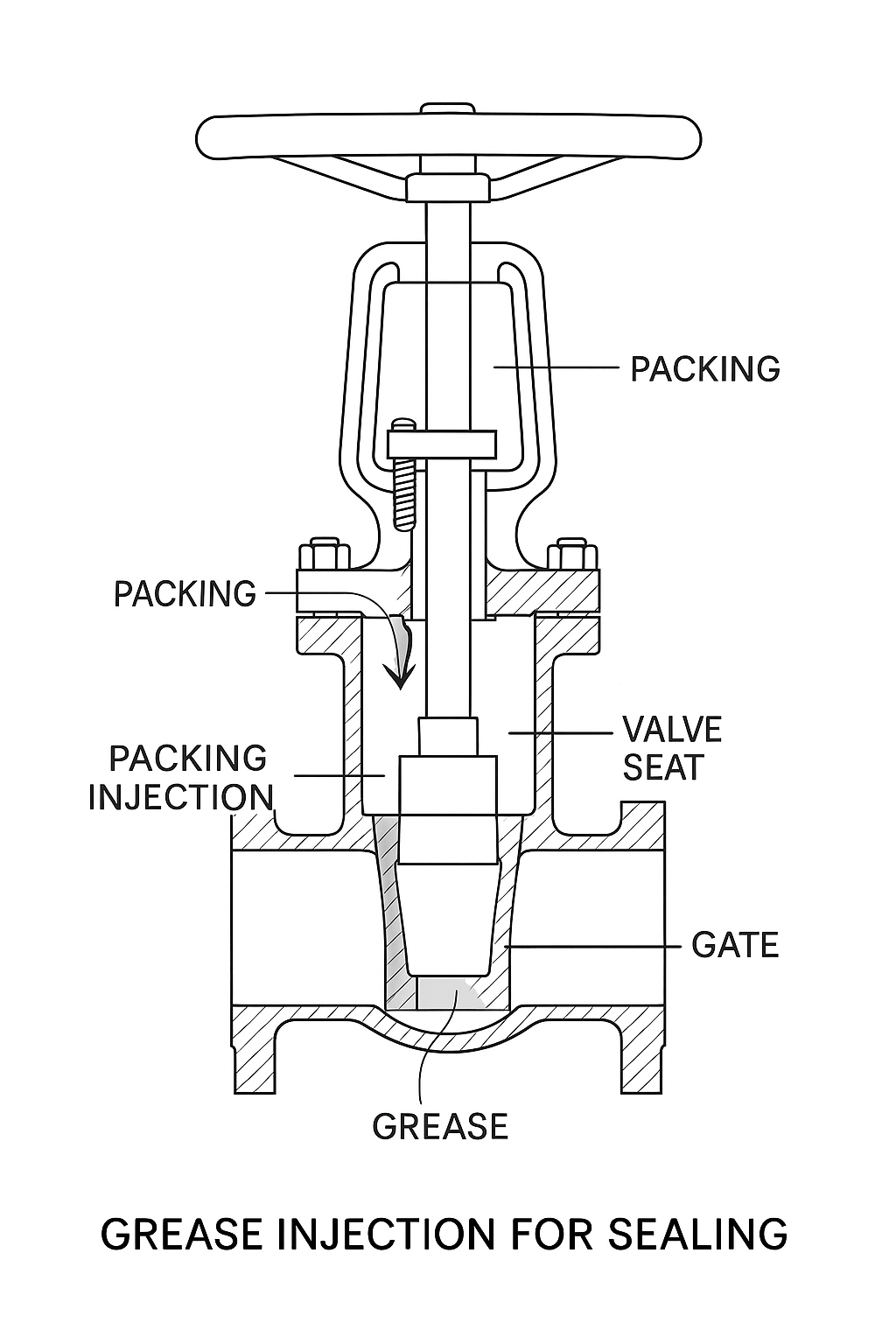

3.2 Injecting Sealant via Grease Port

For minor leakage, sealing grease can be injected through a dedicated port to temporarily restore sealing, allowing time for scheduled repair.

Illustration 3: Sealant Injection Procedure

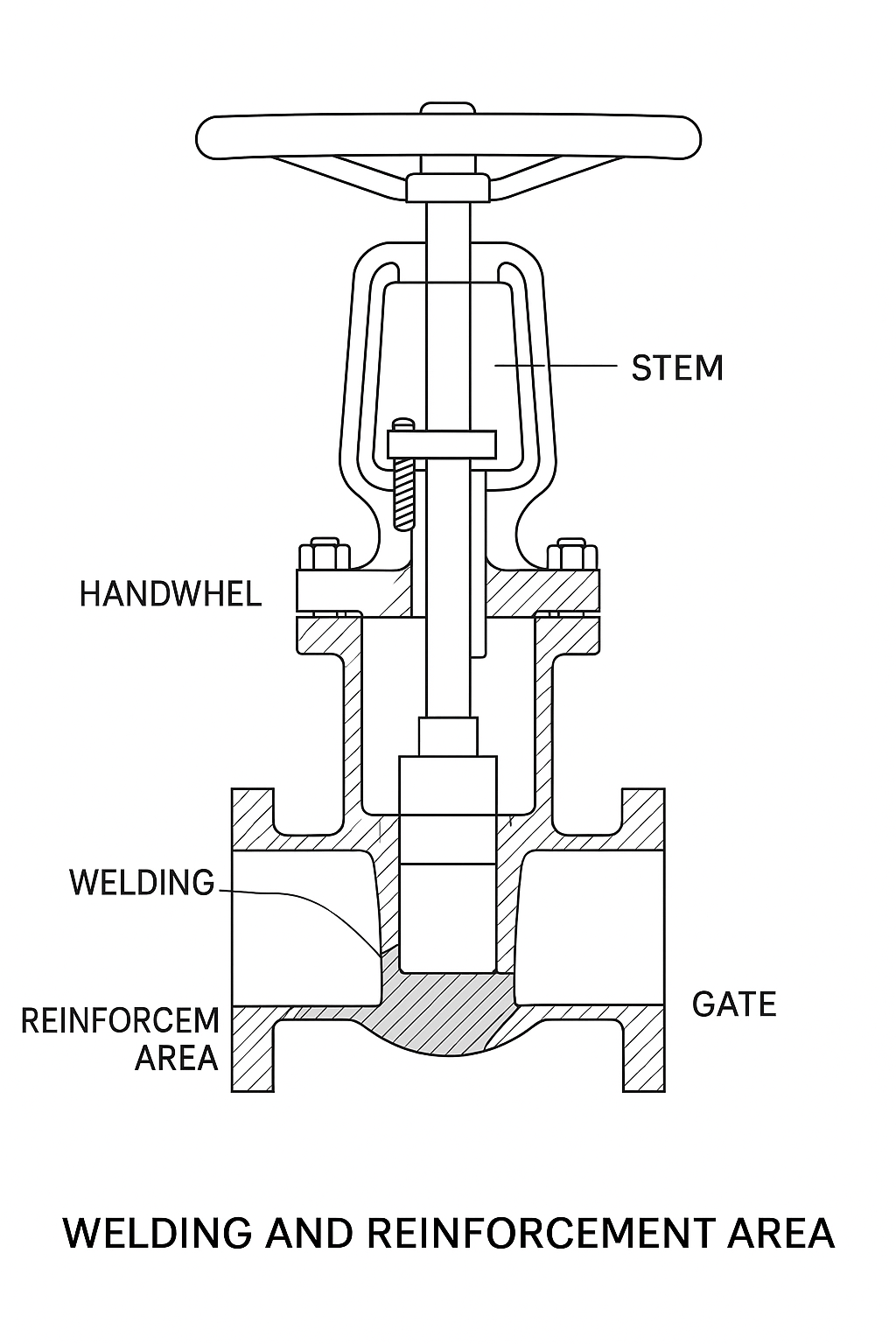

3.3 Weld Reinforcement of Sealing Gap

In cases of persistent leakage:

Dismantle the valve handwheel and yoke.

Fully open the valve.

Expose the press ring and weld the gap between press ring and valve body (5–8 mm weld width, 45° weld angle).

Grind and reassemble carefully.

Illustration 4: Weld Repair on Pressing Ring Area

3.4 Actuator Zero-Position Adjustment

Manually operate the valve to fully open/close it. Then recalibrate actuator zero-point to ensure it aligns with full travel range.

3.5 Body Repair or Factory Return

If the valve body has serious defects (through-wall cracks or extensive porosity), return it to the manufacturer or replace the valve. For repairable defects, proper welding procedures must be followed, including post-weld stress relief and non-destructive testing (NDT).

4. Conclusion

Gate valve leakage—whether internal or external—requires prompt analysis and appropriate handling. Remedial actions include:

Increasing preload force

Online sealing with sealant injection

Gap welding by trained personnel

Checking and adjusting actuator travel

Manufacturer-level repair for casting defects

Proactive inspection and proper maintenance strategies can minimize the occurrence of leakage, extend valve life, and ensure system safety.