“Just when I got the hang of 4–20 mA signals and HART protocol, here comes APL?”

Yes, the pace of innovation in industrial automation is fast—sometimes faster than your smartphone updates. So what exactly is APL? What makes APL-based instruments different from traditional ones? And why are more and more factories embracing this new technology?

What is APL and What is an APL Instrument?

APL (Advanced Physical Layer) is an Ethernet physical layer technology defined in the ISO/OSI model. It enables two-wire Ethernet communication that integrates data transmission, power supply, and intrinsic safety, making it ideal for hazardous industrial environments.

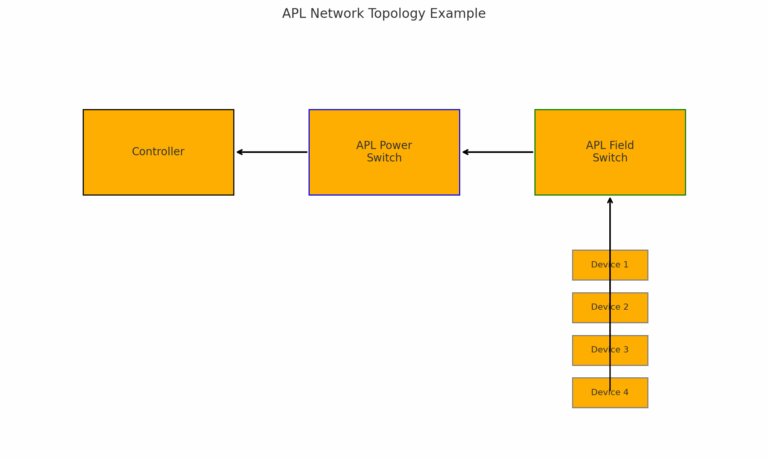

An APL instrument is a field device that uses this two-wire Ethernet technology. It is typically integrated with APL field switches and APL power switches. A single controller can support:

31 APL power switches,

256 APL field switches,

Up to 3072 APL field instruments.

These devices transmit data and power over two wires using techniques like Manchester encoding, which enhances noise immunity and simplifies signal decoding.

Key Advantages of APL Technology

✅ Simplified System Architecture

Eliminates traditional control system interface cards

No need for copper cable trays

Reduces:

100% of system I/O cards

90% of cabinet space

80% of wiring costs

50% of project timeline

✅ Intrinsic Safety

APL meets intrinsic safety standards for explosive environments by limiting current, voltage, and power. This ensures safety even in case of device failure.

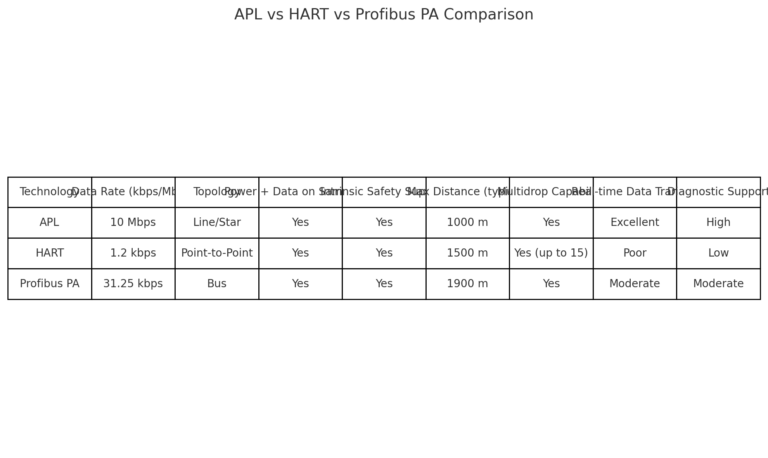

✅ Long Transmission Distances

Supports communication distances of over 1000 meters, making it ideal for large and distributed industrial facilities.

✅ High Bandwidth & Real-Time Performance

Offers high data throughput with low latency, suitable for real-time sensor readings and control signals in SIS (Safety Instrumented Systems).

✅ Strong Electromagnetic Interference Resistance

Thanks to advanced encoding and signal processing, APL is highly immune to EMI/RFI, which is common around motors and VFDs in industrial environments.

Applications in Safety Instrumented Systems (SIS)

1. Sensor and Actuator Integration

Data Acquisition:

APL connects field sensors like temperature, pressure, and level transmitters directly to control systems. For example, a temperature sensor in a reactor can transmit real-time data over APL to the SIS controller, which triggers alarms if the threshold is exceeded.

Actuator Control:

APL ensures fast, accurate delivery of commands to emergency shutdown valves or pressure relief devices. In the event of abnormal conditions, control commands can be transmitted instantly to shut off pipelines and contain hazardous materials.

2. System Architecture & Network Design

Distributed Architecture:

APL supports distributed SIS deployments across different plants or zones. Devices from multiple workshops can be connected via APL to a central control room for unified monitoring and management.

Redundancy and Fault Tolerance:

APL networks can easily be designed with redundant paths. In case one line fails, traffic can be rerouted to ensure uninterrupted communication, which is essential for high-reliability SIS applications.

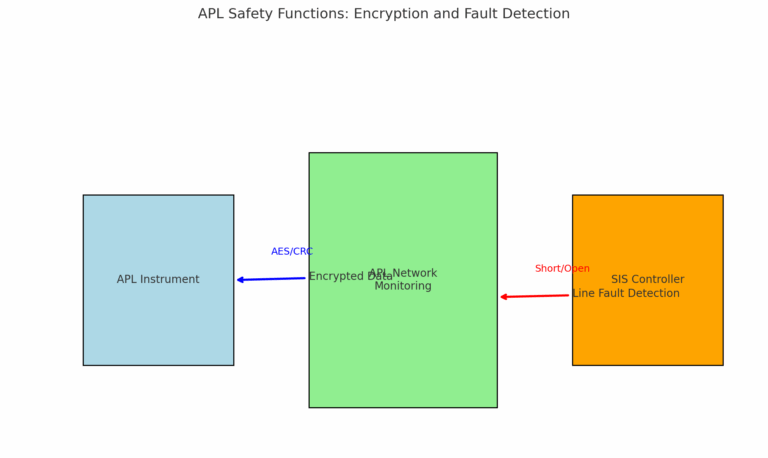

3. Enhanced Safety and Reliability

Fault Detection & Diagnostics:

APL supports real-time diagnostics such as wire breaks, shorts, and signal integrity monitoring. Combined with SIS self-diagnostics, this allows early detection of potential risks and faster maintenance response.

Data Integrity & Security:

APL uses encryption and checksum mechanisms to ensure data is not tampered with and is accessible only to authorized devices—crucial for cybersecurity and stable plant operations.

Value Brought by APL Instrumentation

End-to-end digital communication, from enterprise IT to field-level devices

Open architecture with concurrent access for control, diagnostics, asset management, configuration, and analytics

System-wide diagnostics, reduced cabling costs, faster commissioning, and shorter project cycles

Intelligent device configuration, diagnostics, and potential for edge-AI integration

Challenges to Consider

| Challenge | Description |

|---|---|

| Compatibility | Integration with legacy sensors, controllers, and systems may require additional interface adaptation. |

| Cost | Initial investment in APL devices, power modules, and cabling may be high, especially for SMEs. |

| Evolving Standards | APL must continuously adapt to newer safety, EMC, and communication standards. |

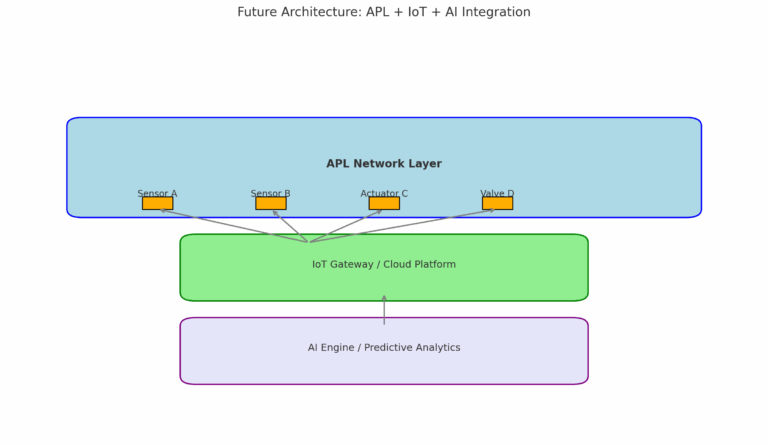

Future Outlook: APL + IoT + AI

APL has great potential when combined with emerging technologies like IoT and AI:

IoT allows intelligent asset tracking and remote monitoring

AI enables predictive diagnostics and risk analysis based on real-time data

As the technology matures and costs decrease, APL is expected to expand beyond traditional oil & gas or chemical industries into pharmaceuticals, food processing, and other sectors with strict safety requirements.