1. Introduction

In process industries such as chemical, pharmaceutical, petrochemical, and food processing, accurate documentation of system design is crucial. Among the most essential engineering drawings are the Process Flow Diagram (PFD) and the Piping and Instrumentation Diagram (P&ID). These diagrams help engineers and operators understand the process flow, equipment layout, and control logic of a plant.

2. What is a Process Flow Diagram (PFD)?

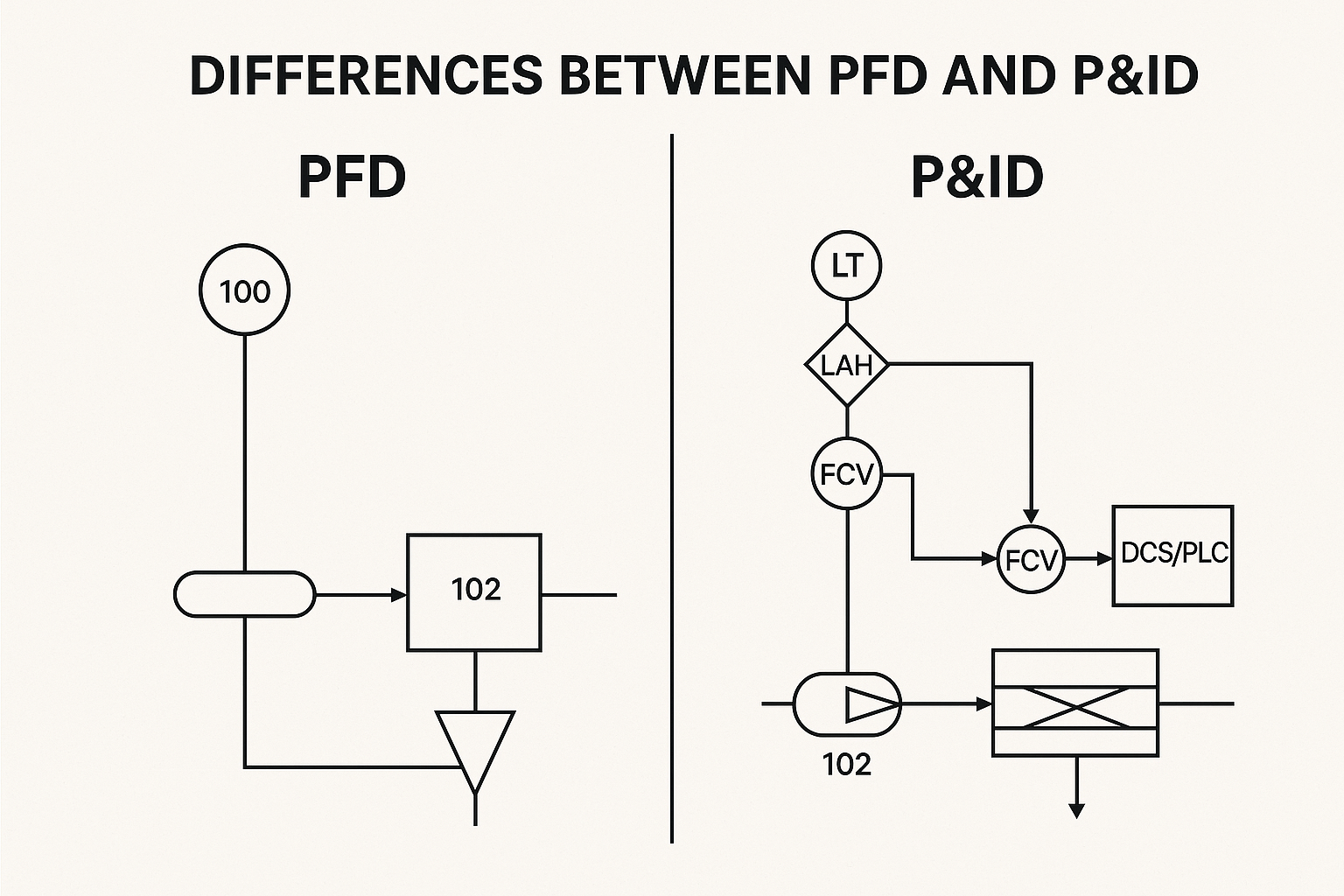

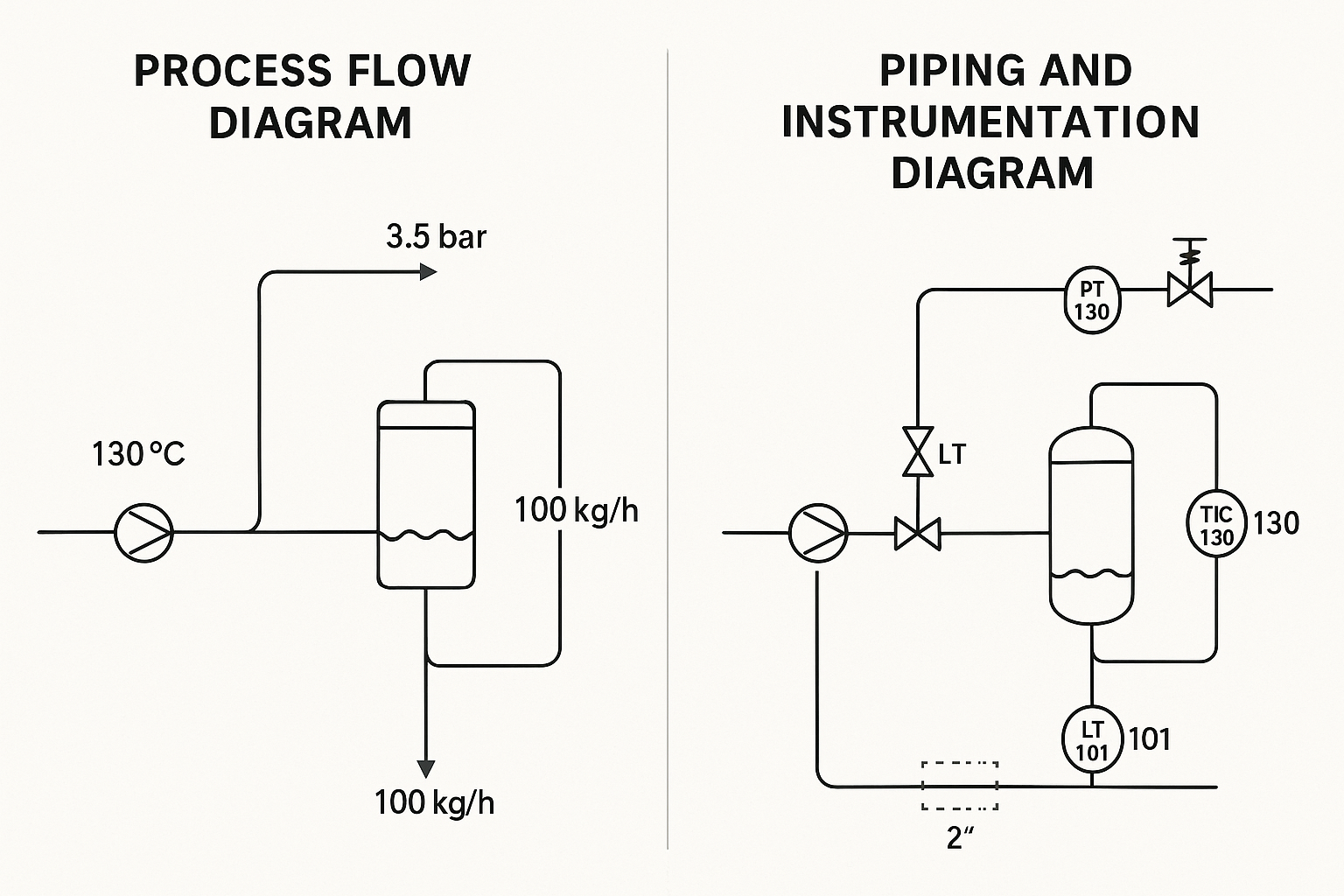

A Process Flow Diagram (PFD) provides a graphical representation of the major steps involved in a chemical or industrial process. It focuses on the high-level flow of materials and energy within a facility, showing major equipment, basic piping, and key control valves.

Key Features:

Displays main process routes and equipment

Shows mass and energy balances

Includes basic control elements

Omits minor piping details

Typical Components:

Pumps, compressors, reactors, heat exchangers

Major pipelines and flow directions

Temperature, pressure, and flow rate data

Control valves and process control loops (simplified)

3. What is a Piping and Instrumentation Diagram (P&ID)?

A Piping and Instrumentation Diagram (P&ID) provides a more detailed illustration than a PFD. It includes all process piping, instrumentation, control devices, insulation, and safety components. It is used in detailed design, installation, commissioning, and maintenance phases.

Key Features:

Detailed equipment symbols and tags

All piping lines with sizes and insulation details

Control valves, isolation valves, relief valves

Instrumentation (sensors, transmitters, indicators)

Sampling points, drain valves, and bypass lines

4. PFD vs. P&ID: Key Differences

| Aspect | PFD (Process Flow Diagram) | P&ID (Piping & Instrumentation Diagram) |

|---|---|---|

| Purpose | High-level overview | Detailed system design |

| Components | Major equipment and lines | All equipment, piping, valves, instruments |

| Instrumentation | Simplified | Fully detailed |

| Usage Stage | Process development, concept design | Detailed design, operations, maintenance |

| Standards | ISO 10628 | ISA S5.1, ISO 14617 |

5. Common PFD and P&ID Symbols

Symbols in both diagrams follow industry standards such as ISO, ANSI, and ISA. Below are examples:

Valves: Gate, globe, control, check

Equipment: Pumps, compressors, tanks, exchangers

Lines:

Solid: Process piping

Dashed: Signal or pneumatic lines

Instruments: Temperature transmitter (TT), pressure indicator (PI), flow control valve (FCV)

6. Standard Guidelines and References

ISO 10628: Flow diagrams for process plants

ISO 14617: Graphical symbols for diagrams

ISA S5.1: Instrumentation symbols and identification

ANSI/ISA-5.4: Instrument loop diagrams

7. Application in Industry

PFDs and P&IDs are critical in:

Engineering design packages

Construction and installation plans

Process optimization and troubleshooting

Regulatory compliance and safety reviews

8. Conclusion

Understanding the distinctions and applications of PFDs and P&IDs is fundamental in industrial process engineering. While PFDs offer a simplified overview of the process, P&IDs provide the granular detail necessary for installation, control, and maintenance. Both diagrams, when correctly developed and used, ensure safe, efficient, and reliable operations in process industries.