Introduction

In the field of industrial automation, the choice of communication protocols is a key factor that affects production efficiency, equipment coordination, and system stability. With the continuous advancement of technology, industrial communication protocols have evolved into a variety of standards. Among them, PROFINET, Modbus, and EtherCAT are the most widely used protocols across industries.

This article provides a detailed analysis of these three protocols—including their working principles, application scenarios, advantages, and limitations—to help PLC engineers and automation professionals make informed choices.

1. PROFINET Protocol Overview

1.1 Definition and Background

PROFINET (Process Field Network) is an industrial Ethernet communication protocol based on Ethernet technology and is considered the successor to PROFIBUS. It is designed to deliver efficient, real-time, and reliable data transmission, especially in production environments that demand high-speed control and coordination.

PROFINET is maintained by the international organization PI (PROFIBUS & PROFINET International) and is widely used in industries such as automotive, electronics, chemicals, and pharmaceuticals.

1.2 Working Principle

PROFINET operates on standard Ethernet hardware (e.g., switches, network cards) and uses a layered architecture:

Application Layer: Manages communication functions for devices.

Transport Layer: Manages data transmission and protocol operations.

Data Link Layer: Uses standard Ethernet frames for communication.

There are two main communication modes:

PROFINET IO: For real-time communication, including RT (Real-Time) and IRT (Isochronous Real-Time) modes, used between PLCs and field devices.

PROFINET CBA: For component-based automation, suitable for modular and distributed automation systems.

1.3 Advantages and Disadvantages

Advantages:

High real-time performance suitable for fast control systems.

Strong compatibility with other Ethernet-based systems.

Flexible deployment, supporting plug-and-play and dynamic device configuration.

Disadvantages:

Higher cost due to required hardware support.

Bandwidth consumption may be high under heavy network load.

1.4 Typical Applications

Automotive manufacturing

Electronic assembly lines

PLC and field device integration

Industrial robotics

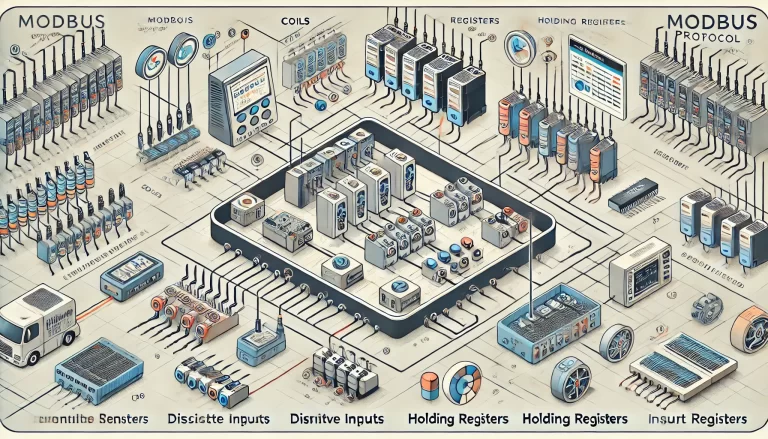

2. Modbus Protocol Overview

2.1 Definition and Background

Modbus is an open-source communication protocol originally developed by Modicon in 1979. It is widely used in industrial automation due to its simplicity, reliability, and ease of implementation. It follows a master-slave architecture and supports both serial and Ethernet communications.

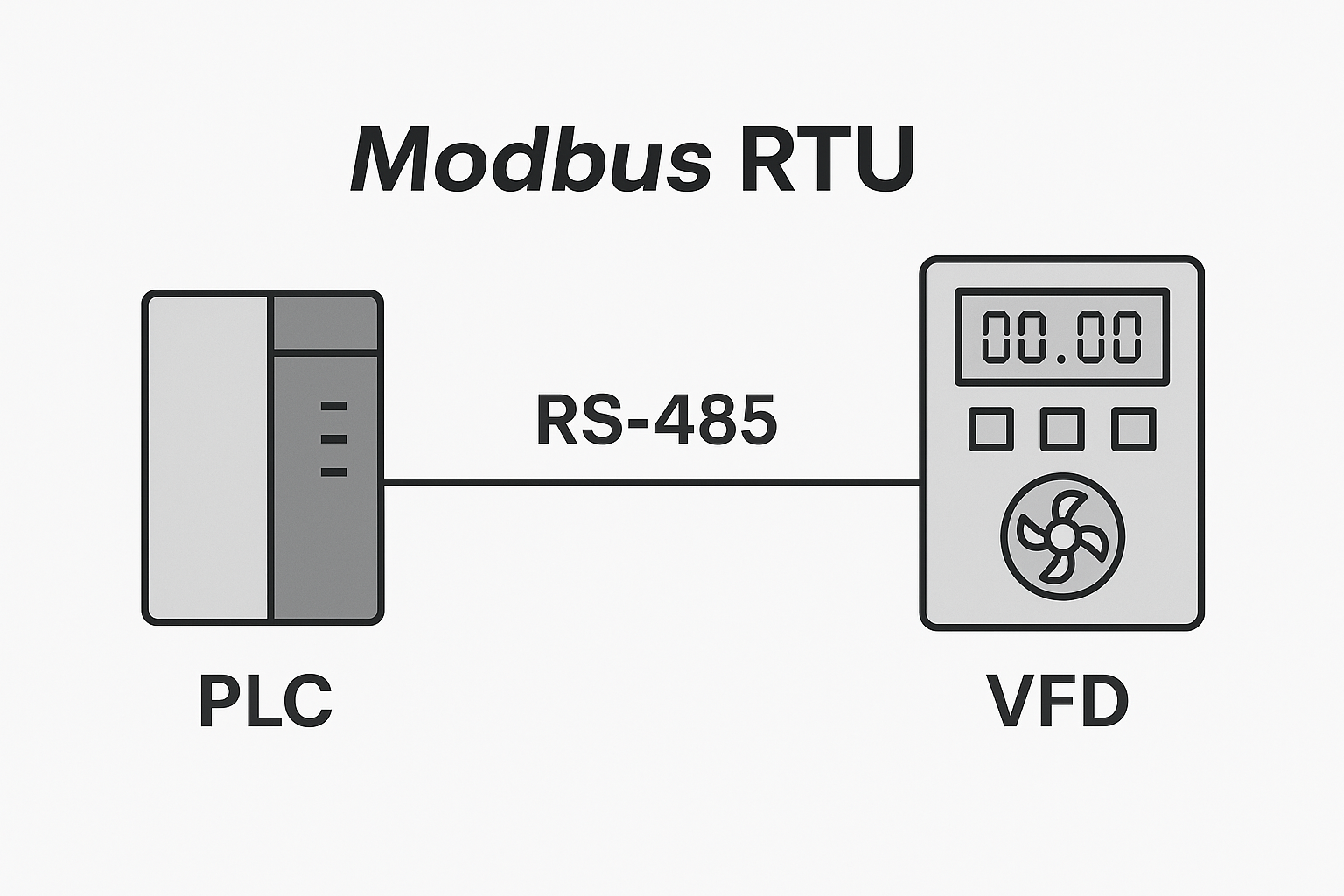

Common Modbus versions include:

Modbus RTU: Serial-based and widely used.

Modbus ASCII: Uses ASCII characters; suitable for long-distance transmission.

Modbus TCP: Ethernet-based; suitable for modern network environments.

2.2 Working Principle

Modbus is a request-response protocol, where the master sends a command and the slave responds. Communication involves device addresses, function codes, data, and CRC error-checking.

Address range: 0–247

Each device supports specific function codes (e.g., read/write registers).

2.3 Advantages and Disadvantages

Advantages:

Simple to implement, with low development and maintenance costs.

Highly compatible with devices from various manufacturers.

Reliable in basic control applications.

Disadvantages:

Low speed compared to modern Ethernet-based protocols.

Limited real-time capability.

Restricted scalability due to master-slave topology.

2.4 Typical Applications

Water treatment plants

Petrochemical facilities

Power distribution systems

Basic process control environments

3. EtherCAT Protocol Overview

3.1 Definition and Background

EtherCAT (Ethernet for Control Automation Technology) is a real-time Ethernet protocol developed by Beckhoff Automation in 2003. It is specially designed for high-performance control applications that require ultra-fast communication and precise synchronization.

Unlike traditional Ethernet, EtherCAT uses “on-the-fly” processing, allowing each device to extract and insert data while the frame passes through, minimizing latency.

3.2 Working Principle

Unlike Ethernet that relies on switches, EtherCAT uses a ring or line topology and processes data in real-time while the frame travels through each device. This allows data to be read and written with minimal delay.

EtherCAT supports:

Deterministic communication

Ring topology for redundancy

Distributed clock synchronization

3.3 Advantages and Disadvantages

Advantages:

Ultra-low latency due to on-the-fly data processing.

High bandwidth and throughput efficiency.

Excellent scalability with flexible network topology.

Disadvantages:

More complex to implement, requiring specific hardware and configuration.

Compatibility issues with legacy systems.

3.4 Typical Applications

Precision servo systems

CNC machines

High-speed packaging lines

Real-time robotic control

Conclusion

In modern industrial automation, PROFINET, Modbus, and EtherCAT each serve different needs:

| Protocol | Real-Time Performance | Complexity | Cost | Compatibility | Ideal Use Case |

|---|---|---|---|---|---|

| PROFINET | High | Medium | High | Strong | General automation, production lines |

| Modbus | Low | Low | Low | Excellent | Basic control, legacy systems |

| EtherCAT | Very High | High | Medium | Moderate | High-precision, fast-response control |

As automation systems become more complex, understanding the strengths and limitations of these protocols is crucial. Engineers should choose the right protocol based on application demands, real-time requirements, and cost constraints.